Biogas Energy Solutions for Slaughterhouse Wastewater Treatment Projects

The meat processing industry is globally indispensable, yet it generates one of the most challenging and concentrated wastewater streams: slaughterhouse effluent. This liquid waste, rich in blood, fat, protein, suspended solids, and microbial content, presents a profound dual challenge. Environmentally, its massive Chemical Oxygen Demand (COD) threatens waterways, while operationally, its disposal consumes significant capital and energy.

The modern paradigm for the meat industry demands a shift from costly treatment to profitable resource recovery. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) is the leading infrastructure partner enabling this transition through robust Biogas Energy Solutions integrated within Slaughterhouse Wastewater Treatment Projects. We specialize in providing the foundation for high-efficiency anaerobic digestion, which scientifically converts the effluent’s extreme organic load directly into methane-rich biogas—a valuable, self-generated fuel source.

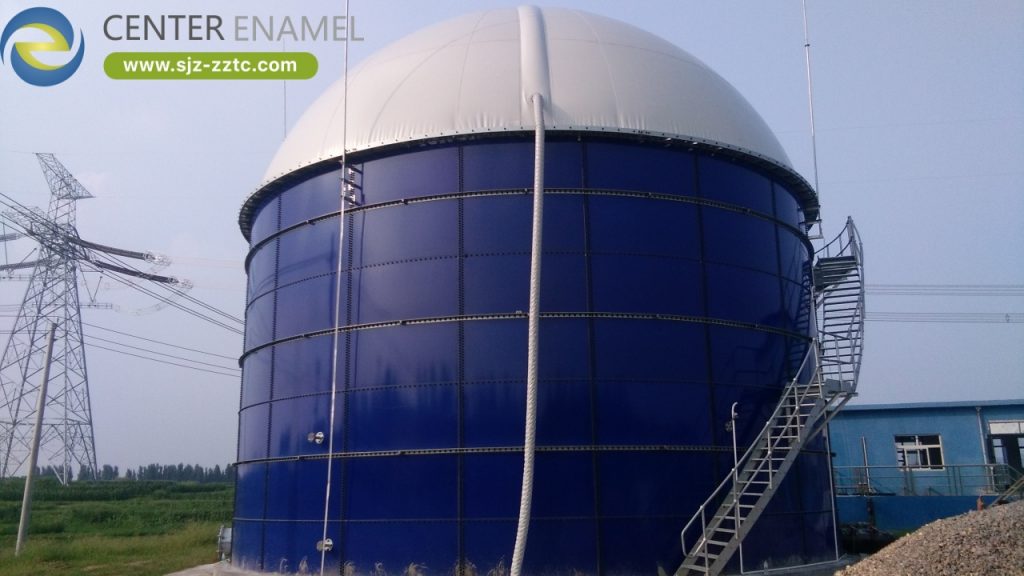

By utilizing our durable and chemically resilient Glass-Fused-to-Steel (GFS) tanks to house these critical anaerobic digesters, Center Enamel delivers a compact, scalable, and secure system. This strategy allows meat processors to achieve stringent environmental compliance, mitigate foul odors, and secure energy independence, transforming their most challenging byproduct into a permanent, operational asset.

The Extreme Complexity of Slaughterhouse Effluent

Slaughterhouse Wastewater Treatment Projects must contend with a unique and complex matrix of organic components that demand specialized pre-treatment and digestion technology.

1. High Organic Strength and Inhibition Risks

Slaughterhouse wastewater possesses a composition that is both ideal for energy recovery and highly challenging for biological treatment:

Extreme Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD): The high concentrations of blood, fats, proteins, and gut contents result in some of the highest COD and BOD values in industrial wastewater. This massive organic load, if harnessed correctly, offers an excellent fuel yield for Biogas Energy Solutions.

High Fat, Oil, and Grease (FOG) Content: FOG is a major characteristic of this effluent. If not efficiently pre-treated (often via dissolved air flotation), FOG can form surface scum layers, inhibit microbial activity, and clog mechanical components within the digester, reducing stability and biogas yield.

High Nitrogen and Protein Content: The breakdown of high protein content (blood, tissue) leads to high concentrations of ammonia. While nitrogen is a necessary nutrient, excessive ammonia can be a potent inhibitor to the methane-producing microbes, demanding careful control of the digestion environment.

Fluctuating Flows: Production schedules, often involving concentrated wash-down phases, mean the wastewater flow and organic load can fluctuate rapidly, requiring a resilient and highly buffered digestion system.

2. Operational and Environmental Necessities

The implementation of Biogas Energy Solutions is driven by core regulatory and economic pressures in the meat industry:

Energy Consumption: Slaughterhouses are significant consumers of energy for refrigeration, steam sterilization, rendering, and ventilation. Generating power from biogas provides the most direct and reliable path to achieving substantial energy cost savings and self-sufficiency.

Odor and Public Health: Untreated slaughterhouse waste is a major source of extremely foul odors and poses significant public health risks due to pathogen content. Enclosed anaerobic digesters capture volatile organic compounds and methane, dramatically reducing odor and controlling emissions.

Regulatory Compliance: Environmental discharge limits for COD, suspended solids, and grease are strict. High-rate anaerobic digestion achieves a massive percentage reduction in the organic load, ensuring the mill can cost-effectively meet these standards.

Sludge Management: Traditional aerobic treatment of this waste results in large volumes of difficult-to-dewater biological sludge. Anaerobic digestion produces far less excess sludge, significantly simplifying the final disposal process and lowering associated costs.

The Solution: High-Rate Anaerobic Biogas Energy Solutions

The conversion of slaughterhouse effluent into renewable energy is achieved through specialized high-rate anaerobic digestion, the engine that powers Biogas Energy Solutions within these complex Slaughterhouse Wastewater Treatment Projects.

1. Optimizing Biogas Production and Utilization

The technological focus is on maximum methane recovery from the challenging feedstocks:

High-Rate Reactor Technology: Systems like the Expanded Granular Sludge Bed (EGSB) or specialized Continuous Stirred Tank Reactors (CSTRs) are preferred. EGSB, in particular, handles the high flow rates common in slaughterhouses and maintains a highly concentrated bed of granular sludge that is resilient against shock loading from high-strength components.

Methane Recovery: Within the digester, the high COD of the waste is rapidly consumed by microbes and converted into methane-rich biogas. This captured gas is the core of the Biogas Energy Solutions.

Energy Co-generation (CHP): The recovered biogas is purified (to remove corrosives like hydrogen sulfide) and fed into a Combined Heat and Power (CHP) unit. The CHP unit combusts the gas to generate electricity for running the plant’s motors, lighting, and ventilation. Crucially, it also captures the waste heat, which is essential for maintaining the digester’s optimal temperature (usually mesophilic) and often for use in the slaughterhouse’s hot water or rendering processes, maximizing the total energy efficiency.

2. Value Beyond Energy

The success of Biogas Energy Solutions extends to sustainable waste management:

Nutrient-Rich Digestate: The final liquid effluent (digestate) is stabilized, substantially reduced in organic load, and retains valuable plant nutrients (nitrogen, phosphorus). This can often be safely applied as a high-quality fertilizer to agricultural land, contributing to the circular economy model.

Pre-treatment Integration: Effective Slaughterhouse Wastewater Treatment Projects rely on integrated pre-treatment (like screening and flotation) to remove FOG and coarse solids before they reach the digester. The anaerobic stage then performs the bulk of the COD removal, making the subsequent, less energy-intensive aerobic polishing stage significantly smaller and cheaper to operate.

GFS Tanks: The Unwavering Foundation for Biogas Energy Solutions

For the challenging, corrosive environment of slaughterhouse waste digestion, the integrity of the containment vessel is paramount. Center Enamel’s Glass-Fused-to-Steel (GFS) tanks are the globally recognized standard for robust Biogas Energy Solutions in the meat processing sector.

Unmatched Durability Against Aggressive Effluent

GFS technology is specifically engineered to provide a long-term, fail-safe barrier against the harsh internal environment:

Ultimate Corrosion Resistance: The digestion of high-protein waste creates a highly corrosive environment rich in ammonia and hydrogen sulfide. The GFS coating—a molecularly fused, inert glass layer on high-strength steel—forms an impervious, non-porous chemical barrier. This protection guarantees the tank's structural life extends over decades without the costly corrosion and recoating cycles required by conventional materials.

Structural Strength and Integrity: GFS tanks are built from precision-engineered, high-strength steel panels, providing the necessary integrity to safely contain the immense volume and hydrostatic pressure of large-scale digesters, while securely handling the dynamic forces from continuous internal mixing required for heavy sludge and fat layers.

Guaranteed Gas-Tightness: The safe and efficient capture of the methane fuel is the economic key to Biogas Energy Solutions. The modular, bolted GFS design utilizes specialized, durable sealants and precision fitting to ensure a superior, permanent gas-tight seal. This maximizes methane recovery, ensuring both safety and optimal energy generation.

Operational and Economic Advantages

Choosing GFS provides strategic benefits that align with the high-volume, rapid-deployment needs of modern slaughterhouses:

Rapid, Reliable Installation: GFS components are factory-finished and bolted together on-site. This modular construction is significantly faster and less prone to delays than traditional concrete construction, minimizing operational downtime and accelerating the start of biogas and energy production.

Scalability and Flexibility: The modular GFS design allows for easy capacity expansion or modification as slaughterhouse production volumes increase, providing operational flexibility not possible with fixed, rigid structures.

Low Lifetime Maintenance: The smooth, inert glass surface resists scaling, fouling, and chemical attack, minimizing the need for internal inspection, cleaning, and major maintenance over its long lifespan, resulting in a substantially lower total cost of ownership.

Project Cases

Center Enamel is a global leader in providing GFS containment for the high-load industrial and animal agriculture sectors, facilitating advanced anaerobic digestion and successful Biogas Energy Solutions across demanding Slaughterhouse Wastewater Treatment Projects and related high-strength waste streams.

Muyuan Group Suining 4th Farm Livestock Wastewater Project: This project demonstrates our capacity to handle extremely high-volume, high-concentration animal waste streams, directly related to the organic load challenges of a slaughterhouse. The installation consisted of 2 units with a total capacity of 17,962 cubic meters, showcasing our ability to deliver substantial high-capacity containment for complex Biogas Energy Solutions.

Jiangxi Jiujiang Papermaking Wastewater Treatment Project: We supplied GFS containment for a major industrial project involving complex, high-volume organic effluent. This installation involved 2 units with a total capacity of 10,350 cubic meters, affirming our expertise in executing high-capacity projects where containment integrity for aggressive wastewater is essential.

Nine Dragons Paper Guangdong Dongguan Wastewater Treatment Project: We provided robust containment for a multi-unit industrial facility requiring large-scale wastewater management and resource recovery. This project consisted of 3 units with a total capacity of 6,973 cubic meters, further cementing our proven track record in supplying foundational infrastructure for diverse, high-strength industrial applications demanding reliable biogas recovery and high volume processing.

Conclusion: Sustainability and Profitability in the Meat Sector

For every Slaughterhouse Wastewater Treatment Project, the integration of Biogas Energy Solutions is the most powerful and sustainable pathway forward. It transforms the challenging, high COD effluent—rich in blood, fat, and protein—into a reliable, renewable source of methane-rich biogas and thermal energy.

By choosing Center Enamel’s Glass-Fused-to-Steel (GFS) tanks, meat processors secure a foundation of unmatched durability, chemical resilience, and guaranteed gas-tight integrity. This robust infrastructure is essential for efficient anaerobic digestion, ensuring maximized biogas recovery, long-term energy independence, minimal environmental footprint, and comprehensive compliance, turning effective waste management into a permanent, profitable competitive advantage.