Full-Scope Biogas to Energy EPC Solutions for Brewing Wastewater Management

The global brewing industry—a sector defined by high-quality production and massive volumes—faces a persistent, dual challenge: managing vast quantities of nutrient-rich wastewater and controlling significant operational energy costs. Brewing Wastewater Management demands more than simple compliance; it requires an innovative strategy to transform a liability into a sustainable asset.

Brewery effluent, containing high concentrations of sugars, yeast residues, and spent grains, represents an exceptionally potent source of untapped energy. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) offers the definitive solution through comprehensive, single-point Biogas to Energy EPC Solutions. We manage the entire project lifecycle, from initial concept and engineering to construction and commissioning, delivering a turnkey waste-to-power facility that secures energy self-sufficiency.

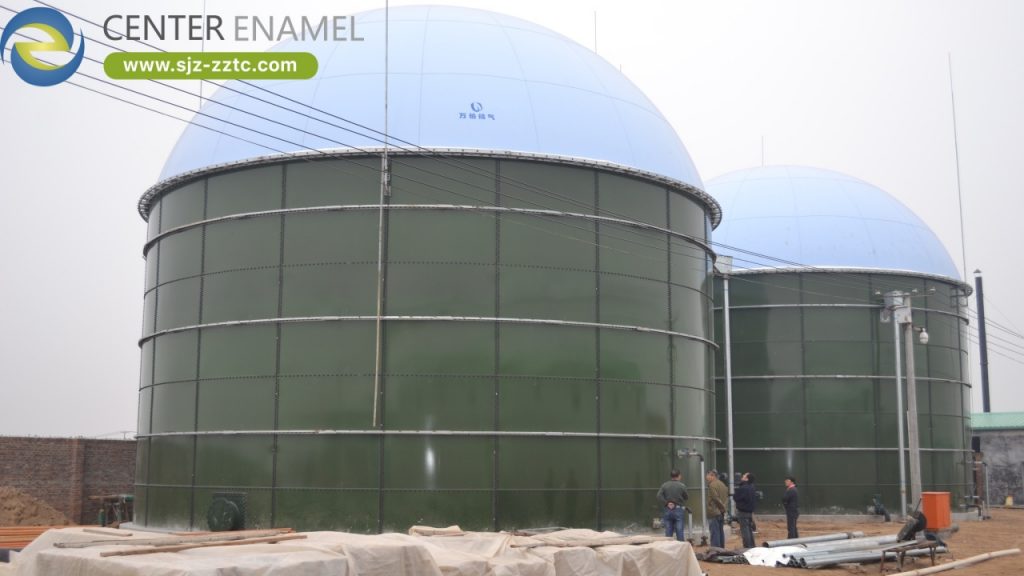

Our solutions are founded on the superior, corrosion-resistant containment provided by our Glass-Fused-to-Steel (GFS) tanks, which serve as the core of the high-rate anaerobic digester. By selecting Center Enamel for your Biogas to Energy EPC Solutions, breweries secure a guaranteed, fixed-price project that minimizes execution risk, achieves world-class Brewing Wastewater Management, and establishes a profound competitive advantage through sustainable energy generation.

The Brewery Effluent Profile and the EPC Strategy

Successful Brewing Wastewater Management hinges on recognizing the effluent's high organic value and designing a system that can stably handle its fluctuating characteristics. This complexity necessitates the expertise of an experienced EPC provider.

1. The Volatile Nature of Brewing Wastewater

Brewery wastewater (BWW) is an ideal, high-yield feedstock for anaerobic digestion, but presents specific design challenges:

High Organic Load and Biogas Potential: BWW contains high concentrations of readily degradable compounds like sugars and ethanol, leading to exceptionally high Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD). This high energy density translates directly into maximum methane-rich biogas yield.

Flow and Load Variability: Wastewater generation is highly dependent on batch schedules, brewing cycles, and daily washdowns. Flow rates and organic concentrations can fluctuate significantly. The chosen Biogas to Energy EPC Solutions must incorporate robust homogenization and balancing systems to ensure the digester receives a stable, optimized feedstock, maintaining microbial health.

Temperature Management: BWW is often discharged at high temperatures, which must be carefully managed. The Biogas to Energy EPC Solutions design utilizes the GFS containment structure to support efficient heat recovery and transfer systems, maintaining the optimal thermophilic or mesophilic temperatures required for fast, efficient digestion.

pH Swings: Cleaning processes often introduce wastewater with extreme acidity levels or alkalinity. The EPC design must include effective pH buffering mechanisms to protect the anaerobic microbes and maintain stable process conditions.

2. Why Comprehensive EPC Solutions are Essential

A Biogas to Energy EPC Solutions for brewing wastewater is a highly technical integration of multiple subsystems. Relying on a single, accountable provider like Center Enamel is the only way to minimize project risk:

Guaranteed Energy Output: The EPC contract guarantees the final power and heat generation capacity, providing the brewery with clear financial certainty and a predictable Return on Investment (ROI). We assume the risk of process integration.

Seamless Technology Integration: The project involves linking pre-treatment (screening, fat removal), high-rate digestion, biogas purification (carbon dioxide and sulfide removal), and the Combined Heat and Power (CHP) unit. Center Enamel ensures all these components are perfectly sized and integrated through a single technical standard.

Fixed Cost, Fixed Schedule: Our Biogas to Energy EPC Solutions provide a firm, fixed budget and an accelerated construction timeline, preventing costly schedule slips and overruns often associated with multi-vendor projects.

Total Compliance: We ensure the final treated effluent meets or exceeds all local discharge standards, resolving the brewery’s compliance issues while simultaneously generating energy.

Technical Excellence: GFS Containment for Biogas Systems

The long-term success of any Biogas to Energy EPC Solutions is dependent on the durability and integrity of the anaerobic reactor—the GFS tank.

1. GFS Tanks: Engineered for Aggressive Effluent

The decomposition of brewing waste creates a highly corrosive internal environment. GFS provides the ultimate defense:

Permanent Corrosion Resistance: Anaerobic digestion of BWW generates corrosive organic acids and hydrogen sulfide gas. The molecularly fused glass layer on our GFS panels creates a non-porous, permanent chemical barrier that offers superior corrosion resistance compared to standard steel or concrete, guaranteeing the integrity of the Brewing Wastewater Management system for decades.

Optimized Gas-Tight Seal: Capturing every unit of methane is critical for profitability. Our precision-engineered GFS tanks, assembled with specialized industrial sealants, ensure a permanent, superior gas-tight seal, maximizing the recovery of the valuable fuel.

Structural Reliability for High Volumes: Brewing Wastewater Management requires massive reactor volumes. GFS tanks are structurally engineered with high-strength steel to withstand the immense hydrostatic loads and the dynamic forces from powerful internal mixing systems necessary to process high-solids BWW.

2. High-Rate Reactor Integration

Center Enamel's Biogas to Energy EPC Solutions incorporate the most efficient reactor technology for brewery waste:

UASB (Upflow Anaerobic Sludge Blanket) or IC (Internal Circulation): These reactors are ideal for the soluble, high-concentration organic load of BWW, providing a smaller physical footprint and faster retention times, maximizing the efficiency of the Biogas to Energy EPC Solutions.

Integrated Heat Management: The EPC design includes heat exchange coils and insulation integrated into the GFS containment structure, allowing the Biogas Power Plant to use its own generated heat (from the CHP unit) to maintain optimal digester temperatures, creating a highly efficient, closed-loop thermal system.

The Operational Advantages of an EPC Partnership

Choosing Center Enamel for Biogas to Energy EPC Solutions provides substantial operational and economic benefits for Brewing Wastewater Management.

1. Superior Operational Efficiency

The GFS tank combined with our process engineering leads to streamlined operations:

Minimal Maintenance: The smooth, inert glass surface resists the build-up of yeast residues and scaling, minimizing downtime and reducing the need for costly internal cleaning or maintenance interventions.

Fast Project Realization: The modular, prefabricated nature of GFS tanks allows for rapid on-site assembly by our certified teams, drastically reducing construction timelines and enabling the brewery to start generating power and achieving cost savings much sooner.

Long-Term Asset Value: The permanence of the GFS coating eliminates the high recurring costs associated with repainting or relining conventional tanks, locking in lower operating expenditure for the Biogas to Energy EPC Solutions.

2. Financial and Environmental Stewardship

The EPC approach provides financial security and reinforces environmental commitments:

Reduced Financial Risk: Our single, fixed-price contract for the entire Biogas to Energy EPC Solutions removes the financial uncertainty associated with cost overruns, material price volatility, and unforeseen construction complications.

Circular Economy Leadership: By converting wastewater into energy and generating clean water and nutrient-rich fertilizer (digestate), the brewery establishes a closed-loop system, reinforcing its commitment to sustainability and reducing its overall carbon footprint.

Scalability and Future-Proofing: The modular GFS design allows for easy and cost-effective capacity expansion, ensuring the Brewing Wastewater Management system can adapt to future increases in production or changes in regulatory requirements.

Project Cases

Center Enamel is the global leader in providing comprehensive Biogas to Energy EPC Solutions, offering the robust GFS containment necessary to manage high-load, complex organic waste streams across industries. Although the following projects are anchored in livestock breeding, their technical demands—managing high organic concentrations, fluctuating loads, and the need for reliable energy recovery—directly mirror the challenges and success required for advanced Brewing Wastewater Management.

These flagship projects demonstrate our capacity to execute multi-unit, high-capacity EPC solutions for aggressive, high-concentration organic effluent:

Muyuan Group Jiangsu Suqian Breeding Wastewater Project: This project required highly durable GFS containment to manage the continuous, high-strength organic effluent from a major livestock breeding operation. The successful execution demonstrated our specialized ability in designing a stable, high-rate anaerobic process—a core requirement for efficient Brewing Wastewater Management—and delivering a reliable Biogas to Energy EPC Solutions. The installation featured 2 units with a substantial total capacity of 7,429 cubic meters, affirming our expertise in high-volume, multi-reactor solutions.

Guangxi Nanning Pig Breeding Project: This project involved supplying core containment infrastructure for managing pig breeding wastewater, a waste stream characterized by high organic and solids content. The need for robust, corrosion-resistant containment and reliable gas capture aligns perfectly with the technical demands of brewery digestion. We supplied 2 units with a total capacity of 7,429 cubic meters, showcasing our mastery in engineering high-capacity GFS systems for aggressive, high-BOD effluent.

Muyuan Group Jiangsu Breeding Wastewater Treatment Project: This initiative required a specialized containment system to ensure the long-term, stable treatment of high-volume breeding wastewater, focusing on maximizing organic removal and resource recovery. The project affirmed our proven track record in executing multi-tank, large-capacity EPC solutions that deliver superior longevity and stable process reliability under challenging organic loads. The installation comprised 2 units with a total capacity of 7,158 cubic meters, further cementing our capability to support large-scale industrial-grade waste-to-energy projects.

Conclusion: Brewing a Sustainable Future

For the brewing industry, the pursuit of energy independence and environmental compliance converges in one solution: the Biogas to Energy EPC Solutions. This model transforms the high-BOD effluent from Brewing Wastewater Management into a consistent, self-generated source of power and heat.

Center Enamel’s comprehensive Biogas to Energy EPC Solutions, underpinned by the unmatched durability and chemical resilience of our Glass-Fused-to-Steel (GFS) tanks, offers the beverage sector a guaranteed partnership. We eliminate project risk, accelerate execution, and deliver a fully operational asset that secures long-term sustainability and a powerful competitive edge.