Dairy Wastewater Treatment Project: Powering the Farm with an Integrated Biogas Power Plant

The modern dairy industry, a critical global food producer, generates a consistent and substantial stream of wastewater—a complex effluent containing manure, wash-down water, residual milk solids, and cleaning agents. While essential for hygiene, this high-volume waste presents significant challenges, particularly its high organic load and concentrated nutrients, which demand intensive environmental management. Ignoring these challenges leads to regulatory fines, rising disposal costs, and environmental degradation.

The most viable and forward-thinking solution is to reclassify this waste from a liability to a resource. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) specializes in providing the essential infrastructure to transform any Dairy Wastewater Treatment Project into a self-sustaining energy center. We accomplish this by integrating high-efficiency anaerobic digestion into a dedicated Biogas Power Plant.

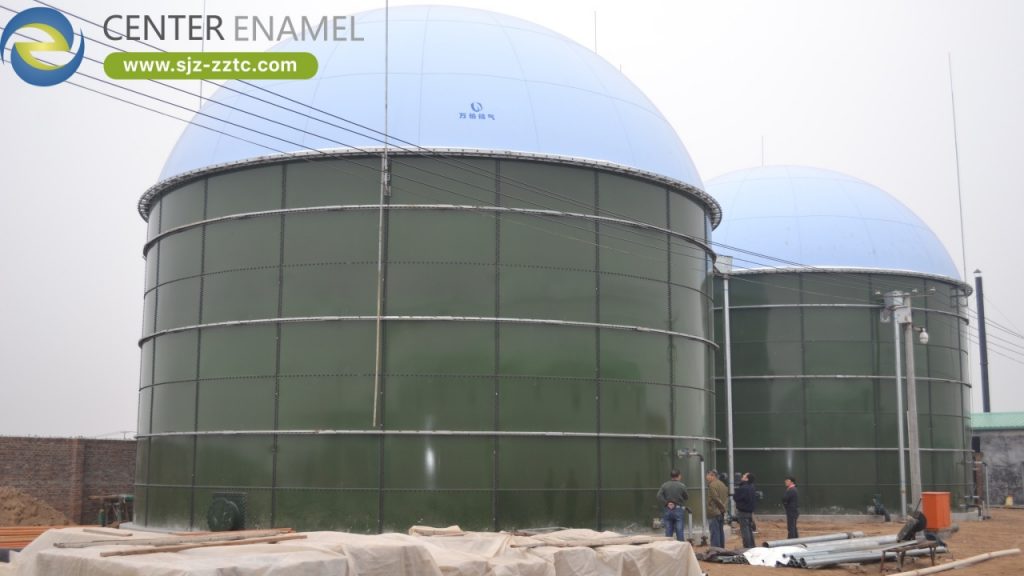

By supplying our globally utilized Glass-Fused-to-Steel (GFS) tanks as the core containment vessels, Center Enamel ensures that every Biogas Power Plant is built on a foundation of chemical resilience, structural integrity, and guaranteed gas-tightness. This strategy enables dairy farms to secure stringent environmental compliance while achieving robust energy independence through on-site power and heat generation, driving a truly profitable and circular agricultural economy.

The Strategic Case for Biogas in Dairy Farming

The push for integrating a Biogas Power Plant into a Dairy Wastewater Treatment Project is fueled equally by strict environmental mandates and powerful economic incentives.

1. Addressing the Environmental Load

Dairy effluent requires specialized treatment due to its unique composition:

High Organic Concentration (COD/BOD): The combination of manure and residual milk solids results in an exceptionally rich organic load. This concentration, while a pollution risk, translates directly into high potential for methane generation, the fuel for the Biogas Power Plant.

Nutrient Management: Wastewater is laden with nitrogen and phosphorus. Controlled anaerobic digestion, followed by proper post-treatment, is essential to stabilize these nutrients and prevent runoff that causes water body pollution.

Methane and Odor Control: Allowing dairy waste to decompose naturally in open lagoons releases methane, a potent atmospheric gas, and generates pervasive odors. Enclosing the digestion process in a sealed GFS tank and utilizing the resulting gas effectively eliminates both the odor nuisance and the environmental impact of uncontrolled emissions.

2. The Economic Payoff of Powering the Farm

The financial returns of operating an integrated Biogas Power Plant are substantial for large-scale dairy farms:

Energy Cost Elimination: Dairy farms require massive, continuous electricity for milking parlors, refrigeration, lighting, and ventilation, along with thermal energy for cleaning and maintaining digester temperature. Generating power and heat directly from the farm’s own waste eliminates dependency on the commercial grid and locks in stable, low energy costs.

Fertilizer Value: The anaerobic process converts raw, odorous manure into stabilized, pathogen-reduced digestate. This product is a superior organic fertilizer that can be reused on fields, reducing or eliminating the farm's need to purchase costly synthetic chemical fertilizers.

Long-Term Resilience: Investing in a Biogas Power Plant provides the farm with operational resilience, insulating it against rising disposal fees, volatile utility prices, and future changes in environmental regulation, ensuring the long-term viability of the Dairy Wastewater Treatment Project.

Designing the Integrated Biogas Power Plant

The ideal Biogas Power Plant for a Dairy Wastewater Treatment Project must be engineered to efficiently handle large volumes of high-solids, liquid slurry while maintaining stable operating conditions for continuous energy output.

1. Core Reactor Technology

Dairy manure, often collected with significant wash water, is treated as a slurry, favoring reactor systems designed for high flow and continuous feeding:

Continuous Stirred Tank Reactors (CSTR): CSTRs are the preferred technology, ensuring that fresh slurry mixes completely with active biomass, maximizing reaction kinetics and biogas yield. The design of the containment must accommodate the installation of powerful, reliable internal mixing equipment to prevent solid settling.

Feedstock Blending: The system must be capable of handling various dairy inputs, including liquid manure, parlor wash-down, and potentially expired milk or food processing waste. Pre-treatment and blending tanks, also contained in robust GFS vessels, ensure the feedstock is uniform and optimized for the digester.

The Power Generation Cycle: The captured biogas is channeled to a Combined Heat and Power (CHP) unit. This unit serves the farm's energy needs by generating electricity, and crucially, capturing waste heat. This thermal energy is then recycled to heat the digester or nearby buildings, achieving exceptional overall system efficiency.

2. Center Enamel’s Containment Role: GFS as the Foundation

The containment vessel for the digester is the single most critical asset, and Center Enamel’s GFS tanks provide the necessary guarantees of performance and longevity.

Unmatched Corrosion Protection: The presence of sulfides and organic acids in the dairy digestate creates a fiercely corrosive environment. The GFS tank’s molecularly fused, inert glass layer acts as an impermeable barrier, completely resisting this chemical attack for decades. This eliminates the need for costly maintenance or replacement associated with standard steel or concrete.

Structural Integrity for Slurry: Dairy slurry is heavy and dense. GFS tanks are engineered using high-strength steel panels to withstand the immense hydrostatic loads, the pressure from internal mixing systems, and the dynamic stresses inherent in a large-scale Biogas Power Plant operation.

Guaranteed Gas Management: The GFS system utilizes precision-fit, bolted panels and specialized sealants to create a superior, permanent gas-tight seal at all joints. This is essential for preventing dangerous leaks, complying with regulations, and maximizing the quantity of methane captured for the Biogas Power Plant.

The GFS Advantage in Dairy Wastewater Treatment

Center Enamel’s Glass-Fused-to-Steel (GFS) technology offers dairy operators profound strategic and economic advantages over traditional containment solutions.

1. Long-Term Value and Maintenance

GFS tanks are an investment in the long-term operational success of the Dairy Wastewater Treatment Project:

Minimal Maintenance: The smooth glass surface is anti-adherent, resisting the buildup of biological film and scale common with manure. This self-cleaning characteristic drastically reduces the need for manual cleaning and extends the operational life of the reactor without intervention.

Rapid Installation, Lower Risk: GFS components are prefabricated and assembled quickly on-site, minimizing the project construction timeline and reducing labor costs. This accelerated process allows the Biogas Power Plant to become operational faster, speeding up the return on investment.

Flexibility and Expansion: The modular GFS design allows for simplified capacity increases, either by adding more tanks or expanding existing tanks in height. This unique flexibility is critical for farms planning for future herd growth.

2. Quality, Safety, and Global Reliability

Center Enamel ensures that its infrastructure supports the highest standards of safety and reliability:

Factory-Controlled Quality: Every panel is manufactured and tested in our controlled facility, guaranteeing the consistency of the glass fusion and panel precision. This eliminates the structural and coating quality risks associated with conventional on-site construction.

Seamless Integration: GFS tanks are designed to integrate perfectly with various necessary components of a modern Biogas Power Plant, including heating coils, external pumping systems, and specialized gas holding covers, ensuring the overall system functions as a highly efficient unit.

Proven Global Track Record: GFS technology has been successfully deployed across the globe in the most aggressive industrial and agricultural environments, proving its status as the most reliable containment choice for a long-term Dairy Wastewater Treatment Project.

Project Cases

Center Enamel is a trusted infrastructure supplier to global dairy and food processing leaders, providing the robust GFS containment necessary for efficient Biogas Power Plant installation and the long-term success of every Dairy Wastewater Treatment Project.

The following projects showcase our core competency in delivering precise, high-volume containment solutions for high-load dairy, livestock, and industrial organic effluent:

Henan Mengniu Dairy Industrial Wastewater Project: This project demonstrates our capacity to handle organic effluent from a major dairy producer, requiring durable, gas-tight containment for efficient biogas recovery. The installation consisted of 1 unit with a total capacity of 2,900 cubic meters, showcasing our ability to deliver substantial high-capacity solutions tailored for a Dairy Wastewater Treatment Project and food processing operations.

Muyuan Group Henan Livestock Wastewater Treatment Project: We supplied GFS containment for a major livestock project, requiring resilient infrastructure to manage aggressive organic decomposition and continuous biogas recovery. This installation involved 1 unit with a total capacity of 3,010 cubic meters, affirming our expertise in executing high-capacity single-unit Biogas Power Plant projects where containment integrity for concentrated manure waste is essential.

Hebei Handan Industrial Wastewater Project: We provided robust containment for a large-scale industrial facility, highlighting our capability in general high-load wastewater management, which shares similar demands with dairy effluent. This project consisted of 1 unit with a total capacity of 2,698 cubic meters, further cementing our proven track record in supplying foundational infrastructure for high-strength industrial applications demanding consistent energy recovery.

Conclusion: Securing Sustainability and Profitability

The modern Dairy Wastewater Treatment Project is fundamentally changing its focus—from disposal to resource recovery. The installation of a high-efficiency Biogas Power Plant represents the most effective strategy for managing dairy effluent, transforming manure slurry into valuable, self-generated power and high-quality fertilizer.

By partnering with Center Enamel and deploying our industry-leading Glass-Fused-to-Steel (GFS) tanks, dairy operators secure a foundation of unmatched durability, chemical resilience, and guaranteed gas-tight integrity. This robust containment is crucial for maximizing methane recovery, achieving long-term energy independence, and establishing the dairy farm as a leader in sustainable, financially sound agricultural practice.