Dairy Farm Wastewater Treatment Project: Generating Renewable Energy with a Dedicated Biogas Plant

The dairy industry is a pillar of global food production, but its operations generate high volumes of wastewater—a complex mix of manure, wash-down water, residual milk, and cleaning agents. This effluent presents an intensive environmental management challenge, marked by high organic load and elevated nutrient concentrations that pose risks to local water bodies and air quality.

However, modern engineering recognizes this high organic concentration as a strategic energy opportunity. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) specializes in providing the essential infrastructure for successful Dairy Farm Wastewater Treatment Project implementation. Our solutions focus on integrating high-efficiency anaerobic digestion into a robust Biogas Plant, thereby transforming manure and parlor wash-down into a sustainable source of power and heat.

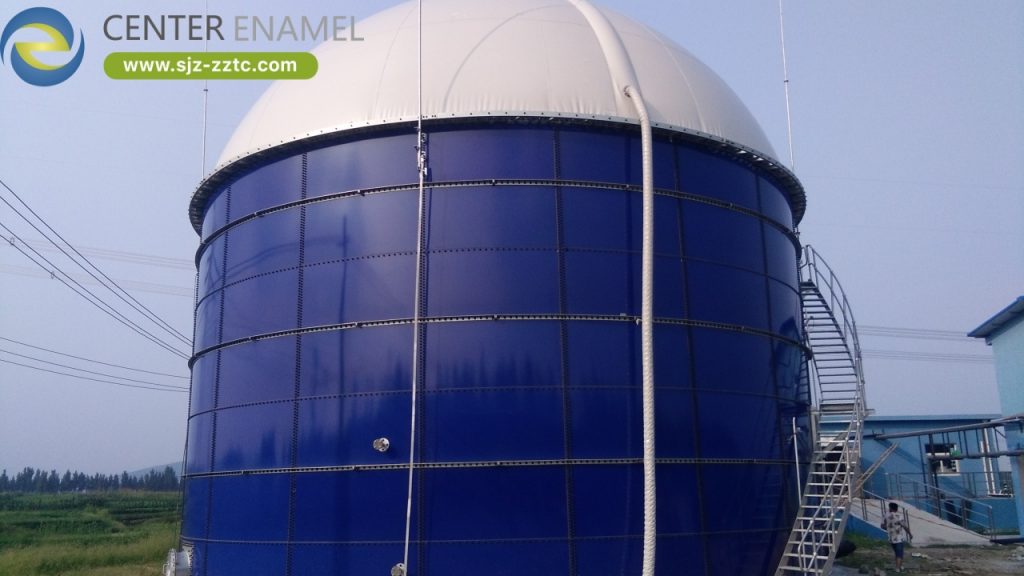

By supplying our globally renowned Glass-Fused-to-Steel (GFS) tanks as the core reactor vessels, Center Enamel ensures that every Biogas Plant operates with maximum efficiency, unparalleled durability, and long-term cost-effectiveness. This strategy allows dairy farms to move beyond simple waste disposal, achieving stringent environmental compliance while securing reliable, on-site renewable energy.

The Environmental and Economic Necessity of Dairy Wastewater Treatment

Effective Dairy Farm Wastewater Treatment Project implementation is no longer optional; it is a critical component of sustainable agriculture, driven by both regulatory pressure and economic opportunity.

1. The Challenge of Dairy Effluent

Dairy wastewater, particularly the manure slurry, is a potent feedstock with unique challenges:

High Organic Concentration: The mixture of residual milk solids and manure provides a rich source of carbon, resulting in a high Chemical Oxygen Demand (COD). This density, while challenging for simple disposal, makes it highly suitable for energy recovery.

Nutrient Overload: Effluent contains significant concentrations of nitrogen and phosphorus. Without controlled treatment, these nutrients can lead to the eutrophication of local rivers and lakes.

Odor and Emissions: Uncontrolled decomposition of manure releases strong odors and large volumes of methane, a powerful greenhouse gas. Encapsulating this process within a gas-tight Biogas Plant is the only way to effectively capture and neutralize these emissions.

2. The Biogas Plant as an Economic Solution

Integrating a Biogas Plant fundamentally alters the economics of a dairy farm:

Energy Security and Cost Savings: Dairy farms are continuous, high-energy consumers, requiring constant power for milking, refrigeration, and ventilation. By using the captured biogas to fuel a Combined Heat and Power (CHP) unit, farms can generate their own electricity and thermal heat, achieving energy independence and stability against fluctuating energy costs.

Value-Added Byproducts: The anaerobic digestion process stabilizes the nutrients, transforming the raw, odorous waste into a pathogen-reduced, liquid and solid digestate that serves as a premium, ready-to-use organic fertilizer, creating a new revenue stream and reducing reliance on purchased chemicals.

Regulatory Compliance: A successful Biogas Plant dramatically reduces the pollutant load on discharge, simplifying and securing compliance with increasingly strict environmental regulations governing a Dairy Farm Wastewater Treatment Project.

Designing the High-Efficiency Dairy Biogas Plant

The optimal Biogas Plant for dairy operations is designed to handle the liquid, slurry nature of the waste while maximizing methane production.

1. Choosing the Right Reactor Technology

Dairy manure, often collected with significant wash water, is typically treated as a slurry, favoring reactor types that handle high flow and continuous input:

Continuous Stirred Tank Reactors (CSTR): CSTRs are widely adopted for dairy slurry due to their robust design and ability to handle continuous feeding. The reactor design must incorporate powerful mixing to prevent settling of residual solids and ensure maximum contact between the feedstock and the microbial community.

Thermal Pre-treatment: In some advanced Dairy Farm Wastewater Treatment Project designs, thermal processes may be used to enhance the biodegradability of the feedstock, further boosting the potential biogas yield before it enters the digester.

2. Center Enamel’s Role in Infrastructure Integrity

The digester vessel is the most critical asset in the Biogas Plant. Center Enamel’s GFS tanks ensure this asset is built for extreme durability and efficiency.

Extreme Corrosion Resistance: The interior environment of a dairy manure digester is highly aggressive due to organic acids and the high concentration of hydrogen sulfide in the biogas. The GFS tank, with its molecularly fused glass layer, provides a permanent, inert barrier that resists these corrosive agents, guaranteeing a lifespan of many decades.

Guaranteed Gas-Tight Seal: Capturing every cubic meter of methane is essential for the financial success of the Biogas Plant. Our precision-engineered GFS panels and specialized sealants provide a superior, permanent gas-tight seal, ensuring safe operation and maximum biogas recovery.

Structural Strength for Slurry: Dairy slurry is dense and exerts significant hydrostatic pressure. GFS tanks are engineered with high-strength steel and robust structural support to safely contain these large volumes, as well as the mechanical stresses imposed by powerful internal mixing systems.

The GFS Tank Advantage in Dairy Farm Wastewater Treatment

Center Enamel’s Glass-Fused-to-Steel (GFS) technology provides strategic, long-term operational benefits that secure the success of every Dairy Farm Wastewater Treatment Project.

1. Efficiency and Cost Reduction

Choosing GFS optimizes both construction and operational phases:

Speed of Installation: GFS tanks are manufactured off-site and rapidly bolted together on the dairy farm. This speed of construction minimizes downtime, accelerates project completion, and allows the Biogas Plant to start generating revenue and energy much faster than traditional construction methods.

Low Maintenance Cost: The smooth, inert glass surface of the tank interior resists the adhesion of biological film and scale buildup. This dramatically reduces the need for manual cleaning and costly periodic maintenance, increasing the operational uptime of the entire system.

Adaptability and Scalability: As dairy herd sizes fluctuate or grow, GFS tanks can be easily expanded in capacity by adding ring sections. Their modular nature also allows for simplified relocation or repurposing, providing flexibility that concrete structures cannot match.

2. Commitment to Quality and Safety

Center Enamel ensures that the containment system meets the highest international standards for biogas applications:

Manufacturing Precision: All GFS panels undergo strict quality control testing in our state-of-the-art facility, ensuring the consistency of the glass coating and the dimensional accuracy required for a perfect, gas-tight fit on-site.

Compatibility with Gas Holders: Our tanks are specifically designed to integrate seamlessly with various biogas storage solutions, including double membrane gas holders or specialized fixed roofs, which are critical components of a modern Biogas Plant for managing the generated gas.

Reliability in Remote Locations: GFS components are easy to ship and assemble anywhere in the world, making them the preferred choice for large-scale, often remote Dairy Farm Wastewater Treatment Project locations where skilled concrete labor or harsh weather conditions can compromise traditional construction.

Project Cases

Center Enamel is a trusted infrastructure supplier to global dairy and food processing leaders, providing the robust GFS containment necessary for efficient Biogas Plant installation and the long-term success of every Dairy Farm Wastewater Treatment Project.

The following projects showcase our core competency in delivering precise, high-volume containment solutions for dairy and related organic effluent:

Mengniu Group Heilongjiang Dairy Wastewater Treatment Project: This project demonstrates our capacity to handle organic effluent from major dairy producers, which requires durable, gas-tight containment for efficient biogas recovery. The installation consisted of 1 unit with a total capacity of 1,078 cubic meters, showcasing our ability to deliver substantial high-capacity solutions tailored for a Dairy Farm Wastewater Treatment Project.

Yili Group Hebei Langfang Dairy Wastewater Treatment Project: We supplied GFS containment for another significant dairy operation, requiring resilient infrastructure to manage high-volume wash-down and decomposition processes. This installation involved 1 unit with a total capacity of 871 cubic meters, affirming our expertise in executing single-unit Biogas Plant projects where containment integrity for food industry wastewater is essential.

Anhui Huainan Dairy Wastewater Treatment Project: We provided robust containment for a multi-unit dairy wastewater facility. This project consisted of 2 units with a total capacity of 664 cubic meters, further cementing our proven track record in supplying foundational infrastructure for diverse, high-strength industrial applications demanding consistent energy recovery from dairy waste.

Conclusion: Securing Sustainability and Profitability

The modern Dairy Farm Wastewater Treatment Project is fundamentally changing its focus—from disposal to resource recovery. The installation of a high-efficiency Biogas Plant represents the most effective strategy for managing dairy effluent, transforming manure slurry into valuable, self-generated power and high-quality fertilizer.

By partnering with Center Enamel and deploying our industry-leading Glass-Fused-to-Steel (GFS) tanks, dairy operators secure a foundation of unmatched durability, chemical resilience, and guaranteed gas-tight integrity. This robust containment is crucial for maximizing biogas yield, achieving long-term energy independence, and establishing the dairy farm as a leader in sustainable, financially sound agricultural practice.