Biomass Electricity Generation for Beverage Wastewater Management

The global beverage industry, spanning breweries, distilleries, soft drink manufacturers, and fruit juice processors, is characterized by high production volumes and high operational energy demands. A significant consequence of this productivity is the generation of voluminous wastewater, rich in organic loads like sugars, alcohol, proteins, and yeast. This effluent, while posing a major challenge for disposal, is in fact a highly valuable, untapped energy resource.

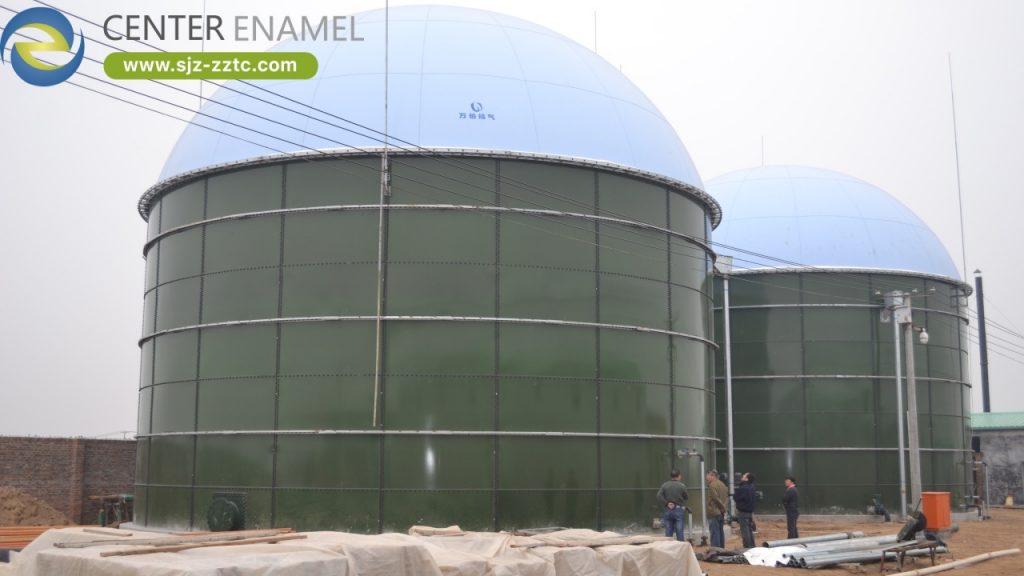

The transition from a linear waste disposal model to a circular, energy-positive system is now mandatory for corporate social responsibility and cost efficiency. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) is the crucial infrastructure partner enabling this shift through advanced Biomass Electricity Generation integrated within Beverage Wastewater Management. We provide the containment foundation for high-rate anaerobic digestion, effectively converting the effluent’s concentrated Chemical Oxygen Demand (COD) into reliable, on-site methane-rich biogas.

By housing these essential anaerobic systems in our durable and chemically inert Glass-Fused-to-Steel (GFS) tanks, Center Enamel offers a robust, compact, and energy-efficient solution. This strategy allows beverage producers to achieve superior environmental compliance and secure long-term energy independence, fundamentally transforming their wastewater liability into a powerful asset.

The Specialized Demands of Beverage Effluent

Beverage Wastewater Management requires technical expertise tailored to the unique composition and flow characteristics of the industry’s effluent streams.

1. High Organic Concentration and Suitability for Biogas

Beverage wastewater possesses an ideal composition for Biomass Electricity Generation:

Elevated Chemical Oxygen Demand (COD): Effluent from fermentation and cleaning processes (especially from breweries and distilleries) contains vast amounts of readily biodegradable organic matter. This high COD concentration is the driving force behind the economic viability of anaerobic digestion, offering maximum fuel yield for subsequent power generation.

Acidity and High Temperature: Wastewater is often discharged at high temperatures and may be acidic due to process chemicals (e.g., caustic cleaning solutions) or fermentation byproducts. The treatment system must be able to manage rapid acidity level changes and thermal variations while maintaining a stable, high-performance microbial environment.

Variable Loading: Production in the beverage industry is often cyclical or seasonal. The wastewater management system must possess the resilience and hydraulic capacity to handle significant fluctuations in both flow volume and organic load without negatively impacting the stability of biogas production.

2. Strategic Operational and Environmental Benefits

Implementing Biomass Electricity Generation solves core business challenges for beverage producers:

Energy Cost Mitigation: The beverage industry is energy-intensive, requiring substantial power for chilling, bottling, sterilization, and general operations. Generating power directly from wastewater significantly lowers reliance on the commercial grid, insulating the facility from volatile utility prices and providing a predictable, low-cost internal energy source.

Environmental Stewardship: Consumer demand for sustainable practices is high. Capturing methane, a potent greenhouse gas that would otherwise escape from uncontrolled waste, and using it to generate Biomass Electricity Generation dramatically reduces the mill’s carbon footprint, reinforcing the brand’s commitment to environmental responsibility.

Odor and Compliance Control: Enclosed anaerobic digesters eliminate the odors associated with the decay of high-organic wastewater. More importantly, they achieve a massive reduction in the COD load (often 80-95%), drastically simplifying the final purification steps required for discharge compliance.

Technology at the Core: High-Rate Anaerobic Digestion

The most effective approach in Beverage Wastewater Management is the use of high-rate anaerobic reactors, such as the Upflow Anaerobic Sludge Blanket (UASB) or the Expanded Granular Sludge Bed (EGSB). These systems are specifically designed to handle high flows and high organic concentrations common in this industry.

1. The Power Generation Cycle

The conversion of beverage effluent into electrical power is a highly efficient, two-step process:

Efficient Methane Production: Within the high-rate reactor, microorganisms in the dense granular sludge bed rapidly consume the organic load. The end result is the production of methane-rich biogas at exceptionally high rates, thanks to the inherent biodegradability of sugars and starches in beverage waste.

Biomass Electricity Generation: The recovered and purified biogas is fed into a Combined Heat and Power (CHP) unit or a dedicated engine. The combustion process generates electricity, which powers the beverage plant’s operations, while simultaneously recovering thermal energy. This recovered heat is then recycled for use in pasteurization, bottle washing, or maintaining the digester's optimal operating temperature, achieving an overall system efficiency that minimizes energy waste.

Compact Footprint: Unlike traditional lagoons, high-rate anaerobic reactors are compact, vertical structures that process massive volumes of wastewater in a small area. This design minimizes the physical footprint, a critical advantage for urban or land-constrained bottling and brewing facilities.

2. Maximizing Value Beyond Power

The benefits of anaerobic digestion extend beyond Biomass Electricity Generation:

Nutrient-Rich Digestate: The stabilized, low-odor liquid effluent (digestate) retains essential plant nutrients. This can be repurposed as a valuable soil amendment, completing the circular economy model by returning nutrients to agricultural land used for growing the raw materials (like barley, hops, or fruit).

Reduced Sludge Output: Anaerobic treatment naturally produces far less waste biological sludge than conventional aerobic processes, significantly reducing the costs and logistics associated with final sludge disposal.

Pre-treatment Performance: The substantial COD reduction achieved in the anaerobic step significantly lowers the hydraulic and organic load entering subsequent aerobic treatment stages, reducing the required size, energy demand, and chemical consumption of the overall Beverage Wastewater Management system.

GFS Tanks: Unyielding Containment for Biogas Infrastructure

The success and longevity of any Biomass Electricity Generation project hinge on the integrity of the reactor vessel. For the demanding conditions of Beverage Wastewater Management—involving fluctuating temperatures, moderate acidity, and continuous gas pressure—structural reliability and chemical resistance are paramount. Center Enamel’s Glass-Fused-to-Steel (GFS) tanks provide the ultimate proven solution.

Uncompromising Integrity and Resistance

GFS technology is specifically engineered to provide a robust, long-term barrier against the beverage effluent environment:

Ultimate Corrosion Resistance: The anaerobic digestion of beverage waste, especially brewing effluent, produces a corrosive environment rich in hydrogen sulfide and organic acids. The GFS coating, a molecularly fused, inert glass layer on high-strength steel, creates an impervious, non-porous chemical barrier. This protection guarantees the tank's operational life extends over decades without the costly corrosion and maintenance required by conventional coatings or materials.

Structural Reliability: GFS tanks are built using high-strength steel panels, engineered to withstand the immense hydrostatic load, weight of dense sludge, and dynamic forces exerted by powerful internal mixing systems required in high-rate anaerobic reactors.

Guaranteed Gas-Tightness: The safe and efficient capture of methane is the foundation of Biomass Electricity Generation. The modular, bolted GFS design utilizes specialized, durable sealants and precision fitting to ensure a superior, permanent gas-tight seal. This maximizes the recovery of the methane fuel and is essential for safety, odor control, and strict compliance.

Operational and Economic Advantages

Choosing GFS provides strategic advantages that streamline project execution and lifetime costs:

Rapid, Consistent Installation: GFS components are factory-finished and rapidly assembled on-site, regardless of weather conditions. This significantly accelerates construction timelines compared to traditional concrete, allowing the Beverage Wastewater Management system to start generating power and revenue much faster.

Scalability and Flexibility: The modular GFS design allows for easy capacity expansion as production at the beverage plant grows, providing flexibility that fixed concrete structures cannot match.

Low Lifetime Maintenance: The smooth, inert glass surface naturally resists the growth of scaling, biofilm, and residue buildup, minimizing the need for internal inspection, cleaning, and major maintenance over its long operational life.

Project Cases

Center Enamel is a trusted global provider of large-scale GFS containment for the industrial and beverage sectors, enabling high-efficiency anaerobic digestion and successful Biomass Electricity Generation in challenging Beverage Wastewater Management scenarios.

Zhejiang Shaoxing Chemical Wastewater Treatment Project: This project involved providing GFS containment for treating a large volume of complex chemical wastewater, demonstrating our capacity to manage high-load, continuous flow environments analogous to large-scale beverage or fermentation effluent. The installation consisted of 2 units with a total capacity of 11,609 cubic meters, showcasing our ability to deliver substantial high-capacity containment solutions.

Budweiser Beer Group Mozambique Brewery Wastewater Treatment Project: We supplied GFS containment directly to a major international brewery, highlighting our expertise in the Beverage Wastewater Management sector. This installation involved 11 units with a total capacity of 9,437 cubic meters, affirming our capability to execute complex, multi-unit projects for world-leading beverage corporations requiring reliable Biomass Electricity Generation infrastructure.

Hainan Food Wastewater Treatment Project: We provided robust GFS containment for a large-scale food and beverage wastewater initiative. This project consisted of 2 units with a total capacity of 6,714 cubic meters, further cementing our proven track record in supplying foundational infrastructure for high-volume organic waste applications demanding consistent biogas recovery and structural longevity.

Conclusion: Securing the Future of Beverage Production

The integration of Biomass Electricity Generation into Beverage Wastewater Management is the defining feature of a modern, sustainable beverage facility. It transforms the challenging high COD effluent into a reliable, self-generated power source, addressing the core needs of cost control, energy security, and environmental stewardship.

By partnering with Center Enamel and deploying our industry-leading Glass-Fused-to-Steel (GFS) tanks, beverage producers secure a foundation of unmatched durability and chemical resistance. This robust infrastructure is the key to efficient anaerobic digestion, ensuring maximized methane recovery, long-term energy independence, and comprehensive compliance, turning effective Beverage Wastewater Management into a powerful, profitable, and sustainable business advantage.