China Biogas Membrane Manufacturer

The success of modern biogas facilities—from small decentralized plants to large industrial anaerobic digestion complexes—is contingent upon two key factors: the structural integrity of the digester and the efficiency of gas storage. The Biogas membrane system is the critical element that transforms the digester from a waste treatment vessel into a high-performance energy asset. A high-quality Biogas membrane is essential for securely capturing methane, regulating pressure, and ensuring system safety.

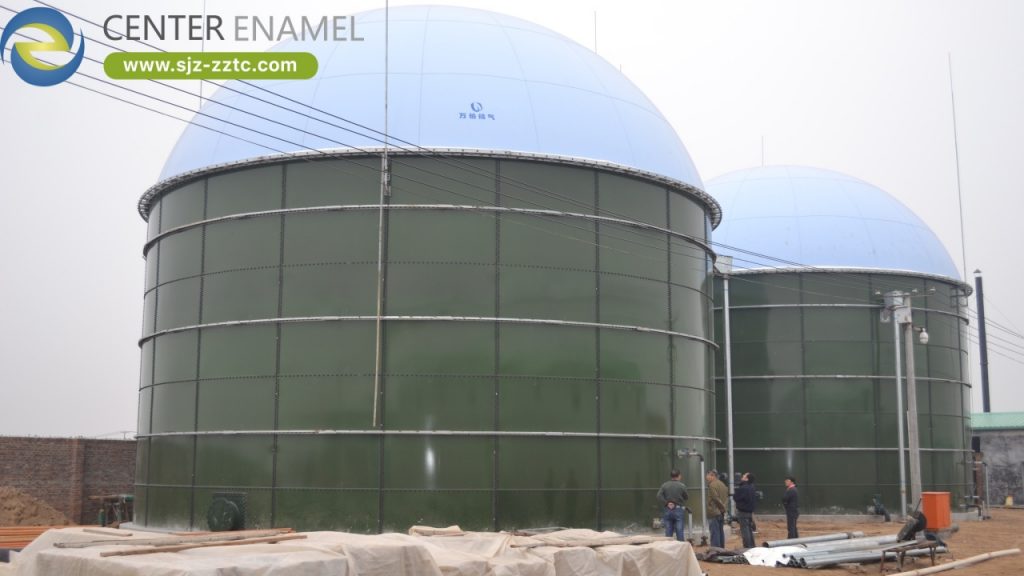

Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) is globally recognized as a leading China Biogas membrane manufacturer, specializing in the design, engineering, and supply of integrated containment systems. Our core product is the highly durable Glass-Fused-to-Steel (GFS) tank, which serves as the foundational structure. Crucially, we are experts in the manufacture of the Double Membrane Roof—a comprehensive system utilizing advanced Biogas membrane material—which provides the ultimate solution for gas storage atop our digester tanks.

By seamlessly integrating superior containment (GFS) with high-performance gas holding technology (our Biogas membrane roof), Center Enamel ensures maximum gas capture efficiency, structural resilience, and long-term operational savings. We are committed to driving the global adoption of renewable energy by delivering reliable, customized, and industry-leading Biogas membrane solutions.

Center Enamel’s Leadership as a China Biogas Membrane Manufacturer

While the biogas membrane industry includes suppliers of basic material films, Center Enamel’s leadership is defined by the manufacture and integration of the complete Double Membrane Roof system, which is the most widely adopted Biogas membrane storage technology worldwide.

1. The Double Membrane Roof: Our Biogas Membrane Solution

The Biogas membrane roof system, manufactured by Center Enamel, is designed to serve two vital functions simultaneously: safely containing the biogas and stabilizing the pressure within the digester.

Dual-Layer Security: The system features an outer membrane for structural protection against wind, snow, and UV radiation, and an inner membrane that dynamically stores the biogas. The space between the two is pressurized with air, maintaining the structural stability of the dome and regulating the pressure of the stored biogas.

Superior Material Science: The membrane material used in our Biogas membrane roofs is a high-strength, specially treated polyester fabric coated with a polymer (like PVC or similar durable material). This material is resistant to fungi, ultraviolet rays, and, critically, the chemical corrosion caused by hydrogen sulfide and other components found in raw biogas.

Seamless Integration with GFS: As a vertically integrated supplier, Center Enamel engineers the Biogas membrane roof mounting hardware to perfectly interface with our GFS tank top rings, guaranteeing an airtight seal and structural security, which is often a point of failure for third-party systems.

2. GFS Containment: The Foundation for the Biogas Membrane

The longevity of the Biogas membrane system depends on the stability of the structure it rests upon. Our GFS tanks provide that stable, corrosion-proof foundation:

Corrosion Resistance: The primary digester vessel must withstand the highly acidic and corrosive environment. The inert glass layer fused to the steel eliminates internal corrosion risk, ensuring the Biogas membrane system's supporting structure remains intact for a multi-decade service life.

Structural Stability: GFS tanks are engineered to handle the loads imposed by heavy mixing equipment and the varying pressure stresses transmitted by the Biogas membrane system (both positive storage pressure and negative pressure swings).

Technical Excellence and Integrated System Design

Center Enamel's value proposition is the seamless delivery of a unified, high-performance biogas system where every component, particularly the Biogas membrane and its containment, is optimized for peak efficiency.

1. Maximizing Methane Capture

The primary purpose of the Biogas membrane roof is to ensure that virtually zero methane escapes into the atmosphere.

Gas-Tight Guarantee: The double-membrane structure and engineered sealing profile achieve exceptional gas-tightness. This maximizes the volume of biogas available for utilization (heating, power generation, or upgrading), directly increasing the project's energy output and financial return.

Pressure Regulation: The air-cushioned design of the Biogas membrane roof stabilizes the pressure, providing a steady flow of gas to downstream equipment. This is essential for the reliable operation of CHP units and upgrading technology, preventing costly system interruptions.

2. Diversified Containment for the Complete Biogas Loop

Beyond the core digester and its Biogas membrane roof, a successful biogas plant requires containment for pre-treatment, post-digestion, and water management. Center Enamel supplies tailored solutions using various materials:

Epoxy Coated Steel Tanks: Used for supporting roles such as raw water storage, equalization basins, or effluent handling where cost-efficiency and durability are balanced against corrosive severity.

Stainless Steel Tanks: Specified for critical process stages requiring the highest non-reactivity, such as specialized feed storage or final product storage, ensuring material quality is maintained.

3. Protecting Auxiliary Resources with Aluminum Dome Roofs

While the Biogas membrane roof protects the gas, the Aluminum Dome Roof protects valuable liquid resources in auxiliary tanks:

Digestive Protection: Used over final digestate or treated water storage tanks, the Aluminum Dome Roof provides a permanent, maintenance-free, non-corrosive cover. This prevents external contamination and preserves the quality of the valuable bio-fertilizer product.

Longevity and Low Maintenance: The aluminum construction resists corrosion and eliminates the need for repainting or frequent repair, reducing long-term operational expenditure across the entire biogas site.

Economic, Environmental, and Global Impact

As a premier China Biogas membrane manufacturer, Center Enamel’s integrated solutions deliver profound economic and environmental benefits, supporting the global transition to sustainable energy.

1. Enhanced Investment Return (ROI)

The durability and efficiency of Center Enamel’s systems ensure maximum return on investment:

Operational Longevity: The combination of the 30-year-plus service life of the GFS tank and the robust design of the Biogas membrane roof minimizes system failures, maximizing uptime and production capacity.

Reduced Operating Costs: The low-maintenance design of both the GFS tank and the Biogas membrane roof reduces labor, materials, and downtime costs associated with conventional containment.

2. Environmental and Regulatory Compliance

The effective Biogas membrane system is key to environmental stewardship:

Methane Mitigation: Secure gas capture by the Biogas membrane roof directly reduces atmospheric methane emissions—a crucial action in combating climate change and adhering to global environmental protocols.

Odor Control: The gas-tight seal of the Biogas membrane roof prevents odors from escaping the digester, improving community relations and site hygiene.

3. Global Market Reach and Customization

Center Enamel has successfully deployed its Biogas membrane and GFS solutions in over one hundred countries, demonstrating our capability to meet varied international demands:

Climatic Adaptability: Our Biogas membrane roofs are designed to withstand diverse climate conditions, including heavy snow loads, high winds, and extreme UV exposure, ensuring reliable performance whether in the tropics or in harsh northern latitudes.

Modular and Scalable: The modular nature of our GFS tanks and Biogas membrane systems allows for easy customization to fit any project size—from small agricultural installations to large municipal waste treatment plants—and allows for future expansion.

Project Cases: Center Enamel’s Biogas Membrane Integration Excellence

The following non-fictitious projects from our biogas portfolio highlight the successful deployment and critical role of Center Enamel’s GFS tanks and integrated Biogas membrane solutions in large-scale, high-performance energy facilities.

Jiangsu Xuzhou Biogas Project: This major energy-from-waste initiative required 4 units of high-capacity GFS containment. The reliable, high-volume gas production demanded by this project was secured by our integrated Biogas membrane roof systems, maximizing the facility's output. The installation utilized 4 units with a substantial total capacity.

Inner Mongolia Hinggan League Bio-Natural Gas Project: This significant bio-natural gas upgrading project involved 4 units of GFS tanks. The successful upgrading process relies entirely on the quality and stability of the raw biogas supply, which is directly managed and protected by our advanced Biogas membrane technology. The installation utilized 4 units with a substantial total capacity.

Sweden Biogas Project: This international project involved 1 unit of GFS containment, adhering to the stringent European standards for gas safety and environmental performance. The integration of our certified Biogas membrane solution was crucial for meeting local regulations regarding gas leakage and structural integrity. The installation utilized 1 unit with a substantial total capacity.

Choosing the Definitive China Biogas Membrane Manufacturer

For investors, developers, and operators of biogas facilities worldwide, the longevity and profitability of the asset depend on choosing a partner who excels at both containment and gas management. Center Enamel stands as the definitive China Biogas membrane manufacturer because we provide the integrated solution.

By choosing Center Enamel, you secure:

The decades-long structural integrity of the GFS core.

The advanced gas capture and pressure regulation provided by our Double Membrane Roof (Biogas membrane) systems.

The comprehensive resource protection delivered by our Aluminum Dome Roofs for auxiliary vessels.

Partner with Center Enamel to leverage the world's most durable and efficient Biogas membrane containment technology, ensuring your sustainable energy project achieves maximum efficiency, safety, and return on investment.