From Effluent to Energy: Implementing Biomass Electricity Generation in Food Processing Wastewater Projects

The global food and beverage industry operates under immense pressure to increase production while simultaneously minimizing its environmental footprint. A primary challenge lies in managing the high volumes of nutrient-rich wastewater generated across various sectors, from dairies and breweries to meat and sugar processing plants. This wastewater is characterized by high concentrations of organic matter, measured as Chemical Oxygen Demand (COD), which historically presented a costly disposal problem.

Today, this paradigm has shifted. Leading companies view this organic load not as waste, but as a fuel source. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) specializes in providing the core infrastructure for Food Processing Wastewater Projects that strategically integrate Biomass Electricity Generation. Our advanced solutions harness high-efficiency anaerobic digestion to convert the wastewater's high COD directly into methane-rich biogas, which is then used to power on-site electricity generators.

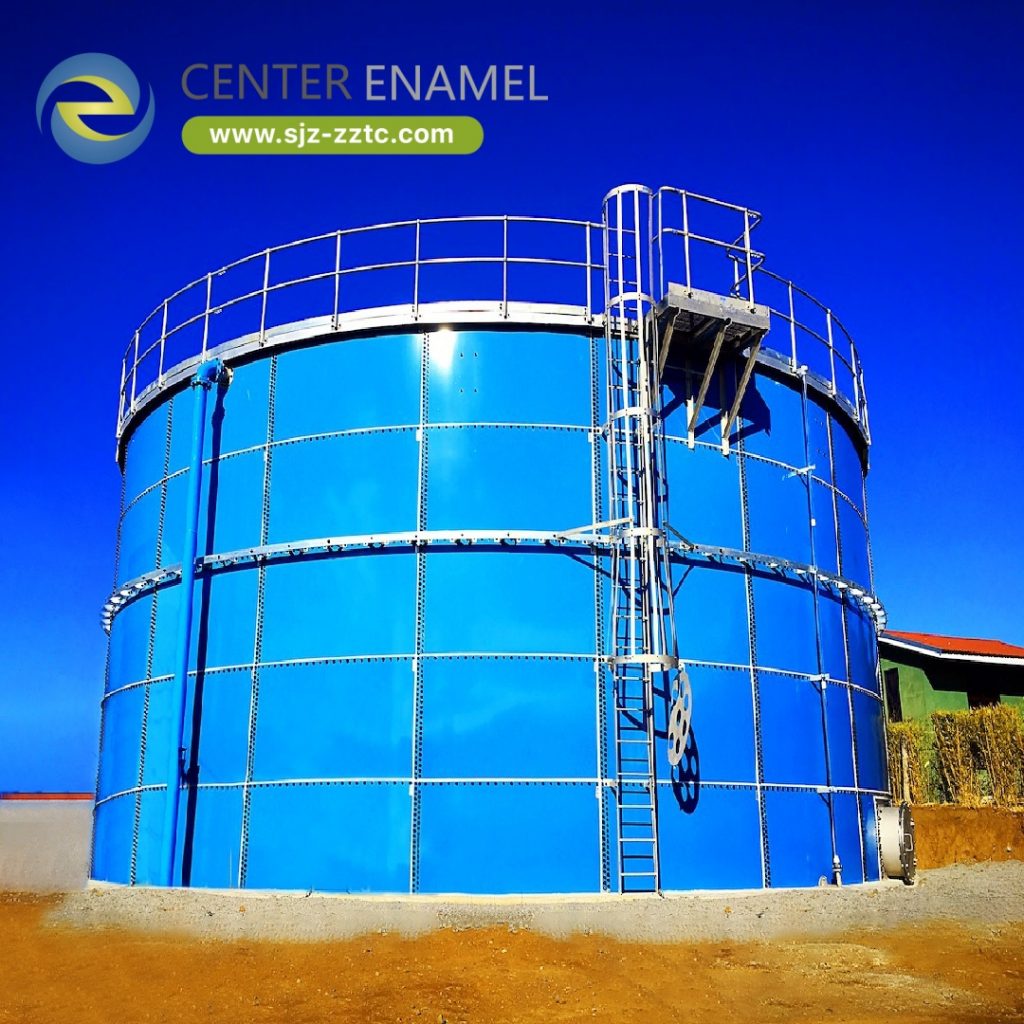

By employing our specialized, chemically inert Glass-Fused-to-Steel (GFS) digester tanks, Center Enamel enables food processors to achieve two critical goals: superior environmental compliance and comprehensive energy self-sufficiency, transforming the cost center of wastewater treatment into a profitable, sustainable asset.

The Imperative of Organic Waste Conversion in Food Processing

Successful Food Processing Wastewater Projects must address the highly variable and concentrated nature of effluent streams while meeting stringent health and environmental standards.

1. High Organic Load and Treatability

Food processing wastewater is perfectly suited for Biomass Electricity Generation due to its composition:

Extreme Chemical Oxygen Demand (COD): Effluent from breweries, dairies, and distilleries often contains massive biodegradable organic loads (starches, sugars, proteins, fats). This high COD concentration is the very fuel that makes anaerobic digestion, and subsequent biomass electricity generation, highly efficient and economically viable.

Variable Flow and Load: The volume and concentration of wastewater often fluctuate dramatically based on production cycles (e.g., batch processing, seasonal harvests). The treatment system must be robust, resilient, and capable of handling rapid changes in organic loading without compromising the stability of the biogas production process.

Nutrient Imbalance: While rich in carbon, some food streams may require pre-treatment or co-digestion to balance nutrient levels and optimize the microbial environment necessary for efficient methane production.

2. Operational and Economic Drivers

The move toward Biomass Electricity Generation is driven by both cost and sustainability requirements:

Energy Cost Volatility: Food processing is energy-intensive, requiring power for heating, cooling, pumping, and fermentation control. Generating power directly from wastewater insulates the facility from rising and volatile energy costs, ensuring long-term operational stability.

Environmental Compliance: Strict local and national regulations govern the discharge of Food Processing Wastewater Projects. High-efficiency anaerobic systems effectively destroy up to 90% of the organic load (COD), ensuring that downstream aerobic treatment steps are minimized and discharge limits are met.

Odor and Emission Control: Enclosed anaerobic digesters capture methane, a potent greenhouse gas that would otherwise escape from open ponds. This control dramatically reduces the facility's carbon footprint and eliminates the odor issues associated with uncontrolled organic decomposition.

The Technology: Anaerobic Digestion for Biomass Electricity Generation

The transition from waste to power is facilitated by high-rate anaerobic digestion, the engine that drives Biomass Electricity Generation within Food Processing Wastewater Projects. This biological process is inherently suited to liquid, high-strength organic waste.

1. The Biogas Production Loop

The core value chain of Biomass Electricity Generation involves two main steps:

High-Rate Methane Production: Specialized reactor technologies, such as the Upflow Anaerobic Sludge Blanket (UASB) or Expanded Granular Sludge Bed (EGSB), are employed to treat the high-load food wastewater. These systems retain a high concentration of granular sludge (microbes) that rapidly consume the high COD, efficiently converting it into methane-rich biogas at high volumetric loading rates.

Electricity Generation: The captured biogas is cleaned to remove contaminants like hydrogen sulfide, then fed directly into a Combined Heat and Power (CHP) unit or a dedicated engine. The CHP unit combusts the gas to generate electricity, which is used immediately on-site to power the plant, and simultaneously captures the waste heat for use in pasteurization, heating wash water, or maintaining the digester's optimal temperature. This co-generation maximizes the energy efficiency of the entire Food Processing Wastewater Project.

Footprint Reduction: High-rate anaerobic systems are compact, vertical structures that process far more wastewater per unit area than traditional lagoon systems, providing significant land-use savings for space-constrained industrial sites.

2. Digestate as a Valuable Resource

Beyond energy, anaerobic digestion produces a valuable effluent:

Nutrient Recovery: The final liquid digestate is a stable, nutrient-rich liquid. This can be used as a high-quality soil amendment or fertilizer, completing the circular economy loop by returning nutrients to agricultural land and reducing the need for chemical fertilizers.

Post-Treatment Efficiency: The significant destruction of COD in the anaerobic step dramatically reduces the energy and chemical input required for subsequent aerobic polishing steps, leading to overall lower operational costs for the Food Processing Wastewater Project.

GFS Tanks: The Foundation for Reliable Biomass Electricity Generation

For Food Processing Wastewater Projects, the integrity of the containment vessel is non-negotiable. It must operate reliably for decades, withstand the corrosive internal environment of the digester, and ensure the gas-tight capture of methane. Center Enamel’s Glass-Fused-to-Steel (GFS) tanks provide the ultimate foundation.

Unmatched Durability and Chemical Inertness

GFS technology offers the superior performance required for high-load industrial applications:

Corrosion Resistance for Biogas: Anaerobic digestion produces a corrosive environment rich in hydrogen sulfide and organic acids. The GFS coating, achieved by thermally fusing inert glass to high-strength steel, creates a permanent, non-porous chemical barrier. This protection guarantees the tank's longevity against internal corrosion, which is critical for maximizing the operational life of the Biomass Electricity Generation asset.

Structural Integrity and Safety: GFS tanks are engineered from high-strength steel panels, providing the structural stability necessary to safely contain large volumes and withstand the dynamic mixing forces inherent in high-rate reactors like UASB and EGSB.

Gas-Tight Methane Capture: The modular, bolted GFS design utilizes specialized sealants and precision fitting to ensure a superior, gas-tight enclosure. This is vital for maximizing the recovery of methane (the fuel for Biomass Electricity Generation) and ensuring safety and odor control on site.

Logistical and Economic Advantages

Center Enamel's GFS solution offers strategic benefits that align with the rapid expansion needs of the food sector:

Accelerated Project Deployment: GFS tanks are prefabricated and rapidly assembled on-site. This significantly reduces construction time compared to conventional concrete structures, allowing the Food Processing Wastewater Project to begin generating power and reducing costs much sooner.

Minimal Maintenance: The smooth, inert glass surface naturally resists sludge and residue buildup, minimizing the need for internal cleaning and reducing the long-term maintenance costs and associated operational downtime.

Global Compliance: The high quality and manufacturing standards of GFS tanks meet rigorous international environmental and safety certifications, providing peace of mind for global food corporations.

Project Cases

Center Enamel is a global leader in providing GFS containment for the food and industrial sector, facilitating high-efficiency anaerobic digestion and successful Biomass Electricity Generation across diverse Food Processing Wastewater Projects.

Sichuan Brewing Wastewater Treatment Project: This large-scale project involved providing GFS tanks for treating high-load brewing effluent, a classic example of food processing waste ideal for energy recovery. The installation consisted of 6 units with a total capacity of 14,648 cubic meters, showcasing our ability to deliver substantial multi-tank containment solutions for major beverage producers.

Jiangxiaobai Chongqing Jiangjin Distillery Wastewater Treatment Project: We supplied GFS containment for a complex distillery project, which involves extremely concentrated organic wastewater perfect for Biomass Electricity Generation. This installation involved 12 units with a total capacity of 10,606 cubic meters, affirming our expertise in executing multi-unit systems for high-concentration industrial Food Processing Wastewater Projects.

Shanxi Yuncheng Food Waste Treatment Project: We provided robust containment for a dedicated food waste and effluent processing facility, emphasizing the conversion of solid and liquid food organic matter into biogas. This project consisted of 5 units with a total capacity of 9,410 cubic meters, demonstrating our proven track record in supplying foundational infrastructure for biogas production from diversified food-based feedstocks.

Conclusion: Sustainability and Profitability in Harmony

For every Food Processing Wastewater Project, integrating Biomass Electricity Generation offers the most powerful pathway to sustainability. It transforms the challenging high COD effluent into a reliable, renewable energy source that directly powers the operation.

By choosing Center Enamel’s Glass-Fused-to-Steel (GFS) tanks, food processors secure the most durable, chemically resistant, and cost-effective containment solution available. This infrastructure is the guaranteed foundation for high-rate anaerobic digestion, ensuring maximized methane recovery, minimal environmental footprint, and long-term energy independence. Partner with us to turn your effluent into electricity and achieve a self-sufficient, economically resilient future for your food processing operations.