Converting Swine Effluent to Power: Designing the Optimal Biogas Plant for Pig Farm Wastewater Management

The swine industry is a cornerstone of global agriculture, yet its rapid growth and intensive operations present immense challenges in waste management. Pig manure and wastewater, recognized for their high organic concentration and potent pollutant load, necessitate specialized and effective handling. Traditional methods of lagoon storage or land application are increasingly unsustainable, leading to regulatory pressures, environmental degradation, and significant odor issues.

The modern solution lies in transforming this environmental liability into a valuable energy asset. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) specializes in the design, engineering, and supply of the foundational infrastructure for high-efficiency Biogas Plant installations dedicated to Pig Farm Wastewater Management. Our technology enables large-scale swine operations to achieve a true circular economy: converting effluent into self-generated power, heat, and nutrient-rich fertilizer.

By centering these critical anaerobic systems around our proprietary Glass-Fused-to-Steel (GFS) tanks, Center Enamel ensures an exceptionally durable, gas-tight, and corrosion-resistant containment solution. This foundation is essential for maximizing biogas yield, securing long-term operational reliability, and establishing the farm as a leader in sustainable, energy-independent agriculture.

The Unique Challenges and Opportunities of Pig Farm Effluent

Pig Farm Wastewater Management presents unique hurdles that make the design of the Biogas Plant crucial for success. However, the characteristics of swine effluent also offer unparalleled opportunities for renewable energy generation.

1. The Complex Nature of Swine Waste

Pig effluent is characterized by its density and high biological activity:

Extreme Organic Load: Swine waste has one of the highest concentrations of organic matter among all agricultural effluents, resulting in an exceptionally high Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD). This high energy density makes it an optimal feedstock for anaerobic digestion, leading to a high yield of methane-rich biogas.

High Solids and Viscosity: The waste stream often contains substantial total solids and suspended solids, giving it a thick, viscous consistency. The Biogas Plant must utilize appropriate pre-treatment and specialized reactor designs capable of handling this dense input without clogging or settling.

Corrosive Elements: The anaerobic decomposition of high-protein swine waste generates significant amounts of hydrogen sulfide gas. This gas, when dissolved, is highly corrosive to standard steel and concrete. The reactor containment must be specifically engineered to resist this aggressive environment over decades.

Pathogen and Nutrient Concerns: Raw effluent is a source of pathogens and concentrated nutrients, including nitrogen and phosphorus. Effective Pig Farm Wastewater Management must include measures to destroy pathogens and stabilize nutrients, making the final byproducts safe for reuse.

2. The Economic Case for Biogas Energy

For large-scale swine operations, installing a Biogas Plant shifts the economic equation from a waste disposal cost center to a critical revenue generator:

Energy Self-Sufficiency: Swine facilities require constant ventilation, heating (especially for farrowing houses), and electricity for feed systems and processing. Biogas captured from the effluent can power a Combined Heat and Power (CHP) unit, satisfying a substantial portion of the farm's total energy demand and providing insulation from rising utility costs.

Value-Added Byproducts: The final product, digestate, is a stable, de-odorized, and highly effective fertilizer. Selling or utilizing this digestate reduces the need for costly chemical fertilizers while simultaneously eliminating landfill or disposal fees for raw sludge.

Carbon Credit and Regulatory Incentives: By capturing methane, a potent greenhouse gas, and utilizing it as fuel, farms significantly reduce their carbon footprint, potentially qualifying for carbon credits and meeting increasingly stringent environmental regulations for Pig Farm Wastewater Management.

Designing the Optimal Biogas Plant: Reactor and Process

A successful Biogas Plant for swine effluent relies on a robust reactor and a well-integrated system design optimized for high-solids, high-COD input.

1. Reactor Technology Selection

The choice of reactor is dictated by the density and consistency of the manure slurry:

Continuous Stirred Tank Reactors (CSTR): For manure mixed with dilution water (slurry), CSTRs are often preferred. They ensure continuous and complete mixing, allowing fresh feedstock to mix uniformly with the active microbial biomass. The robust mixing mechanism within the GFS tank must be powerful enough to prevent heavy solids from settling at the bottom.

Pre-Treatment Systems: Screening and solid-liquid separation equipment are often deployed before the reactor to manage excessive solids, grit, and foreign objects, preventing damage to downstream pumps and optimizing the feedstock consistency for maximal biogas yield.

2. Center Enamel’s Role in Containment Integrity

The GFS tank serves as the immune system of the Biogas Plant, ensuring operational continuity despite the corrosive internal environment.

Hydrogen Sulfide Resistance: The high concentration of hydrogen sulfide in swine biogas is corrosive. GFS tanks, with a chemically inert glass layer molecularly fused to the steel, provide a long-term, impermeable barrier against this corrosion, drastically outlasting epoxy, paint, or standard concrete linings.

Structural Resilience for Mixing: The powerful agitators required to mix dense swine slurry exert immense force on the tank walls. Our high-strength GFS panels are engineered to bear these mechanical stresses, guaranteeing structural stability and the long-term integrity of the Biogas Plant.

Guaranteed Gas-Tightness: The primary purpose of the Biogas Plant is energy capture. The precision engineering of our bolted GFS panels, combined with specialized industrial sealants, ensures a superior, permanent gas-tight seal at all panel joints, maximizing methane recovery and maintaining safety standards.

The GFS Advantage in Pig Farm Wastewater Management

Center Enamel’s Glass-Fused-to-Steel (GFS) technology offers pig farm operators clear economic and operational superiority over conventional containment methods like poured concrete or stainless steel.

1. Cost-Effectiveness and Lifespan

The long-term value of GFS drastically outweighs its initial cost:

Decades of Service Life: Unlike epoxy or coated steel, which degrade over time and require re-coating, the inorganic glass fusion provides a life cycle extending well beyond typical concrete or steel options, virtually eliminating internal maintenance costs.

Rapid, Consistent Construction: The modular, bolt-together nature of GFS tanks allows for incredibly fast installation, regardless of local weather conditions. This reduced construction time minimizes disruptions to Pig Farm Wastewater Management operations and allows the Biogas Plant to begin generating energy and revenue sooner.

Low Maintenance Requirements: The smooth, inert glass surface of the tank interior resists the buildup of sludge, scale, and biofilm. This self-cleaning property minimizes manual cleaning and maintenance downtime, maximizing the reactor’s operational uptime.

2. Scalability and Quality Assurance

GFS technology is built for the rapid expansion and rigorous quality demands of modern swine farming:

Modular Scalability: Should the farm expand its swine population, the GFS Biogas Plant can be easily enlarged by adding new rings of panels to increase height or by adding adjacent tanks, providing built-in flexibility for future growth.

Factory-Controlled Quality: Every component of the GFS tank is manufactured under stringent quality controls in our factory, ensuring the uniformity of the glass coating and the precision of the panel dimensions, eliminating the variability and potential flaws inherent in on-site construction methods like concrete pouring.

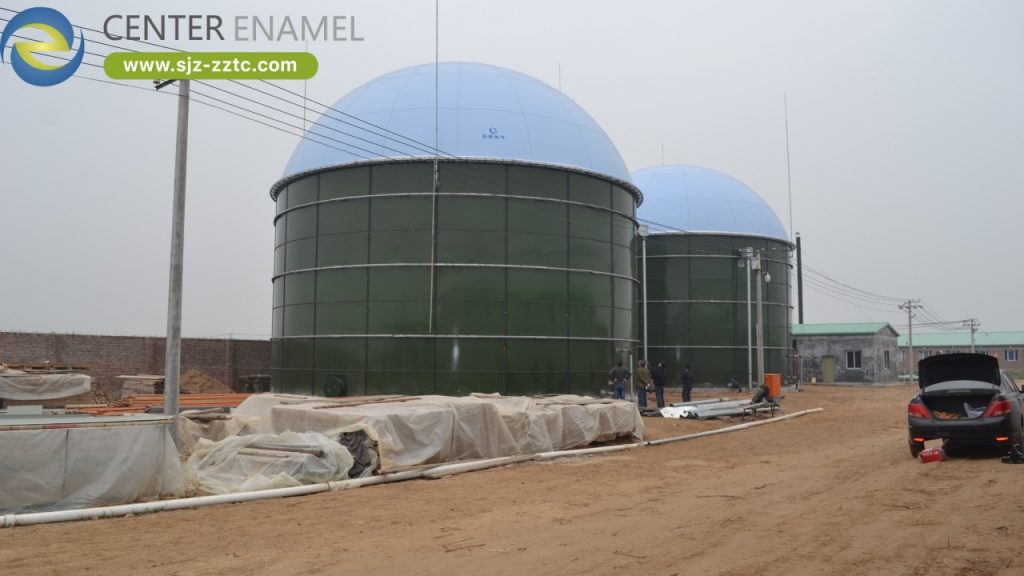

Compatibility with Covers: GFS tanks are perfectly suited to accommodate gas-tight aluminum dome roofs or double membrane gas holders, which are essential for storing and managing the biogas generated by the Biogas Plant.

Project Cases

Center Enamel is a trusted partner for major agricultural corporations, providing the robust GFS containment necessary to ensure the efficiency and longevity of Biogas Plant installations dedicated to Pig Farm Wastewater Management.

The following projects showcase our core competency in delivering precise, high-volume containment solutions for high-load organic effluent:

Shanghai Songlin Pig Farm Wastewater Project: This project involved providing GFS containment for a large-scale pig farm, demonstrating our capacity to manage high-volume, high-load organic effluent directly from swine operations. The installation consisted of 2 units with a total capacity of 6,205 cubic meters, showcasing our ability to deliver substantial high-capacity solutions tailored for Pig Farm Wastewater Management.

Muyuan Group Henan Livestock Wastewater Treatment Project: We supplied GFS containment for a major livestock project, requiring resilient infrastructure to manage aggressive organic decomposition and continuous biogas recovery. This installation involved 2 units with a total capacity of 5,954 cubic meters, affirming our expertise in executing high-capacity Biogas Plant projects where containment integrity for concentrated swine waste is essential.

Guangdong Shaoguan Livestock Wastewater Project: We provided robust containment for a multi-unit organic waste stream facility. This project consisted of 8 units with a total capacity of 5,368 cubic meters, further cementing our proven track record in supplying foundational infrastructure for diverse, multi-tank applications demanding consistent power recovery from Livestock Wastewater Treatment.

Conclusion: Securing the Future of Swine Farming

The integration of a high-efficiency Biogas Plant is no longer optional but essential for modern Pig Farm Wastewater Management. It is the most effective way to eliminate environmental risks, reduce dependency on external energy sources, and create a sustainable, profitable circular economy for the agricultural sector.

Center Enamel's Glass-Fused-to-Steel (GFS) tanks provide the necessary foundation for this transformation. Our technology guarantees the structural integrity, corrosion resistance, and gas-tight sealing required to maximize the conversion of challenging swine effluent into clean, valuable power, ensuring the long-term success and environmental leadership of our clients in the global swine industry.