Biogas Project EPC Contractor: Delivering Integrated Energy and Effluent Management for Livestock Manure

The global livestock industry is at a pivotal intersection: balancing increasing protein demand with the urgent necessity for sustainable, environmentally responsible manure and effluent management. Traditional disposal methods burden farms with escalating costs, regulatory non-compliance risks, and significant environmental challenges, particularly related to water pollution and greenhouse gas emissions.

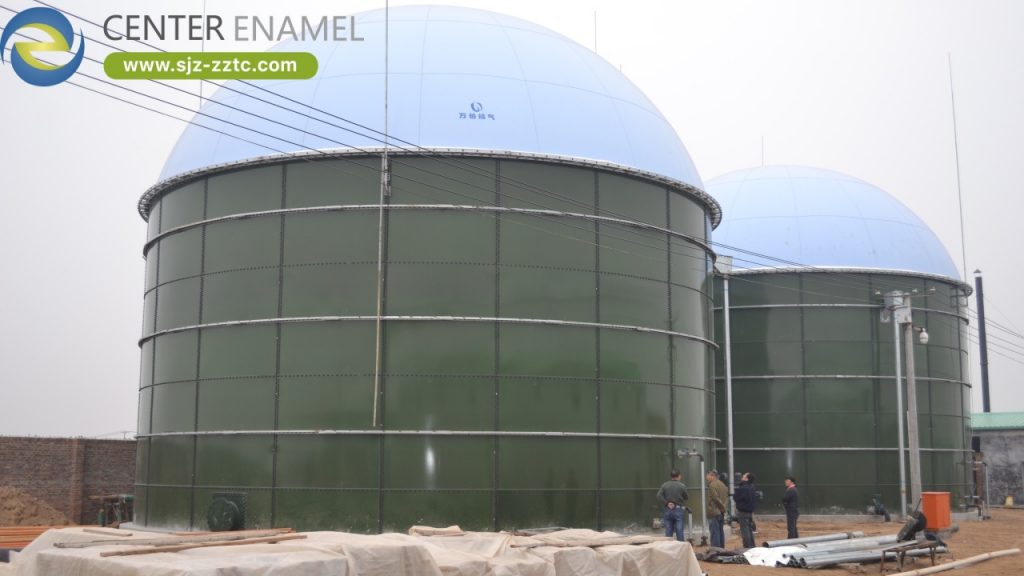

The solution lies in harnessing the organic energy within the waste stream. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) specializes in converting this liability into a sustainable asset. We are the definitive, full-scope Biogas Project EPC Contractor, providing end-to-end, integrated solutions that transform highly polluting Livestock Manure Treatment Projects into self-sufficient, energy-producing facilities.

Our expertise is founded on the guaranteed performance and long-term durability of our chemically resistant Glass-Fused-to-Steel (GFS) tanks. As your dedicated Biogas Project EPC Contractor, Center Enamel assumes total responsibility for the project lifecycle, delivering a fixed-price, high-efficiency system that ensures maximum methane yield, compliance with stringent effluent standards, and fosters genuine agricultural sustainability.

The Dual Challenge of Livestock Manure Treatment

A Livestock Manure Treatment Project faces two primary, complex challenges: managing the volume and composition of the manure stream, and executing the technical complexity of an energy-recovery system.

1. The Volatile Nature of Livestock Manure

Livestock manure streams, particularly from large-scale farming, present distinct challenges due to their composition:

High Solids and High Nitrogen Content: Manure contains significant amounts of bedding, undigested feed, and high concentrations of nitrogen compounds. This requires specialized pre-treatment, separation, and digestion techniques to prevent ammonia inhibition and optimize anaerobic bacteria activity.

High Pathogen and Odor Risk: Improperly managed manure is a major source of pathogens and intense odors, necessitating sealed, controlled treatment environments. Anaerobic digestion within gas-tight GFS tanks effectively stabilizes the organic material, reducing pathogens and nearly eliminating odor emissions.

Corrosive Environment: The continuous flow of manure slurry creates a physically abrasive and chemically corrosive environment. This requires construction materials like GFS that are engineered for decades of reliable service in this demanding application, resisting erosion, acidity level fluctuations, and the aggressive nature of the digestate.

2. The Necessity of the Biogas Project EPC Contractor Model

The successful delivery of a profitable and compliant Livestock Manure Treatment Project hinges on integrating multiple complex systems—from solids separation to energy generation—under a single point of accountability:

Holistic System Integration: A biogas facility is not a single piece of equipment; it's a complex chain involving feedstock reception, pre-treatment, anaerobic reactors, biogas cleaning, and energy utilization. Center Enamel, as the Biogas Project EPC Contractor, guarantees the seamless functionality of all these interdependent processes.

De-Risking Project Execution: The EPC structure provides the client with a predictable, fixed budget and an accelerated construction schedule, eliminating costly delays and financial uncertainties common when managing multiple contractors and vendors. We guarantee performance metrics, including biogas yield and final digestate quality.

Regulatory Compliance: Regulatory standards for effluent discharge and digestate land application are constantly tightening. Our EPC scope is designed to meet or exceed these standards, often integrating post-treatment polishing steps to ensure final effluent quality from the Livestock Manure Treatment Project is compliant.

Optimized Energy Utilization: Beyond simple combustion, we design comprehensive energy recovery systems, often utilizing Combined Heat and Power (CHP) units to maximize the efficiency of the biogas, using generated heat to maintain optimal reactor temperatures and electricity for farm operations or grid injection.

The GFS Foundation: Durability in Manure Treatment

The heart of an efficient Livestock Manure Treatment Project is the anaerobic digester, and its long-term integrity depends entirely on the containment material. Center Enamel's Glass-Fused-to-Steel (GFS) technology offers the non-negotiable solution for durability in the high-stress environment of manure digestion.

1. Engineered for Chemical and Physical Endurance

Our GFS tank technology ensures maximum reactor uptime and longevity:

Unmatched Corrosion Resistance: Manure slurry and the resulting digestate contain numerous corrosive organic acids and gaseous sulfur compounds. The molecular fusion of glass to steel creates a permanent, non-porous, inert barrier that resists these aggressive substances. This guaranteed resistance is critical for the long-term profitability of a Biogas Project EPC Contractor solution.

Gas-Tight Integrity: Maximum methane recovery is essential for economic viability. The precise manufacturing of our GFS panels and the robust industrial sealant systems we employ ensure a superior, permanent gas-tight seal throughout the tank structure, optimizing the capture of the valuable biogas produced from the Livestock Manure Treatment Project.

Resistance to Abrasion: Manure streams often contain high levels of sand and fibrous material that can physically abrade the tank walls. The hardness and smoothness of the GFS surface provide excellent resistance to wear and tear, maintaining the structural integrity of the digester over its long service life.

2. Process Design Excellence for Manure Feedstock

As a specialized Biogas Project EPC Contractor, we tailor the process to manage the high solids and nitrogen inherent in livestock manure:

Reactor Technology Selection: We deploy reactor types proven in high-solids applications, such as Complete Mix Anaerobic Digestion (CMAD) or innovative plug-flow designs. The choice depends on the specific rheology and Total Solids (TS) content of the manure, ensuring maximum contact between the substrate and the microbial community.

Pre-treatment and Mixing: Effective digestion relies on proper pre-treatment (e.g., solid-liquid separation) and powerful, low-energy mixing systems to ensure homogeneous heating and prevent stratification within the GFS tank. Our EPC scope guarantees these critical process steps are perfectly executed.

Temperature Control: Maintaining optimal mesophilic or thermophilic digestion temperature is key to maximizing methane yield. Our design integrates the GFS tanks with the CHP system to efficiently recover and utilize biogas heat, stabilizing the reactor environment against external weather conditions.

Comprehensive EPC Scope: From Waste Stream to Revenue Stream

Center Enamel’s full-scope EPC model extends far beyond tank supply. We manage every phase of the Livestock Manure Treatment Project, delivering a completely operational, guaranteed asset.

1. Engineering and Design (E)

The engineering phase is where project value is maximized, focusing on efficiency and compliance:

Feedstock Characterization and Yield Prediction: We conduct detailed analyses of the specific manure stream to accurately predict biogas yield and energy potential, forming the basis for the entire financial model of the Biogas Project EPC Contractor solution.

Detailed Process and Mechanical Design: Our in-house engineers design the complete system, adhering to strict international engineering standards (e.g., AWWA D103-09), optimizing the tank size, mixing systems, heating systems, and interface with farm operations.

Site-Specific Civil and Foundation Design: The EPC contract includes all civil works, guaranteeing the foundation design is perfectly suited for the specific soil conditions and the massive load of the large GFS reactors.

2. Procurement and Manufacturing (P)

Our control over the supply chain ensures superior quality and timely delivery:

In-House GFS Production: Center Enamel maintains one of the world’s leading GFS manufacturing facilities, ensuring rapid, high-volume, and certified-quality fabrication of the core reactor panels. This eliminates external manufacturing delays common in multi-contractor projects.

Global Equipment Sourcing: We procure all necessary balance-of-plant equipment—pumps, mixers, CHP units, gas handling equipment—from certified, high-quality global suppliers, guaranteeing component compatibility and reliability throughout the Livestock Manure Treatment Project.

Quality Assurance: All materials and components undergo stringent quality control checks, ensuring compliance with international certifications (e.g., ISO, NSF) and the highest standards required of a specialized Biogas Project EPC Contractor.

3. Construction and Commissioning (C)

The construction phase is executed to minimize site disruption and accelerate time-to-value:

Rapid, Modular Installation: The modular, bolt-together nature of GFS tanks allows for significantly faster on-site assembly compared to poured concrete, reducing disruption to essential farm operations and accelerating the path to energy production.

Certified Safety and Quality Control: Our experienced, safety-certified installation teams manage all on-site construction, mechanical installation, and piping, ensuring the highest standards of safety and quality control.

Guaranteed Commissioning: The EPC scope culminates in a guaranteed commissioning period, where we meticulously tune the process and train the client’s operational staff until the Livestock Manure Treatment Project meets all contracted performance guarantees for biogas yield and effluent quality.

Project Cases

Center Enamel is the globally trusted Biogas Project EPC Contractor, delivering high-performance, large-scale GFS containment solutions essential for modern waste-to-energy recovery. The scale and complexity of these projects, particularly those focused on high-load organic materials and biogas production, directly affirm our specialized capability for guaranteed success in any Livestock Manure Treatment Project.

The following flagship cases highlight our mastery in deploying multi-unit, high-capacity EPC solutions across major biogas and livestock operations:

Muyuan Group Suining 4 Farms Breeding Wastewater Project: This massive project involved supplying core containment infrastructure to manage the aggregated effluent from multiple large livestock farms. The solution demanded superior corrosion resistance and high-volume capacity to handle continuous, high-load organic streams from the Livestock Manure Treatment Project. This installation featured 2 units with an extraordinary total capacity of 17,962 cubic meters, showcasing our ability to deliver the largest and most robust GFS reactors required by a leading agricultural group under a demanding Biogas Project EPC Contractor requirement.

Inner Mongolia Hinggan League Bio-Natural Gas Project: As a major dedicated bio-natural gas facility, this project required highly specialized EPC execution to ensure maximized methane yield and reliable gas clean-up for pipeline injection. The complexity and cold-weather requirements of this site highlight our technical depth in designing and implementing systems that operate efficiently under challenging conditions. The facility comprised 4 units with a total capacity of 16,760 cubic meters, affirming our expertise in executing multi-tank, large-capacity projects essential for industrial-scale biogas generation.

Shandong Heze Biogas Project: This substantial biogas facility demanded resilient GFS containment to ensure long-term structural stability and gas-tight integrity for continuous power generation from organic feedstocks. The successful delivery demonstrates our mastery in engineering and constructing the core containment for systems designed to maximize energy recovery. The installation featured 2 units with a total capacity of 15,266 cubic meters, further cementing our proven track record in providing high-volume GFS solutions for major Biogas Project EPC Contractor mandates.

Conclusion: Securing Sustainability and Profitability

For the global livestock sector, the successful implementation of a manure-to-energy solution is no longer optional—it is a critical necessity for sustainability, public acceptance, and financial health. The high organic content of the waste stream represents an untapped energy reservoir that can transform a cost center into a revenue stream.

Center Enamel, as your specialized Biogas Project EPC Contractor, provides the guaranteed partnership required for this transformation. Our full-scope EPC model, anchored by the unmatched durability and chemical resilience of our Glass-Fused-to-Steel (GFS) tanks, eliminates technical risk and delivers a fully operational asset. This solution not only ensures regulatory compliance for your Livestock Manure Treatment Project but also locks in long-term energy independence and maximizes the economic value of your waste stream.