China Pig Farm Wastewater Treatment Processes Contractor

In the strategic environmental landscape of 2026, the global livestock industry is undergoing a paradigm shift. Pig farming, while essential for food security, presents one of the most significant environmental challenges due to the massive volume of high-strength organic effluent it generates. Pig farm wastewater is characterized by extreme concentrations of organic matter, ammonia-nitrogen, and suspended solids. To manage these loads effectively, farmers and agricultural enterprises require more than just equipment—they need a specialized China Pig Farm Wastewater Treatment Processes Contractor capable of delivering integrated "waste-to-energy" solutions.

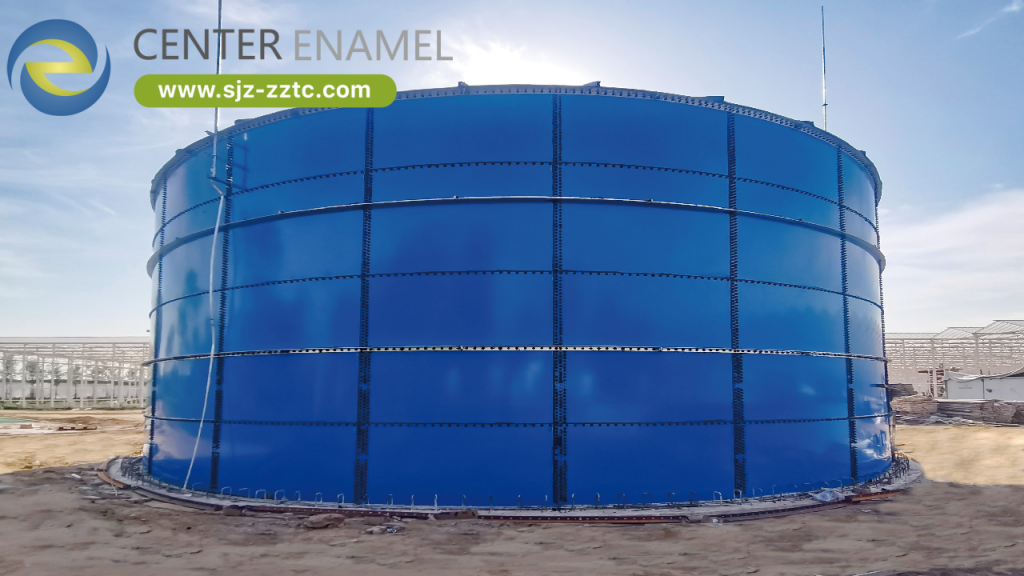

Shijiazhuang Zhengzhong Technology Co., Ltd, operating under the world-renowned brand Center Enamel, stands at the forefront of this evolution. With over thirty years of innovation and a project footprint spanning more than one hundred countries, we provide the turnkey EPC (Engineering, Procurement, and Construction) expertise required to master complex Pig Farm Wastewater Treatment Processes. Our core advantage lies in our proprietary Glass-Fused-to-Steel (GFS) reactors, high-performance Epoxy Coated Tanks, and advanced anaerobic technologies designed to maximize biogas recovery and environmental compliance.

Technical Foundations: The Biological Engine of Modern Piggeries

Effective Pig Farm Wastewater Treatment Processes must address the "hostile" nature of manure, which is rich in undigested feed, fibers, and high levels of ammonia that can inhibit standard biological activity.

1. The Multi-Stage Treatment Sequence

Our agricultural systems follow a rigorous sequence optimized for 2026 sustainability standards:

Pre-treatment & Solid-Liquid Separation: Utilizing mechanical separators to remove fibrous solids. This critical first step protects downstream reactors from clogging and reduces the organic load by a significant margin.

Anaerobic Digestion (The Energy Heart): High-concentration pig manure is fed into anaerobic reactors—most commonly the CSTR (Continuous Stirred Tank Reactor) or USR (Upflow Sludge Reactor). These processes degrade complex organic pollutants while capturing valuable biogas.

Aerobic Polishing: Following anaerobic stabilization, aerobic processes like SBR (Sequencing Batch Reactor) or A/O (Anoxic/Oxic) units are used to further reduce nitrogen levels and achieve discharge-quality effluent.

2. Ammonia Management and Nutrient Recovery

Pig urine is notoriously high in nitrogen. As a premier China Pig Farm Wastewater Treatment Processes Contractor, Center Enamel integrates specialized ammonia-stripping or nitrification-denitrification stages. This prevents the eutrophication of local water bodies and allows for the recovery of nutrients to be used as liquid bio-fertilizer.

Core Hardware: Engineering Resilience for Agricultural Infrastructure

The success of Pig Farm Wastewater Treatment Processes depends on the durability of the containment vessels. The aggressive chemical environment of manure, characterized by organic acids and hydrogen sulfide, requires specialized materials.

1. Glass-Fused-to-Steel (GFS) Tanks

Our flagship GFS tanks are the global benchmark for pig farm anaerobic digesters. By fusing high-tech glass enamel to specialized steel at temperatures exceeding 820°C, we create a surface that is immune to the corrosive nature of agricultural waste.

Corrosion Resistance: GFS is virtually impervious to high-ammonia and sulfide environments, ensuring a service life that supports long-term farm operations.

Modular Versatility: The bolted design allows for fast on-site assembly, enabling farms to expand their treatment capacity as their livestock numbers grow.

2. Epoxy Coated Tanks: Specialized Process Support

As a critical part of our infrastructure portfolio, Center Enamel Epoxy Coated Tanks provide an excellent solution for auxiliary stages.

Advanced Coating Technology: Our epoxy tanks utilize a high-specification electrostatic powder coating process. This results in a smooth, durable finish that provides excellent resistance against organic residues and treated liquid.

Versatile Application: These tanks are ideal for equalization, storage of treated liquid effluent, or as buffer tanks for incoming sewage. They offer a cost-effective yet highly durable alternative where high corrosion resistance is essential, ensuring the entire facility maintains a consistent standard of quality.

Factory-Controlled Precision: Every tank is manufactured under strict conditions to ensure consistent coating thickness and superior bond strength, providing a reliable long-term storage solution.

3. Double Membrane Roofs: The Core of Energy Recovery and Sealing

In modern anaerobic digestion (AD) projects, the Double Membrane Roof (air-supported membrane system) is not merely a cover; it is a central component of the "waste-to-energy" system.

Efficient Storage and Pressure Regulation: The roof consists of an inner and an outer high-strength flexible membrane. The inner membrane stays in contact with the biogas and adjusts its volume based on production, while the outer membrane is pressurized by a constant-pressure blower to maintain its shape. This design buffers gas production peaks and ensures a stable supply of biogas.

Rigorous Sealing Performance: The double membrane system is connected to the top of the GFS tank via a specialized sealing structure, achieving nearly total airtightness. This prevents the leakage of methane (a potent greenhouse gas) and ensures zero odor in the surrounding environment.

All-Weather Protection: The outer membrane is treated for UV resistance, mold resistance, and flame retardancy. It can withstand high winds and heavy snow, protecting the internal anaerobic environment from external temperature fluctuations.

Resource Recovery: Turning Waste into "Green Gold"

As a forward-thinking China Pig Farm Wastewater Treatment Processes Contractor, Center Enamel focuses on turning an environmental liability into a financial asset.

1. Biogas Harvest with Double Membrane Roofs

In the anaerobic digestion stage, capturing methane is vital. Our Double Membrane Roof systems feature an inner gas-holding membrane and a pressurized outer protective membrane. This ensures zero methane leakage and allows the farm to recover biogas for use in CHP (Combined Heat and Power) units, potentially providing the electricity and heat required for the entire facility.

2. Water Reclamation and Fertilizer Production

The treated digestate is a nutrient-rich liquid. Our processes ensure this liquid is stabilized and safe for land application, closing the nutrient loop on the farm and reducing the need for synthetic fertilizers.

Global Project Excellence: Center Enamel Project Cases

Our standing as a premier China Pig Farm Wastewater Treatment Processes Contractor is validated by our extensive list of livestock-specific installations:

Muyuan Group Breeding Wastewater Projects Across various locations in Hunan, Henan, and Heilongjiang, we have deployed multiple high-capacity units (typically two units per site) for managing massive volumes of high-load animal waste. These projects demonstrate our ability to deliver integrated biological solutions that ensure asset integrity even in extreme climates.

Beijing Pig Farm Wastewater Treatment Project Center Enamel collaborated with a major breeding company to design a bespoke sewage storage and treatment solution. By leveraging site-specific data and water quality characteristics, we provided a tailored tank system that ensures the farm meets strict regulatory discharge standards while optimizing operational efficiency.

Henan Livestock Wastewater Project This significant project required the integration of eight units into a multi-stage industrial treatment facility. The high number of GFS and supporting tanks confirms our ability to deliver the highly specialized, compartmentalized containment solutions necessary for phased agricultural treatment.

Why Partner with Center Enamel?

Choosing Center Enamel as your China Pig Farm Wastewater Treatment Processes Contractor provides several strategic advantages:

International Standards: Our equipment meets globally recognized standards, including AWWA D103-09, ISO 28765, and NSF/ANSI 61.

Rapid Deployment: The modular bolted design allows for fast on-site assembly, minimizing disruption to farm operations.

Technical Acumen: With over thirty years of experience and more than 20 enamel formula patents, we offer unmatched expertise in material science and process engineering.

Global Support: With projects in over one hundred countries, we provide the logistical and technical support necessary for international agricultural success.

Engineering the Foundation of the Sustainable Farm

The successful execution of a modern livestock strategy relies on the reliability, efficiency, and modularity of the Pig Farm Wastewater Treatment Processes infrastructure used. By selecting a specialized China Pig Farm Wastewater Treatment Processes Contractor like Center Enamel, organizations secure a foundation of certified, modular, and durable infrastructure.

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are dedicated to providing the innovation and engineering excellence that make these projects a success. From our premier GFS tanks and high-performance Epoxy Coated Tanks to our specialized Aluminum Dome Roofs, we offer a total containment solution designed for the future of agricultural sustainability. Our commitment to quality ensures that every project we undertake is built to perform and engineered to last.