Enhancing Methane Recovery through Anaerobic Digestion of Palm Oil Mill Effluent

The global palm oil industry is currently undergoing a profound transformation. As a primary driver of economic growth in Southeast Asia and beyond, the industry is increasingly focused on reconciling its massive production scale with stringent environmental sustainability targets. One of the most significant challenges in this sector is the management of Palm Oil Mill Effluent (POME). Historically treated in open anaerobic lagoons, POME is a highly concentrated organic wastewater that represents both a significant environmental liability and a vast, untapped energy resource. Today, through the advanced Anaerobic Digestion of Palm Oil Mill Effluent, this industrial byproduct is being utilized to achieve peak Methane Recovery, turning an environmental challenge into a sustainable power source.

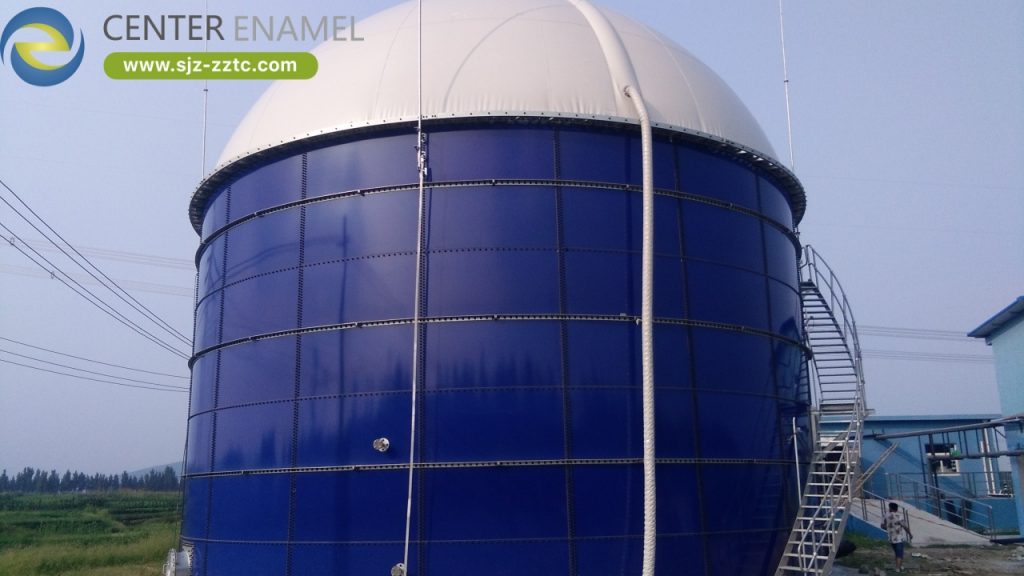

Shijiazhuang Zhengzhong Technology Co., Ltd, operating under the world-renowned brand Center Enamel, stands as a global pioneer in providing the engineering infrastructure necessary for this transition. With over thirty years of innovation and projects across more than one hundred countries, we provide the turnkey containment and processing solutions that make high-efficiency Methane Recovery a reality. Our Glass-Fused-to-Steel (GFS) technology and integrated roofing systems are specifically engineered to handle the aggressive nature of POME, ensuring long-term operational success for global palm oil producers.

The Biological and Environmental Profile of POME

To optimize Methane Recovery, one must first understand the unique and complex nature of the feedstock. Palm Oil Mill Effluent is a thick, brownish liquid characterized by a high organic load, high temperature , and an acidic pH.

1. Environmental Impact of Conventional Treatment

Traditional open lagoons allow the methane produced during natural degradation to escape into the atmosphere. Methane is a greenhouse gas with a warming potential significantly higher than carbon dioxide. Furthermore, the high organic content of POME can lead to severe water pollution if not managed within a closed, engineered system.

2. The Potential for Energy Valorization

The high concentration of oils, fats, and organic matter in POME makes it an exceptional candidate for Anaerobic Digestion. By moving treatment from open lagoons to enclosed, high-efficiency reactors, mills can capture the biogas that would otherwise be lost, utilizing it for steam generation or electricity production to power mill operations.

Technical Pathways for Optimized Methane Recovery

Achieving high-efficiency Anaerobic Digestion of Palm Oil Mill Effluent requires precise control over the biological environment to prevent process inhibition.

1. High-Rate Anaerobic Reactors

Because POME has a high Chemical Oxygen Demand, traditional treatment is slow. Center Enamel provides advanced reactor configurations, such as the Continuous Stirred-Tank Reactor (CSTR) and Anaerobic Internal Circulation (IC) systems, which are designed to handle high organic loading rates. These systems utilize mechanical mixing to ensure that the microbial consortia remain in constant contact with the organic matter, significantly accelerating the rate of Methane Recovery.

2. Temperature and pH Management

The anaerobic microorganisms responsible for producing methane are sensitive to environmental fluctuations. Since POME is discharged at high temperatures, Center Enamel’s engineering solutions include specialized cooling and heat exchange systems to bring the effluent to the mesophilic or thermophilic range, where microbial activity is most efficient. Our tanks are also engineered to withstand the acidic nature of raw POME, providing a stable environment for the pH to normalize as the digestion process proceeds.

Center Enamel’s Engineered Containment Solutions

The success of a Methane Recovery project is fundamentally dependent on the integrity of the containment vessel. POME is notoriously aggressive, and the biogas produced contains hydrogen sulfide, which can be highly corrosive to standard construction materials.

1. Glass-Fused-to-Steel (GFS) Technology: The Industrial Standard

Our flagship GFS tanks are the premier choice for the Anaerobic Digestion of Palm Oil Mill Effluent. By fusing a high-tech glass enamel coating to a specialized steel substrate at temperatures exceeding 800 degrees, we create a material that combines the structural resilience of steel with the chemical inertness of glass.

Superior Corrosion Resistance: The glass surface is impervious to the organic acids and hydrogen sulfide produced during digestion. Unlike concrete, which is porous and susceptible to acid attack, GFS provides a permanent, non-corrosive barrier.

Low Maintenance and High Durability: The hard, glossy interior of a GFS tank prevents the accumulation of residues and "scum" layers, which are common in POME treatment. This ensures that the reactor maintains its full working volume over a service life of several decades.

Modular Assembly: Our bolted design allows for rapid installation in remote plantation locations, reducing on-site construction time and labor costs.

2. Advanced Roofing for Gas Capture

To ensure Methane Recovery, the reactor must be perfectly sealed.

Double Membrane Roofs: These roofs function as an integrated gas holder. The flexible inner membrane expands to store the captured biogas, while the outer membrane provides structural protection against the tropical elements, including heavy rain and high ultraviolet radiation.

Aluminum Dome Roofs: For the storage of treated effluent or process water, our Aluminum Dome Roofs offer an unparalleled, maintenance-free solution. These geodesic domes are naturally resistant to the humid and corrosive atmosphere of a palm oil mill and require no painting or structural upkeep over their lifespan.

Sustainability and Economic Returns

Implementing advanced Anaerobic Digestion of Palm Oil Mill Effluent is a strategic investment that delivers a multi-faceted Return on Investment (ROI).

Energy Self-Sufficiency: The recovered methane can be used to generate electricity, reducing the mill’s reliance on diesel generators and fossil fuels.

Carbon Credits: By capturing methane and preventing its release into the atmosphere, palm oil mills can qualify for carbon credits under various international sustainability frameworks.

Nutrient-Rich Fertilizer: The digestate remaining after the digestion process is a stabilized, nutrient-rich organic fertilizer that can be returned to the plantation, reducing the need for expensive chemical fertilizers and completing the circular nutrient loop.

Global Project Excellence: Methane Recovery in Action

Center Enamel’s reputation as a world leader is built on a foundation of successful projects in over one hundred countries. Our containment solutions are engineered to meet the most rigorous international standards, ensuring reliability in the most challenging industrial environments.

Shandong Heze Biogas Project This significant regional energy recovery initiative utilized 3 units of our high-performance GFS tanks. The project successfully transforms concentrated organic residues into a stable energy stream, demonstrating the reliability of our tanks in high-load Methane Recovery operations.

Inner Mongolia Hinggan League Bio-Natural Gas Project A landmark project in a challenging climate, this installation successfully integrated 4 units of our bolted steel tanks. These vessels provide the stable environment necessary for the high-efficiency production of bio-natural gas from organic waste, proving the resilience of our engineering against extreme temperature fluctuations.

Jiangsu Xuzhou Biogas Project This major industrial energy project involved the deployment of 4 units of our advanced GFS containment technology. The project serves as a prime example of how modular construction can be utilized to rapidly build the essential infrastructure for modern, large-scale Anaerobic Digestion facilities.

A Greener Future for the Palm Oil Industry

The enhancement of Methane Recovery through the Anaerobic Digestion of Palm Oil Mill Effluent is a critical step toward a sustainable and profitable future for global palm oil production. By transforming a waste liability into a renewable energy asset, producers can meet their environmental obligations while improving their bottom line.

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are dedicated to providing the innovation and engineering excellence that make these projects a success. From our premier GFS tanks to our specialized Double Membrane Roofs and Aluminum Dome Roofs, we offer a total containment solution designed for the future of renewable energy and industrial sustainability.