China Biogas Digester Manufacturer

In the strategic energy landscape of two thousand twenty six, the Biogas Digester has evolved from a simple waste containment vessel into a sophisticated biological refinery. As the global community moves toward deep decarbonization and localized energy security, the ability to convert organic waste—ranging from agricultural residues and food waste to municipal sludge—into stable, renewable methane has become an industrial gold standard. For project developers and municipal planners, the success of these vital infrastructure assets rests on the reliability of the containment hardware and the sophistication of the process engineering.

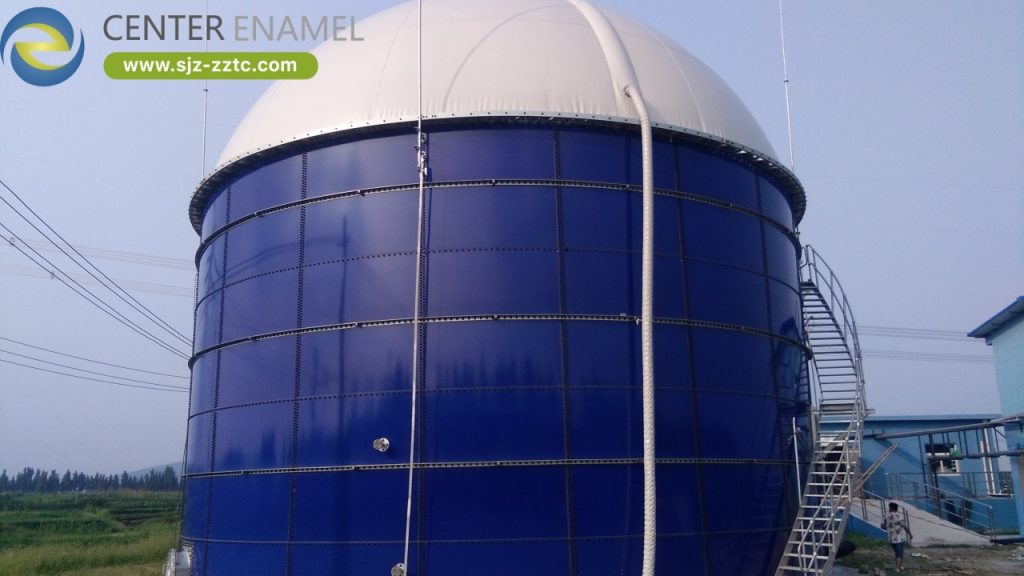

Shijiazhuang Zhengzhong Technology Co., Ltd, operating under the world-renowned brand Center Enamel, stands as the preeminent China Biogas Digester Manufacturer. With a history of innovation spanning over thirty years and a project portfolio reaching across more than one hundred countries, we provide the essential EPC (Engineering, Procurement, and Construction) expertise required to build high-performance digestion facilities. Our competitive advantage lies in our mastery of Glass Fused to Steel (GFS) reactors, high-performance Epoxy Coated Tanks, and integrated gas-to-power systems, designed to ensure maximum uptime and energy conversion efficiency.

Technical Foundations: The Biological Heart of the Biogas Digester

To function as a reliable "industrial stomach," a Biogas Digester must maintain a perfectly balanced environment for specialized microorganisms. As a leading China Biogas Digester Manufacturer, Center Enamel focuses on the synchronization of biological and mechanical systems to maximize gas yield.

1. The Four-Stage Anaerobic Digestion Sequence

Our digesters are engineered to support the complex microbial sequence required for organic breakdown:

Hydrolysis: Converting complex organic polymers (proteins, fats, and carbohydrates) into soluble monomers.

Acidogenesis: Fermenting these monomers into volatile fatty acids and alcohols.

Acetogenesis: Breaking down these intermediates into acetic acid, hydrogen, and carbon dioxide.

Methanogenesis: The final and most sensitive stage, where methanogens convert these products into methane-rich biogas.

2. CSTR Technology: The Pinnacle of Digestion Efficiency

Center Enamel specializes in the CSTR (Continuous Stirred Tank Reactor) process. This technology is particularly effective for diverse feedstocks, as it maintains a uniform temperature and substrate distribution through mechanical agitation. This prevents the formation of scum layers and dead zones, ensuring that the Biogas Digester operates at peak biological efficiency.

Core Hardware: Engineering Resilience for Energy Production

The harsh chemical environment inside a Biogas Digester requires materials that can withstand aggressive corrosion from organic acids and gaseous byproducts. Center Enamel’s hardware solutions are engineered for these specific industrial rigors.

1. Glass Fused to Steel (GFS) Tanks

Our flagship GFS tanks are the global benchmark for anaerobic reactors. By fusing high-tech glass enamel to specialized steel at temperatures exceeding eight hundred twenty degrees Celsius, we create a surface that is chemically inert and structurally robust. This technology is critical for digesters, where hydrogen sulfide would quickly degrade standard steel or concrete alternatives.

2. Epoxy Coated Tanks: Specialized Process Support

As a critical part of our infrastructure portfolio, Center Enamel Epoxy Coated Tanks provide an excellent solution for various auxiliary stages within the treatment train.

Advanced Coating Technology: Our epoxy tanks utilize a high-specification electrostatic powder coating process. This results in a smooth, durable finish that provides excellent resistance against a wide range of industrial chemicals and organic residues.

Versatile Application: These tanks are ideal for equalization, storage of treated digestate, or as buffer tanks for incoming feedstock. They offer a cost-effective yet highly durable alternative where high corrosion resistance is essential, ensuring the entire facility maintains a consistent standard of quality.

Factory-Controlled Precision: Every tank is manufactured under strict conditions to ensure consistent coating thickness and superior bond strength, providing a reliable long-term storage solution for aggressive environments.

3. Double Membrane Roof: Dynamic Gas Storage

In any high-efficiency Biogas Digester project, capturing and storing the produced gas is vital.

Dynamic Storage: Our Double Membrane Roof systems feature an inner gas-holding membrane and a pressurized outer protective membrane. This ensures zero methane leakage while regulating internal pressure.

Integrated Gas Holder: The flexible inner membrane expands and contracts based on gas volume, acting as a buffer that ensures a steady flow to downstream utilization systems like CHP units.

4. Aluminum Dome Roofs: Maintenance-Free Protection

For the storage of treated digestate or process water where gas capture is not the primary requirement, Center Enamel provides specialized Aluminum Dome Roofs .

Corrosion Resistance: Constructed from high-strength aluminum alloy, these roofs are naturally resistant to the humid atmosphere of a treatment plant.

Structural Efficiency: The geodesic design allows for wide spans without internal columns, ensuring that internal mixing and pumping equipment can operate without obstruction.

Comprehensive System Integration: The EPC Advantage

Beyond providing world-class containment vessels, Center Enamel excels as a China Biogas Digester Manufacturer by offering integrated process engineering.

1. Advanced Mixing and Agitation Solutions

To prevent sedimentation and ensure optimal microbial contact, we integrate high-efficiency mixing systems. These are designed to maintain a homogeneous environment within our Epoxy Coated Tanks and GFS reactors, preventing the formation of dead zones and maximizing methane yields.

2. Precision Thermal Management

Anaerobic microorganisms are highly sensitive to temperature. Our EPC services ensure that every Biogas Digester is equipped with precise insulation and heating systems, often utilizing waste heat from power generation to maintain optimal mesophilic or thermophilic conditions.

Global Project Excellence: Center Enamel Project Cases

Our standing as a premier China Biogas Digester Manufacturer is validated by a proven track record of successful installations across diverse sectors:

Shandong Heze Biogas Project This major initiative utilized 3 units of our high-performance GFS tanks. The project successfully transforms concentrated organic residues into a stable energy stream, demonstrating the reliability of our integrated storage and digestion systems.

Inner Mongolia Hinggan League Bio-Natural Gas Project In a region characterized by extreme temperature fluctuations, this installation integrated 4 units of our bolted steel tanks. These vessels and their Double Membrane Roofs provide the stable environment necessary for the high-efficiency production of bio-natural gas from agricultural waste.

Jiangsu Xuzhou Biogas Project This project involved the deployment of 4 units of our advanced containment technology. It serves as a model for how professional EPC services can be used to rapidly build the essential infrastructure needed for industrial energy recovery from diverse waste sources.

Why Partner with Center Enamel?

Choosing Center Enamel as your China Biogas Digester Manufacturer provides several strategic advantages:

International Standards: Our tanks and equipment meet globally recognized standards, including AWWA D103-09, ISO 28765, and NSF ANSI 61.

Rapid Deployment: The modular bolted design allows for fast on-site assembly, significantly reducing construction timelines compared to traditional concrete.

Technical Acumen: With over twenty patents in enameling technology and a dedicated R&D team, we offer unmatched expertise in material science and process engineering.

Global Support: With projects in over one hundred countries, we provide comprehensive technical and after-sales support to ensure long-term operational success.

Engineering the Future of Sustainable Energy

The successful execution of a renewable energy strategy relies on the reliability, efficiency, and modularity of the Biogas Digester infrastructure used. By selecting a specialized China Biogas Digester Manufacturer like Center Enamel, organizations secure a foundation of certified, modular, and durable infrastructure.

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are dedicated to providing the innovation and engineering excellence that make these projects a success. From our premier GFS tanks and high-performance Epoxy Coated Tanks to our specialized Double Membrane Roofs and Aluminum Dome Roofs, we offer a total containment solution designed for the future of industrial sustainability. Our commitment to quality ensures that every project we undertake is built to perform and engineered to last.