Advanced Anaerobic Digestion Technical Solutions for Treating Organic Waste and Food Scraps

In the modern urban and industrial landscape, the management of residual biomass has transitioned from a basic sanitation requirement to a primary pillar of the circular economy. As global populations rise and the industrial processing of food intensifies, the volume of organic residues—particularly kitchen waste and post-consumer discards—continues to grow, placing immense pressure on traditional disposal infrastructure. Central to the future of sustainable waste management is the implementation of advanced Anaerobic Digestion Technical Solutions. By integrating these processes into dedicated facilities for Organic Waste and Food Scraps, organizations can achieve the dual goals of significant solids reduction and the production of high-value renewable energy.

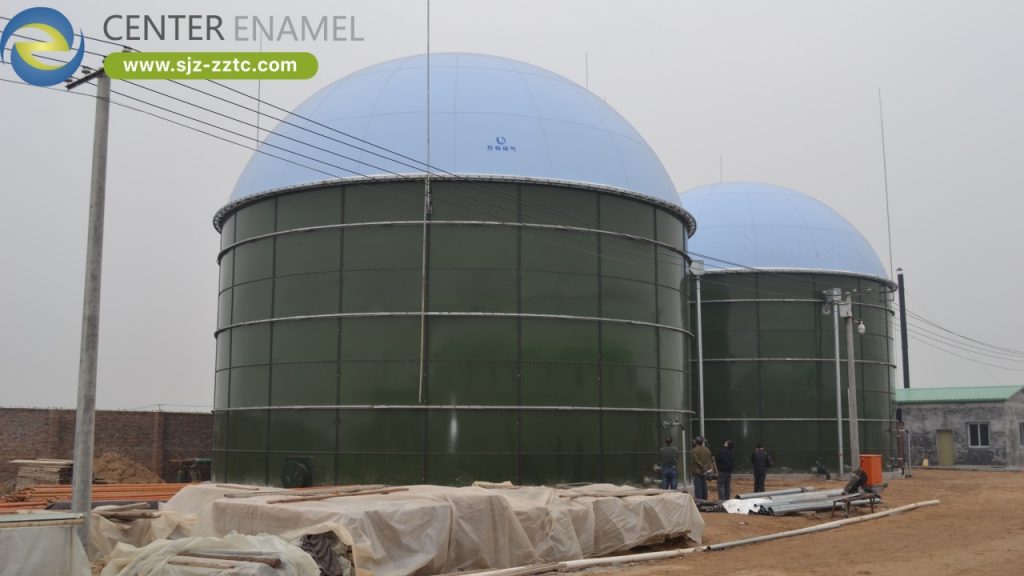

Shijiazhuang Zhengzhong Technology Co., Ltd, operating under the world-renowned brand Center Enamel, stands as a global leader in providing the specialized engineering infrastructure necessary for this transition. With over thirty years of innovation and a project footprint extending to more than one hundred countries, we provide the turnkey containment and processing solutions that make high-efficiency biological recovery a reality. Our expertise lies in the integration of Glass-Fused-to-Steel technology, high-performance Epoxy Coated Tanks, and advanced gas management systems, creating a cohesive platform designed to withstand the aggressive chemical nature of food waste while maximizing methane yields.

Technical Foundations: The Science of Treating Food Scraps

To optimize Anaerobic Digestion Technical Solutions, it is essential to understand the specific chemical and physical characteristics of the feedstock. Organic Waste and Food Scraps are complex matrices of proteins, lipids, and carbohydrates that require precise environmental control to unlock their energy potential.

1. The Four Stages of Biological Degradation

High-efficiency digestion relies on a sequence of four distinct biological stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. In the context of food waste, the hydrolysis stage is often rapid, leading to a quick drop in pH that can inhibit the sensitive methane-producing microorganisms if not managed correctly. Professional EPC services ensure that the reactor environment is perfectly buffered to support these sensitive microbial communities throughout the process.

2. Pre-treatment and Impurity Removal

Food scraps often arrive at the facility mixed with non-organic impurities such as plastics or glass. Advanced solutions integrate mechanical pre-treatment stages to shred, screen, and homogenize the feedstock. This ensures that the material entering the reactor is a uniform slurry, maximizing the surface area available for microbial attack and preventing the accumulation of heavy sediments within the containment vessels.

Core Infrastructure: GFS and Epoxy Coated Tank Solutions

A successful project for Organic Waste and Food Scraps requires containment infrastructure that can handle the aggressive nature of decomposing biomass and the mechanical demands of continuous industrial operation.

1. Glass-Fused-to-Steel (GFS) Technology

Our flagship GFS tanks are the global benchmark for the core anaerobic reactor. By fusing high-tech glass enamel to specialized steel at high temperatures, we create a material that combines the structural strength of steel with the chemical inertness of glass. These tanks offer unparalleled resistance to the organic acids generated during the rapid acidification of food waste. Their modular bolted design allows for rapid site assembly, which is vital for projects looking to meet tight construction windows in urban environments.

2. Epoxy Coated Tanks: High-Performance Industrial Storage

As a critical part of our infrastructure portfolio, Center Enamel’s Epoxy Coated Tanks provide an excellent solution for various auxiliary and storage stages within the treatment plant.

Advanced Coating Technology: Our epoxy tanks utilize a high-specification electrostatic powder coating process. This results in a smooth, durable finish that provides excellent resistance against a wide range of industrial chemicals and organic residues.

Versatile Application: These tanks are ideal for equalization, storage of treated digestate, or as pre-treatment vessels for incoming slurry. They offer a cost-effective yet highly durable alternative where high corrosion resistance is essential.

Factory-Controlled Quality: Every tank is manufactured under strict conditions to ensure consistent coating thickness and superior bond strength, providing a reliable long-term storage solution.

3. Aluminum Dome Roofs: Maintenance-Free Protection

For the storage of treated digestate or process water where gas capture is not the primary requirement, Center Enamel provides specialized Aluminum Dome Roofs. These self-supporting geodesic structures are a vital component of modern Anaerobic Digestion Technical Solutions. Constructed from high-strength aluminum alloy, they are naturally resistant to corrosion and require no internal support columns. They provide essential odor control—a critical factor for facilities located near residential areas—and prevent rainwater from diluting the nutrient-rich organic fertilizer produced at the end of the process.

Advanced Gas Management: Double Membrane Roof Systems

In any application of Anaerobic Digestion Technical Solutions, the efficient capture and pressure regulation of the produced biogas are critical for achieving a positive return on investment. Center Enamel’s Double Membrane Roofs are engineered as a dynamic, integrated gas management solution.

1. Dual-Layer Pressure Control

The system uses an inner membrane for gas storage and a constantly pressurized outer membrane for structural protection. This ensures that the anaerobic reactor maintains a consistent internal pressure, protecting the biological process and the tank structure from mechanical stress.

2. Gas Integrity and Safety

Our membranes are UV-stabilized and chemically resistant, ensuring they can withstand the aggressive vapors found in the anaerobic digestion of Organic Waste and Food Scraps while providing an airtight seal for methane capture. High-precision sensors track gas levels in real-time, feeding data back to the plant management system to optimize power generation.

Sustainability and Economic ROI for Waste Projects

Implementing advanced Anaerobic Digestion Technical Solutions through Center Enamel’s EPC services is a strategic economic decision for any modern industrial or municipal facility:

Energy Autonomy: By generating power on-site from food scraps, facilities can significantly reduce their reliance on expensive grid electricity and fossil fuels.

Waste Diversion Savings: The process transforms a costly waste disposal problem into a high-value commodity, significantly reducing landfill gate fees and transport costs.

Carbon Mitigation: Capturing methane allows companies to meet their sustainability targets and align with global environmental standards, often qualifying the project for green energy incentives.

Global Project Excellence: Center Enamel Project Cases

Our expertise in providing comprehensive solutions for the treatment of Organic Waste and Food Scraps is proven through successful installations:

Shandong Heze Biogas Project This major initiative utilized 3 units of our high-performance GFS tanks. The project successfully transforms concentrated organic residues into a stable energy stream, demonstrating the reliability of our integrated gas storage systems.

Inner Mongolia Hinggan League Bio-Natural Gas Project In a region characterized by extreme temperature fluctuations, this installation integrated 4 units of our bolted steel tanks. These vessels and their Double Membrane Roofs provide the stable environment necessary for the high-efficiency production of bio-natural gas, even under heavy snow loads.

Jiangsu Xuzhou Biogas Project This project involved the deployment of 4 units of our advanced containment technology. It serves as a model for how professional EPC services can be used to rapidly build the essential infrastructure needed for industrial energy recovery from diverse organic waste sources.

Leading the Future of Waste Recovery

The implementation of advanced Anaerobic Digestion Technical Solutions for the treatment of Organic Waste and Food Scraps represents a transformative step toward a more sustainable and resilient urban energy landscape. By converting a byproduct into a renewable energy asset, facilities can protect their local environment while securing their energy future.

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are dedicated to providing the innovation and engineering excellence that make these projects a success. From our premier GFS tanks and high-performance Epoxy Coated Tanks to our specialized gas management systems and Aluminum Dome Roofs, we offer a total containment solution designed for the future of industrial sustainability. Our commitment to quality and modular efficiency ensures that every project we undertake is built to perform and engineered to last.