Bio-CNG Production From Rice Straw: A Sustainable Path to Renewable Energy

The global energy landscape is currently undergoing a paradigm shift. As nations strive to meet stringent decarbonization targets and enhance energy security, the focus has moved toward diversifying the Renewable Energy portfolio. While wind and solar have seen significant growth, the potential of organic waste—specifically agricultural residues—remains one of the most promising yet underutilized resources. Among these, rice straw stands out as a high-volume byproduct of global food production that, when managed correctly, becomes a cornerstone for Bio-CNG Production From Rice Straw.

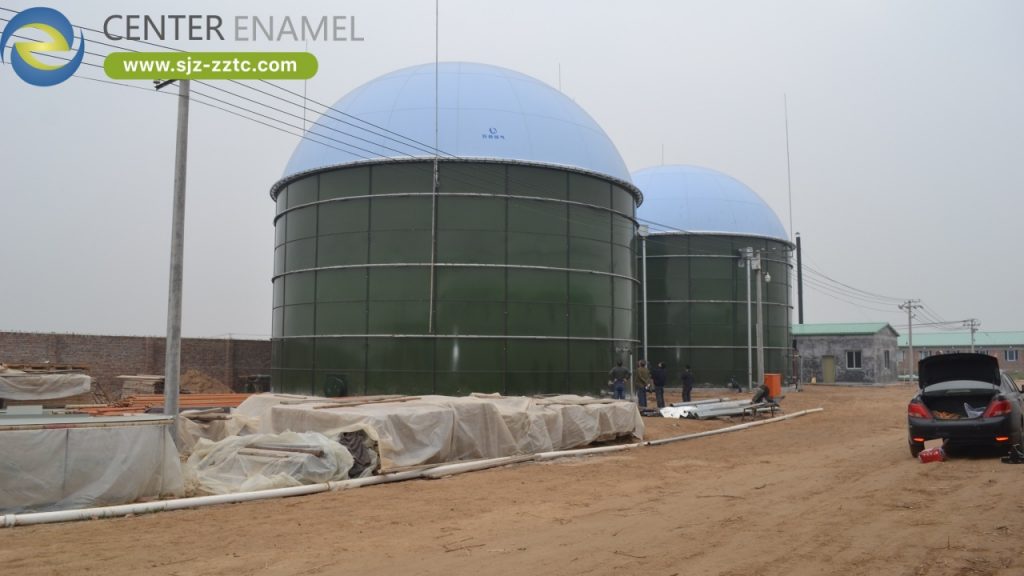

Shijiazhuang Zhengzhong Technology Co., Ltd, operating under the renowned brand Center Enamel, is at the forefront of this industrial evolution. As a premier manufacturer of Glass-Fused-to-Steel (GFS) tanks and integrated storage solutions, we provide the foundational infrastructure required to convert lignocellulosic waste into high-value biomethane. This article provides an in-depth look at the technical, environmental, and economic pathways of this sustainable energy transition.

The Global Shift to Renewable Energy and the Bio-CNG Opportunity

The urgent need to mitigate climate change has elevated Renewable Energy from a secondary alternative to a primary strategic necessity. Fossil fuel dependency not only contributes to atmospheric pollution but also creates economic volatility. In this context, Bio-CNG (Bio-Compressed Natural Gas) has emerged as a direct, drop-in replacement for conventional natural gas, suitable for transportation, industrial heating, and power generation.

Unlike intermittent energy sources, biogas-derived energy is dispatchable and constant. Bio-CNG Production From Rice Straw is particularly significant in agricultural economies. Every year, massive quantities of rice straw are generated. In many regions, the traditional disposal method is open-field burning, which releases substantial amounts of carbon dioxide, carbon monoxide, and particulate matter into the atmosphere, leading to severe air quality degradation and respiratory health issues for local populations.

By capturing this straw and processing it through anaerobic digestion, we achieve a "triple win": waste management, pollution reduction, and the production of clean, green energy.

Understanding the Process: Bio-CNG Production From Rice Straw

Converting a fibrous material like rice straw into a gaseous fuel requires a sophisticated, multi-stage biochemical process. The complexity lies in the structural composition of the straw, which is primarily composed of cellulose, hemicellulose, and lignin.

1. Collection and Pretreatment

The first challenge in Bio-CNG Production From Rice Straw is logistics and material preparation. Rice straw is bulky and has low bulk density. Once collected, it must undergo mechanical pretreatment. Shredding and grinding increase the surface area available for microbial attack. Because lignin acts as a protective shield around the fermentable sugars, advanced chemical or biological pretreatments are often employed to "unlock" the straw's energy potential. This stage often utilizes specialized stainless steel or epoxy-coated tanks to handle the varying acidity and moisture levels during hydrolysis.

2. Anaerobic Digestion (The Heart of the System)

The pretreated straw is fed into a primary reactor—typically a Continuous Stirred-Tank Reactor (CSTR). In this oxygen-free environment, complex consortia of bacteria break down the organic matter through four distinct phases: hydrolysis, acidogenesis, acetogenesis, and methanogenesis.

The goal is to maximize the yield of methane while managing the high solids content typical of straw feedstock. Maintaining stable internal temperatures and a neutral acidity level is crucial. This is where the structural integrity and thermal properties of the containment vessel become the most critical factors for project success.

3. Gas Cleaning and Upgrading

The raw biogas produced in the digester consists primarily of methane and carbon dioxide, along with impurities like water vapor and hydrogen sulfide. To reach the standards required for Bio-CNG, the gas must be upgraded. Carbon dioxide and hydrogen sulfide are removed through various technologies such as membrane separation or water scrubbing. The resulting high-purity biomethane is then compressed to a high-pressure state, becoming Bio-CNG, ready for injection into the gas grid or for use in vehicle fuel stations.

Center Enamel: Engineering the Foundation of Green Energy

At Center Enamel, we understand that a Bio-CNG plant is only as reliable as its containment. The aggressive nature of anaerobic digestion, combined with the abrasive characteristics of rice straw, demands materials that exceed conventional standards.

1. Glass-Fused-to-Steel (GFS) Technology

Our GFS tanks are the global benchmark for anaerobic digesters. The process involves fusing a high-tech glass enamel coating to a specialized steel substrate at extreme temperatures. This fusion creates a chemical bond that combines the strength and flexibility of steel with the extraordinary corrosion resistance of glass.

Corrosion and Abrasion Resistance: Rice straw contains significant amounts of silica, which can be abrasive to tank walls. The hard, glossy surface of our enamel coating resists both the chemical attack of organic acids and the physical wear of circulating solids.

Modular Construction: Our bolted design allows for rapid deployment in rural agricultural zones. Panels are manufactured in our ISO-certified facility and assembled on-site with high-grade fasteners, eliminating the need for complex welding and reducing the overall construction timeline.

Longevity: Designed for a service life spanning several decades, GFS tanks provide the lowest total cost of ownership in the Renewable Energy sector.

2. Material Diversity for Specialized Needs

While GFS is the "gold standard" for digesters, a comprehensive Bio-CNG Production From Rice Straw facility requires a variety of specialized vessels:

Stainless Steel Tanks: For pre-treatment zones where high acidity levels or specific chemical catalysts are used, our stainless steel bolted tanks provide superior resilience and hygiene.

Fusion Bonded Epoxy Tanks: For auxiliary water storage, fire protection, or low-corrosivity effluent management, our epoxy-coated tanks offer a cost-effective and durable solution that integrates seamlessly with the rest of the facility.

Advanced Roofing Systems: Maximizing Efficiency and Safety

A critical component of any biogas facility is the roof. In Bio-CNG Production From Rice Straw, the roof serves as both a weather barrier and a sophisticated gas management system.

1. Double Membrane Roofs: The Integrated Gas Holder

For primary and secondary digesters, our Double Membrane Roofs are indispensable. This system consists of an inner membrane that stores the gas and an outer membrane that provides structural protection and maintains a constant air pressure buffer.

Gas Tightness: The advanced membrane materials are engineered to prevent the leakage of methane, ensuring maximum energy capture and environmental safety.

Pressure Management: The flexible nature of the inner membrane allows it to expand and contract based on gas production rates, providing a crucial buffer for the upgrading system.

2. Aluminum Dome Roofs: Protection for Auxiliary Storage

In the later stages of the process, specifically for digestate storage and water management, our Aluminum Dome Roofs offer an unparalleled solution.

Maintenance-Free Durability: Aluminum is naturally resistant to the outdoor elements. Unlike steel roofs that may require repainting, our aluminum domes remain structurally sound and aesthetically pleasing for decades.

Odor Control: By sealing post-digestion tanks, Aluminum Dome Roofs help contain residual odors, ensuring the facility remains a "good neighbor" in agricultural and residential communities.

Clear Span Design: The geodesic design allows for large diameters without the need for internal support columns, which is ideal for large-scale digestate storage vessels.

Economic Resilience and the Circular Economy

The transition to Bio-CNG Production From Rice Straw is supported by a robust economic logic. Beyond the environmental benefits, these projects create a circular agricultural economy.

1. Revenue Streams

Bio-CNG Sales: The primary revenue comes from selling high-purity biomethane to transportation fleets or gas utilities.

Organic Fertilizer: The byproduct of the process, known as digestate, is a nutrient-rich organic fertilizer. By returning this to the fields, farmers reduce their reliance on expensive chemical fertilizers, improving soil health and crop yields.

Carbon Credits: By preventing open-field burning and replacing fossil fuels, Bio-CNG projects often qualify for significant carbon offsets, providing an additional financial boost.

2. Local Community Support

Building these facilities creates high-quality technical jobs in rural areas. It provides farmers with an additional income stream for their waste straw and stabilizes local energy prices by utilizing locally produced fuel.

Global Project Portfolio: Proven Performance

Center Enamel’s expertise is backed by a vast history of successful installations. In the field of Renewable Energy, we have provided the core containment for projects that transform complex feedstocks into clean power. Our equipment is certified to international standards including AWWA D103, OSHA, and NSF/ANSI 61.

The following project cases demonstrate our capacity to deliver high-quality solutions for advanced biogas and bio-natural gas applications:

Inner Mongolia Hinggan League Bio-Natural Gas Project: This sophisticated facility, focusing on large-scale conversion of organic waste into high-quality biomethane, utilizes 4 units of our high-performance GFS tanks. The project highlights our ability to support high-solid digestion processes in challenging climates.

Jiangsu Xuzhou Biogas Project: A landmark installation in the agricultural sector, this project features 4 units of our bolted steel tanks. It serves as a prime example of how modular construction can be utilized to rapidly build large-scale energy infrastructure.

Shandong Heze Biogas Project: Dedicated to regional waste management and energy recovery, this project successfully integrated 3 units of our GFS vessels. These tanks provide the essential structural stability required for continuous anaerobic digestion.

A Greener Future with Center Enamel

The pathway to a sustainable world requires innovation, dedication, and the right technology. Bio-CNG Production From Rice Straw is more than just a technical process; it is a vital part of the global strategy for Renewable Energy and climate mitigation. By turning a massive waste burden into a high-value energy asset, we are protecting our environment while powering our economies.

At Shijiazhuang Zhengzhong Technology Co., Ltd, we are committed to providing the world-class containment and roofing systems that make these projects possible. From our industry-leading GFS tanks to our specialized Aluminum Dome Roofs and Double Membrane Roofs, we offer a total solution for the renewable energy industry.

As we look forward, we continue to invest in research and development, ensuring that our materials and engineering remain at the absolute cutting edge of the waste-to-energy sector. Together, we can build a cleaner, more resilient energy future.