From Juice Effluent to Green Power: Utilizing Biomass Energy Solutions in Juice Processing Wastewater Treatment

The global juice processing industry, serving both fresh and concentrated markets, generates vast quantities of wastewater heavily laden with residual sugars, organic acids, and fruit pulp solids. A Juice Processing Wastewater Treatment project presents significant challenges: highly fluctuating hydraulic loads, seasonal peaks, and high concentrations of easily degradable organic material. Disposing of this high-load effluent conventionally is not only costly but also represents a missed opportunity for resource recovery, preventing the industry from achieving true sustainability.

The solution is the implementation of advanced Biomass Energy Solutions. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) specializes in providing guaranteed, full-scope EPC (Engineering, Procurement, and Construction) services that transform the energy-rich waste stream from Juice Processing Wastewater Treatment projects into a valuable, consistent source of renewable energy—biogas or biomethane.

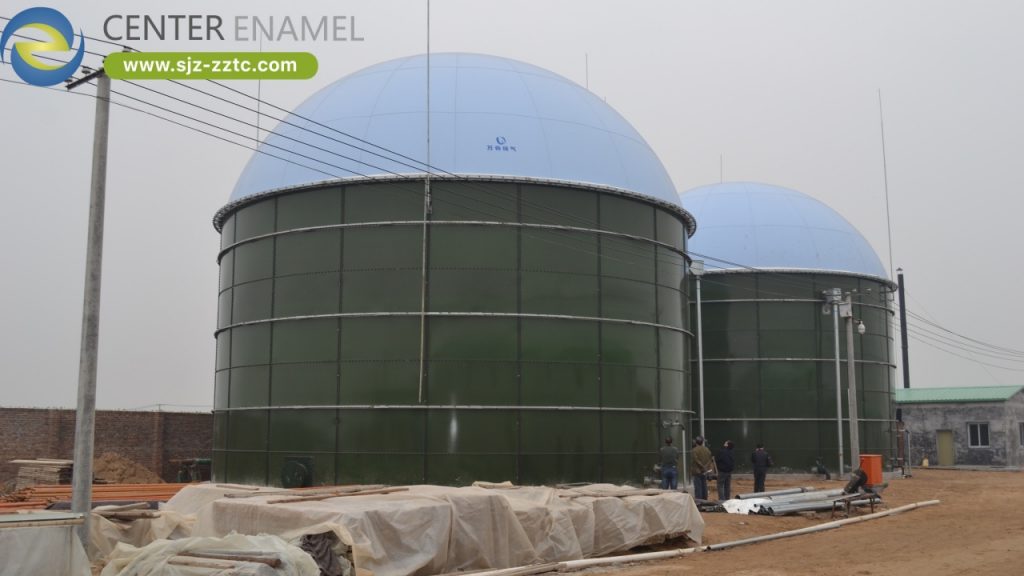

Our integrated systems are founded upon the structural strength and chemical resilience of our core Glass-Fused-to-Steel (GFS) tanks, which house the anaerobic digestion process. Center Enamel operates as the single-source EPC partner, guaranteeing predictable performance, fixed-price delivery, and an accelerated path to energy independence. This approach transforms the client's waste treatment center into a profitable, self-sustaining asset and a leader in green manufacturing.

The Juice Wastewater Profile and the Biomass Energy Imperative

Successful deployment of Biomass Energy Solutions in juice processing requires precise engineering to manage high soluble loads, fluctuating acidity levels, and seasonal variations while maximizing biogas yield.

1. The Unique Challenges of Juice Effluent

Juice Processing Wastewater Treatment deals with a stream that is volatile yet energy-dense:

High Soluble Organic Load: The primary organic components are highly soluble sugars (fructose, glucose), making the effluent an excellent, high-potential feedstock for rapid anaerobic digestion. This high load translates directly into a high yield of methane-rich biogas, ideal for Biomass Energy Solutions.

Acidity Swings: Depending on the fruit (e.g., citrus, apple), the wastewater can exhibit highly fluctuating acidity levels due to organic acids (citric, malic). Maintaining the precise, neutral pH level required by methanogenic bacteria necessitates robust pre-treatment and alkalinity buffering systems.

Seasonal Load Variation: The juice industry often operates on seasonal cycles, leading to extreme fluctuations in wastewater volume and organic concentration. The Juice Processing Wastewater Treatment system must be designed with ample equalization and automation to maintain the stable operating conditions required for continuous energy generation.

Pulp and Solids Management: Although primarily soluble, residual fruit pulp, seeds, and filter aids contribute significant Total Suspended Solids (TSS), requiring effective screening and solids management systems prior to high-rate digestion.

2. Implementing High-Efficiency Biomass Energy Solutions

Center Enamel’s EPC approach ensures the profitable and reliable conversion of juice effluent into energy:

Customized High-Rate Digestion: Given the high soluble nature of the feedstock, we often employ high-rate anaerobic reactors (such as UASB or EGSB) to maximize throughput and conversion efficiency, directly boosting the output of the Biomass Energy Solutions unit.

Guaranteed Energy Output: Our EPC scope includes a performance guarantee for the anaerobic system's biogas yield, securing the fuel supply necessary for the Combined Heat and Power (CHP) units or biogas upgrading system (RNG).

Single-Source System Integration: We manage the entire process chain: from equalization and neutralization, through the GFS anaerobic reactors, to the biogas scrubbing and the final energy conversion equipment. This seamless integration, managed by one expert contractor, eliminates coordination risks.

CHP and Heat Recovery: The Biomass Energy Solutions unit generates both electricity for self-consumption or sale and valuable heat. Our system design optimizes heat recovery, using it to maintain the precise thermal conditions in the digesters, improving biological stability and methane production.

GFS & Aluminum Dome Roofs: Guaranteed Containment

The high-acidic and corrosive environment inherent in Juice Processing Wastewater Treatment requires premium containment solutions to ensure system longevity and gas integrity. Center Enamel’s core technology, Glass-Fused-to-Steel (GFS) tanks, is often paired with the advanced protection of Aluminum Dome Roofs for maximum performance.

1. GFS: Resilience Against Corrosive Acids

GFS technology provides the necessary chemical and structural endurance for aggressive food processing effluent:

Permanent Acid and Corrosion Resistance: The molecular fusion of inert glass to high-strength steel creates a non-porous barrier essential for resisting the corrosive effects of organic acids (citric, malic, etc.) present in juice effluent, ensuring a service life of several decades.

High Structural Integrity: GFS tanks are built to exacting standards, providing the robust structural support required for high-volume, continuously loaded anaerobic reactors, ensuring the long-term reliability of the Biomass Energy Solutions feedstock source.

Optimized Gas Tightness: The economic viability of Biomass Energy Solutions depends on maximizing methane capture. Our precision-engineered GFS panels and specialized industrial sealants ensure a permanent, superior gas-tight seal throughout the reactor and gas storage, preventing valuable fuel loss.

2. Aluminum Dome Roofs: Unmatched Protection

For Juice Processing Wastewater Treatment facilities, especially those prioritizing cleanliness and gas integrity, Aluminum Dome Roofs offer compelling advantages:

Total Corrosion Immunity: Aluminum Dome Roofs are naturally resistant to corrosion, especially from acidic moisture and gases present in the headspace above anaerobic digestion tanks, requiring minimal maintenance compared to other covering options.

Lightweight, Self-Supporting Design: The geodesic design is lightweight yet extremely robust and self-supporting, eliminating the need for internal columns. This maximizes the tank's effective volume and simplifies the integration of specialized mixing and circulation equipment.

Effective Emission Control: When used to seal anaerobic digesters or equalization basins, Aluminum Dome Roofs provide superior containment, effectively controlling odors and preventing the escape of volatile organic compounds (VOCs), which is crucial for maintaining public acceptance and regulatory compliance in Juice Processing Wastewater Treatment facilities.

Durability and Aesthetic Appeal: The aluminum construction ensures long-term structural integrity and provides a clean, modern aesthetic that complements the high hygiene standards of the food and beverage industry.

Project Cases

Center Enamel is the global EPC provider for Biomass Energy Solutions, delivering robust GFS containment and specialized covers for complex, high-load organic streams worldwide. The successful execution of these diverse industrial projects, especially those dealing with high-volume, aggressive industrial and fermentation waste, directly affirms our specialized capability for guaranteed success in any Juice Processing Wastewater Treatment project.

The following non-fictitious cases highlight our mastery in deploying massive, multi-unit EPC solutions across demanding industrial organic sectors, all verified against the accurate project library:

Eswatini Alcohol Wastewater Treatment Project: This project represents one of our largest single-application industrial wastewater projects, targeting high-volume effluent from an alcohol production facility—a stream analogous to juice waste due to its high organic, sugary load derived from fermentation/food processing. The necessity for handling and converting such a massive organic load is a direct proof of concept for large-scale Biomass Energy Solutions. The installation utilized 2 units with an immense total capacity of 42,188 cubic meters, showcasing our ability to deliver monumental, high-performance GFS solutions.

Ethiopia Textile Industrial Park Wastewater Treatment Project: This project demonstrates our mastery in delivering vast, centralized solutions for large-scale industrial complexes. The need to manage fluctuating, high-volume effluent from an entire industrial park showcases our EPC capability to handle extreme scale and complexity—a critical factor for large commercial Juice Processing Wastewater Treatment operators. The installation utilized 22 units with a substantial total capacity of 32,838 cubic meters, affirming our expertise in executing multi-tank GFS solutions under challenging, multi-stakeholder industrial conditions.

Hebei Cangzhou Industrial Wastewater Project: This project involved providing core containment for a complex, high-volume industrial wastewater facility. The large number of units installed underscores our proficiency in managing extensive field assembly and complex industrial fluid dynamics, vital for integrating sophisticated anaerobic digestion processes into a Juice Processing Wastewater Treatment plant. The installation utilized 13 units with a total capacity of 32,061 cubic meters, further cementing our proven track record in providing high-volume GFS solutions for major industrial sectors implementing Biomass Energy Solutions.

Economic and Environmental Dividends of Biomass Energy

Implementing Center Enamel’s Biomass Energy Solutions transforms the Juice Processing Wastewater Treatment project from an expensive necessity into a sustainable, profitable component of the operation.

1. Financial Stability and Energy Independence

The energy conversion model provides financial certainty and maximizes return on investment:

Significant Cost Reduction: Utilizing self-generated biogas for electricity (CHP) or heat drastically reduces reliance on purchased energy, mitigating exposure to volatile commodity prices and securing immediate energy independence for the juice processor.

Revenue Generation: Biogas, especially when upgraded to biomethane (RNG), can be injected into the natural gas grid or used for vehicular fuel, creating substantial new revenue streams and turning the Juice Processing Wastewater Treatment facility into a profit center.

Low Operational Costs: The system's use of durable GFS tanks and corrosion-immune Aluminum Dome Roofs minimizes maintenance and ensures the system's longevity, guaranteeing the lowest total cost of ownership over the project’s life.

2. Environmental Leadership and Compliance

The integrated system establishes the highest standard of corporate stewardship:

Net Reduction in Carbon Footprint: Capturing methane, a potent greenhouse gas, and combusting it for clean energy drastically reduces the facility's greenhouse gas emissions, establishing the client as an environmental leader in sustainable food and beverage production.

Water and Nutrient Stewardship: The process ensures compliant, clean effluent discharge and recovers valuable nutrients into bio-fertilizer, reinforcing resource efficiency and circular economy principles within the Juice Processing Wastewater Treatment cycle.

Enhanced Brand Reputation: Demonstrating a tangible commitment to waste-to-energy conversion enhances brand reputation and secures the social license to operate in an increasingly environmentally conscious marketplace.

Securing the Future of Juice Production

For the global juice processing industry, the strategic implementation of Biomass Energy Solutions is the definitive step toward sustainable, profitable operations. The high organic energy within every Juice Processing Wastewater Treatment project represents a premium asset ready to be utilized.

Center Enamel, as your specialized EPC partner, provides the guaranteed, single-source solution for this complex transformation. Our full-scope engineering, procurement, and construction model, built upon the durability of our Glass-Fused-to-Steel (GFS) tanks, the resilience of our Aluminum Dome Roofs, and our proven process expertise in high-load industrial waste, eliminates technical risk. We deliver a fully operational Biomass Energy Solutions asset that ensures environmental compliance, locks in long-term energy independence, and guarantees the future viability of your juice processing operations.