Continuous Stirred-Tank Reactor (CSTR) for Citrus Processing Wastewater Treatment Project

The processing of citrus fruits—for juice, essential oils, and concentrates—generates a distinct and challenging wastewater stream. Effluent from a Citrus Processing Wastewater Treatment Project is characterized by extremely high organic loads, high acidity due to citric acid, and the presence of significant amounts of suspended solids and colloidal materials like pectin and pulp fines. These factors combine to create an environment that can easily lead to acidification and system failure in conventional anaerobic reactors.

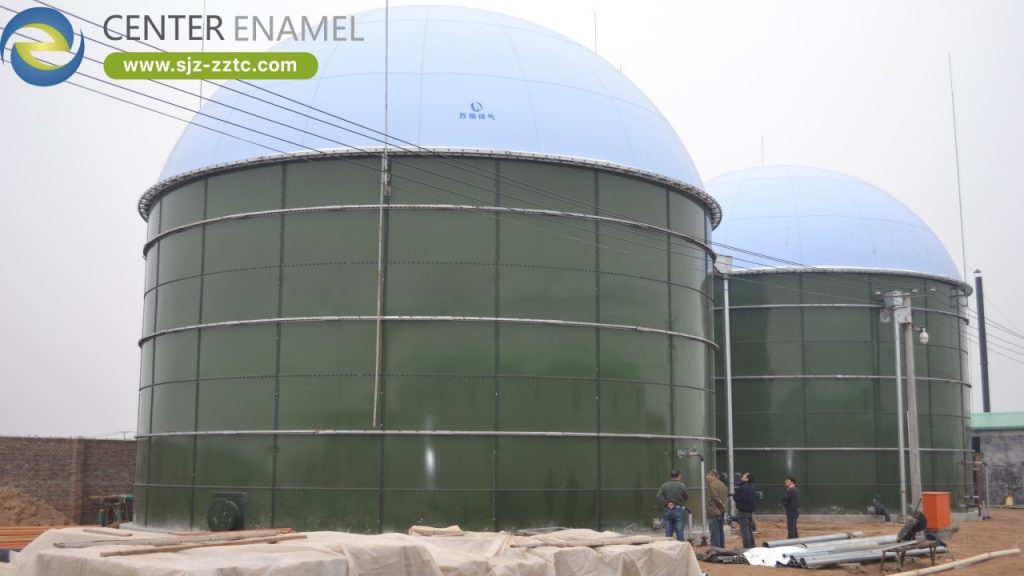

Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) advocates for the Continuous Stirred-Tank Reactor (CSTR) System as the most reliable and effective anaerobic technology for this sector. The CSTR's full mixing capability is uniquely suited to handle the high solids and acidic shocks inherent in citrus waste, ensuring rapid homogenization and stable biogas generation. Contained within our highly durable and chemically resistant Glass-Fused-to-Steel (GFS) tanks, the CSTR provides the resilient core needed for a sustainable and profitable Citrus Processing Wastewater Treatment Project.

The Dual Challenge of Citrus Processing Effluent

Successfully managing a Citrus Processing Wastewater Treatment Project hinges on mitigating the specific challenges presented by fruit chemistry and processing techniques:

High Organic Acidity and Shock: Wastewater is often highly acidic (low pH) due to residual citric acid. Furthermore, the high concentration of rapidly biodegradable sugars leads to instantaneous volatile fatty acid (VFA) generation upon entering the reactor. This combination poses a severe risk of pH crash and microbial inhibition.

Pectin and Suspended Solids: The presence of pectin (a colloidal polysaccharide) and residual pulp/peel fines significantly increases the viscosity and suspended solids (TSS). In non-mixed systems, these materials can float, cause crusting, or interfere with sludge granular integrity, leading to washout and reduced efficiency.

Batch Variability: Processing seasons and cleaning cycles result in dramatic and unpredictable fluctuations in wastewater flow, organic load, and temperature. A stable reactor must be able to buffer these shock loads immediately.

Nutrient Imbalance: Citrus waste often has a high Carbon-to-Nutrient ratio, requiring precise control and nutrient addition, which is best achieved in a fully mixed environment.

The CSTR design provides the essential hydraulic and chemical homogenization necessary to overcome these hurdles, making it the superior choice for any Citrus Processing Wastewater Treatment Project.

Technical Mastery: CSTR Stability Against Acidity and Solids

The Continuous Stirred-Tank Reactor (CSTR) System is a cornerstone of industrial anaerobic treatment because its design directly addresses the physical and chemical instability of complex organic effluents.

pH and Shock Load Buffering via Full Mixing

The primary advantage of the CSTR in citrus applications is the guaranteed uniformity provided by its continuous and robust mixing system:

Immediate pH Neutralization: Incoming acidic effluent or rapid VFA spikes are instantly diluted and neutralized by the alkalinity already present in the large volume of mixed liquor. This instantaneous buffering prevents the critical drop in pH that can inhibit or kill methanogenic bacteria.

Homogenization of Pectin and Solids: The continuous stirring keeps colloidal solids, pectin, and fine pulp particles in suspension. This prevents the formation of thick scum layers (crusting) that can block gas collectors and disrupt mass transfer, a common failure point in unmixed digesters processing citrus waste.

Optimal Mass Transfer: The intimate contact maintained between the biodegradable organic substrate and the suspended microbial sludge maximizes the rate of hydrolysis and acidogenesis. This constant interaction is essential for rapid COD conversion, leading directly to optimal biogas production.

High Biogas Conversion and Operational Flexibility

For a Citrus Processing Wastewater Treatment Project, maximizing energy recovery from the highly soluble sugar load is a key economic driver.

Maximum Methane Yield: The CSTR’s stable pH and efficient mixing guarantee the highest possible conversion of soluble organic matter into methane. This high biogas yield can be used on-site for heat or power, providing significant operational cost offsets.

Simplified Solids Handling: The fully suspended sludge simplifies the reactor's mechanical cleaning requirements and provides flexibility in handling sludge age and retention. The continuous outflow ensures that the removal of inert solids is managed efficiently without complex internal settling mechanisms.

Acclimatization and Stability: The completely mixed environment allows the microbial community to quickly adapt to the specific organic compounds present in citrus waste, ensuring long-term stable performance regardless of the fluctuating nature of the Citrus Processing Wastewater Treatment Project influent.

GFS Tanks: The Durable Vessel for Acidic and High-Load Environments

The aggressive nature of citrus effluent—with its organic acids, high temperatures, and potential for sulfide generation—requires a containment solution with guaranteed durability and chemical resistance. Center Enamel’s Glass-Fused-to-Steel (GFS) tanks provide this essential, long-term integrity.

Superior Acid and Corrosion Resistance: The GFS tank panels feature a smooth, chemically inert glass coating fused to the steel. This barrier provides unparalleled resistance to the organic acids (VFA) and low pH conditions found within the CSTR environment, far exceeding the lifespan and performance of standard epoxy or concrete.

Structural Strength for Mixing Loads: CSTR systems require heavy, specialized mixing equipment. The GFS tank, constructed from high-strength steel, is engineered to safely support the substantial mechanical loads and hydraulic stresses imposed by continuous, powerful stirring.

Guaranteed Gas-Tightness: The safe and complete capture of high-volume methane-rich biogas is non-negotiable. The precision-engineered modular design of the GFS tank ensures a gas-tight enclosure, preventing fugitive emissions and maximizing the energy resource derived from the Citrus Processing Wastewater Treatment Project.

Rapid Deployment and Low Maintenance: The modular nature of GFS tanks allows for significantly faster construction than concrete, accelerating project completion. Furthermore, the non-adherent glass surface reduces scaling and fouling, leading to lower long-term maintenance costs.

Project Cases

Center Enamel has a robust track record of providing high-capacity GFS tank containment for high-load food, beverage, and industrial streams globally, directly supporting the challenges faced by Citrus Processing Wastewater Treatment Projects and similar facilities.

Guangdong Dairy Wastewater Treatment Project: We supplied containment for a high-load, highly organic industrial application. This project involved 3 units with a total capacity of 1,032 cubic meters, showcasing our ability to support demanding food processing waste streams.

Yili Group Hebei Langfang Dairy Wastewater Treatment Project: A large-scale food and beverage application. This installation consisted of 1 unit with a total capacity of 871 cubic meters, demonstrating our specialized solutions for the high-volume dairy/beverage sector.

Mengniu Group Heilongjiang Dairy Wastewater Treatment Project: We provided anaerobic digester containment for another major dairy producer. This project involved 1 unit with a total capacity of 1,078 cubic meters, affirming the trust placed in our GFS tanks by leading food manufacturers.

Xinjiang Urumqi Food Wastewater Treatment Project: We supplied containment for a significant regional food processing facility. This installation included 1 unit with a total capacity of 1,762 cubic meters, highlighting our capability in high-load, variable organic waste treatment.

Guizhou Industrial Wastewater Treatment Project: We provided robust containment for a general industrial wastewater facility. This project involved 1 unit with a total capacity of 1,125 cubic meters, showcasing the versatility of our tanks across diverse industrial sectors.

Guizhou Tongren Food Waste Treatment Project: A highly relevant anaerobic digestion application using food waste. This project involved 2 units with a total capacity of 2,934 cubic meters, underscoring our expertise in managing high-solids, high-organic load digestion systems suitable for Citrus Processing Wastewater Treatment Project needs.

Conclusion

For sustainable operation of a Citrus Processing Wastewater Treatment Project, stability is paramount. The Continuous Stirred-Tank Reactor (CSTR) System provides the necessary resilience by instantly homogenizing pH shocks and effectively managing high solids and pectin loads. By integrating this advanced technology with the superior chemical resistance and structural integrity of Center Enamel’s GFS tanks, citrus processors gain a reliable, energy-generating platform that maximizes biogas recovery, minimizes operational complexity, and ensures long-term environmental and economic success. Partner with Center Enamel for a cutting-edge CSTR solution tailored to the unique demands of citrus waste.