China Commercial Biogas Digester Manufacturer

The transition toward a circular economy and sustainable energy production has made the Commercial Biogas Digester a pivotal infrastructure asset. Unlike smaller, localized systems, the commercial-scale digester is a high-capacity, intensive facility designed to maximize energy output and resource recovery from substantial volumes of organic feedstocks, including agricultural waste, food processing residues, and municipal sludge. For operators of these critical energy facilities, choosing a China Commercial Biogas Digester Manufacturer that guarantees long-term durability and operational efficiency is paramount.

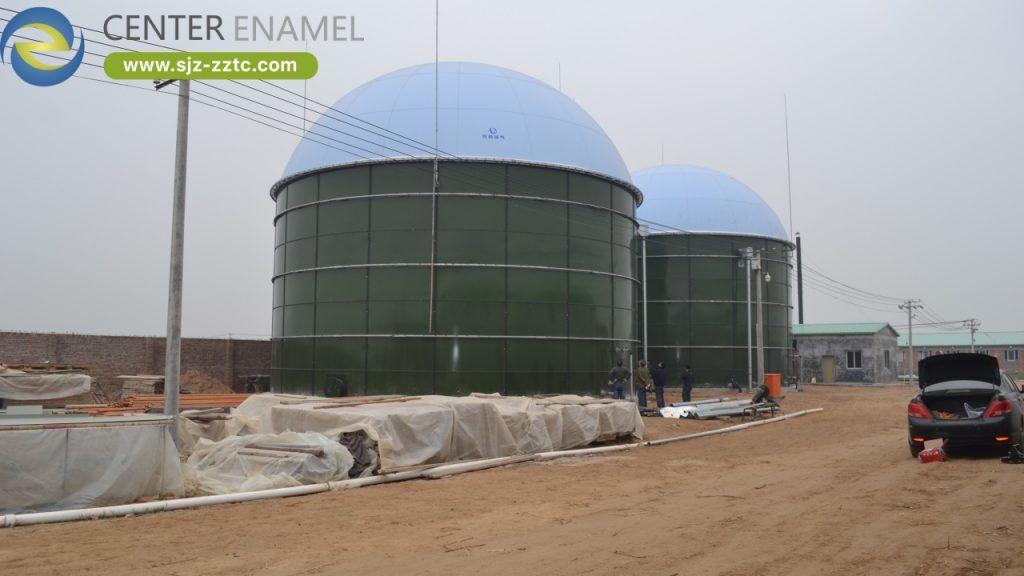

Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) is globally recognized as the leading China Commercial Biogas Digester Manufacturer. We specialize in designing, engineering, and producing high-performance, modular containment solutions optimized for the demanding environment of commercial anaerobic digestion. Our core product, the Glass-Fused-to-Steel (GFS) tank, is the foundation of our Commercial Biogas Digester systems, offering unparalleled corrosion resistance, structural integrity, and rapid installation capability.

Our commitment extends to delivering a complete, integrated system—from the primary digester vessel and gas holder to specialized auxiliary tanks. By focusing on superior material science and adherence to global engineering standards, Center Enamel ensures that every Commercial Biogas Digester asset delivered is reliable, efficient, and ready to meet the financial and environmental performance goals of our global clients.

Center Enamel’s Leadership as a China Commercial Biogas Digester Manufacturer

The commercial biogas sector demands solutions that are robust enough to withstand continuous, high-load operation and corrosive conditions. Center Enamel's position among China Commercial Biogas Digester Manufacturers is secured by our dedication to quality, scale, and international project execution.

1. GFS Technology: The Core of the Commercial Biogas Digester

The aggressive, corrosive atmosphere within a Commercial Biogas Digester (caused by organic acids and sulfur compounds) necessitates a containment solution built for decades of service.

Superior Corrosion Resilience: Our Glass-Fused-to-Steel technology is an industry benchmark. The inert glass layer, fused to the steel shell at high temperatures, creates an impermeable, chemical-resistant barrier. This ensures the structural integrity of the Commercial Biogas Digester is maintained against the acidic and corrosive contents, far surpassing the life expectancy of standard concrete or epoxy-lined tanks.

High Structural Strength: GFS is engineered for commercial scale. The bolted steel structure is capable of containing massive volumes and enduring the dynamic stresses imposed by heavy mixers and continuous material flow, which are common features of any Commercial Biogas Digester.

Global Standard Compliance: Our manufacturing processes and Commercial Biogas Digester designs are certified to meet major international standards, ensuring seamless project approval and integration worldwide.

2. Cost Efficiency and Rapid Deployment

For commercial projects, time and total cost of ownership are critical factors. Center Enamel provides significant advantages over conventional construction methods:

Modular Advantage: As a modular bolted system, our Commercial Biogas Digester components are fabricated off-site, ensuring quality control and eliminating weather-related construction delays.

Minimized Downtime: The rapid erection process dramatically shortens the project timeline, allowing the commercial facility to begin generating revenue and recovering capital investment sooner.

Integrated Commercial Biogas Digester Equipment and Containment

A high-performance Commercial Biogas Digester system requires specialized containment for every process step—from pre-treatment to gas recovery and digestate storage. Center Enamel ensures an optimized solution by deploying a combination of high-grade materials.

1. Gas Management with Double Membrane Roofs

Maximizing the capture and secure storage of biogas is essential for the commercial viability of the digester. The Double Membrane Roof is the premium choice supplied by Center Enamel:

Secure Methane Storage: Integrated atop the GFS Commercial Biogas Digester, this specialized roofing system provides a flexible, gas-tight volume for the safe, low-pressure storage of methane, ensuring a stable, regulated fuel supply for CHP (Combined Heat and Power) units or gas-to-grid systems.

Corrosion Protection and Safety: The lightweight design eliminates the corrosion risks associated with traditional metal roofs while ensuring a superior seal to prevent fugitive gas emissions and maintain site safety.

2. Diversified Containment Solutions

To optimize project resilience and cost, we utilize a materials palette tailored to specific functional needs within the commercial plant:

Epoxy Coated Steel Tanks: Used for supporting, less corrosive processes such as general water storage, fire suppression, or low-concentration effluent equalization, offering an economical and durable solution.

Stainless Steel Tanks: Specified for critical tasks requiring the highest degree of purity and non-reactivity, such as storing final, high-value liquid bio-fertilizer products or process chemicals, ensuring product quality and safety.

3. Protecting Resources with Aluminum Dome Roofs

In commercial operations, protecting the asset and minimizing environmental impact is vital. The Aluminum Dome Roof provides a solution for auxiliary containment:

Digestive Protection: Used over final digestate or treated water storage tanks, the Aluminum Dome Roof offers a permanent, non-corrosive barrier against external contamination (rain, dust, debris). This preserves the quality of the valuable fertilizer or recycled water product.

Maintenance-Free Longevity: Constructed from corrosion-resistant aluminum, the dome requires minimal maintenance over its long service life, reducing operational costs for the Commercial Biogas Digester facility.

Economic and Environmental Benefits of Commercial Biogas Digester Technology

Investing in a robust Commercial Biogas Digester from a top China Commercial Biogas Digester Manufacturer yields direct returns in energy independence, waste compliance, and product sales.

1. High-Value Energy Generation

The commercial-scale operation generates significant quantities of biogas, which can be monetized in several ways:

On-Site Power: Biogas fuels CHP units, providing cost-effective electricity and heat for the host facility (e.g., farm, factory, or municipal plant).

Grid Injection: Upgrading biogas to bio-natural gas allows for injection into the national gas grid, creating a stable, long-term revenue stream.

2. Sustainable Resource Recovery

The Commercial Biogas Digester transforms waste liabilities into valuable, marketable resources:

Odor and Pathogen Reduction: Anaerobic digestion significantly reduces pathogen count and eliminates most nuisance odors, simplifying compliance and community relations.

Bio-Fertilizer Production: The resulting digestate is an odorless, nutrient-rich soil amendment (bio-fertilizer), which is highly stable and readily usable by local agriculture, displacing chemical fertilizers

3. Operational Certainty

The longevity and reliability of the Commercial Biogas Digester containment are key to continuous operation:

Minimizing Downtime: By utilizing highly durable GFS technology, the risk of containment failure, leaks, or required surface repairs is minimized, ensuring the Commercial Biogas Digester operates with maximum uptime.

Optimized footprint: The vertical GFS design allows for high-volume storage in a smaller physical footprint compared to conventional pits or ponds, maximizing valuable commercial land use.

Project Cases: Center Enamel’s Commercial Biogas Digester Excellence

Center Enamel's portfolio showcases our ability to deliver large-scale, high-performance Commercial Biogas Digester solutions to varied industries and international markets, confirming our leadership among China Commercial Biogas Digester Manufacturers.

The following non-fictitious cases, directly sourced from our accurate project portfolio, highlight the successful deployment of our GFS-based biogas systems:

Hebei Cangzhou Biogas Project: This large-scale commercial biogas project required the successful deployment of 2 units of high-capacity digester vessels. The size and capacity of this installation confirms our expertise in delivering robust, regional Commercial Biogas Digester infrastructure for centralized organic waste and energy generation. The installation utilized 2 units with a substantial total capacity.

France Biogas Project: This significant international installation involved the integration of 1 unit of GFS containment into a European-based commercial energy facility. This project demonstrates the adaptability and certification of our Commercial Biogas Digester solutions in meeting stringent European performance, quality, and environmental standards. The installation utilized 1 unit with a substantial total capacity.

Slurry Storage Emergency Tank Project: This large commercial project required the deployment of 1 unit of high-volume GFS containment dedicated to emergency slurry storage, a critical component of any large-scale Commercial Biogas Digester facility. This case highlights our ability to provide essential, high-integrity auxiliary tanks designed to manage high-solids agricultural and industrial feedstocks safely. The installation utilized 1 unit with a substantial total capacity.

Partnering with the Top China Commercial Biogas Digester Manufacturer

The commercial success of a biogas facility relies fundamentally on the integrity and durability of its core equipment. For investors, project developers, and operators worldwide, choosing a China Commercial Biogas Digester Manufacturer with a proven record of material excellence and global execution is the most critical decision.

Center Enamel offers the definitive advantage:

Unmatched Durability: The GFS Commercial Biogas Digester provides lifelong resistance to the corrosive process environment.

Integrated Resource Systems: Seamless inclusion of Double Membrane Roofs for biogas security and Aluminum Dome Roofs for long-term resource protection.

Commercial Certainty: The assurance of working with a certified, globally experienced China Commercial Biogas Digester Manufacturer dedicated to maximizing your energy and environmental return.

Partner with Center Enamel to invest in a reliable, high-performance Commercial Biogas Digester asset that secures your sustainable energy future.