Green Fuel Projects: Harnessing Biogas Technology for Industrial Sustainability

The global industrial sector is currently at a critical crossroads. As international regulations tighten and the volatility of fossil fuel markets increases, the transition toward decentralized, renewable energy has become a prerequisite for long-term operational viability. Central to this transition are Green Fuel Projects—industrial-scale initiatives that utilize advanced Biogas Technology to transform organic byproducts into a reliable, carbon-neutral energy stream. By capturing methane that would otherwise escape into the atmosphere, these projects provide a dual benefit: they mitigate potent greenhouse gas emissions while simultaneously securing a low-cost, on-site fuel source for power, heat, or transport.

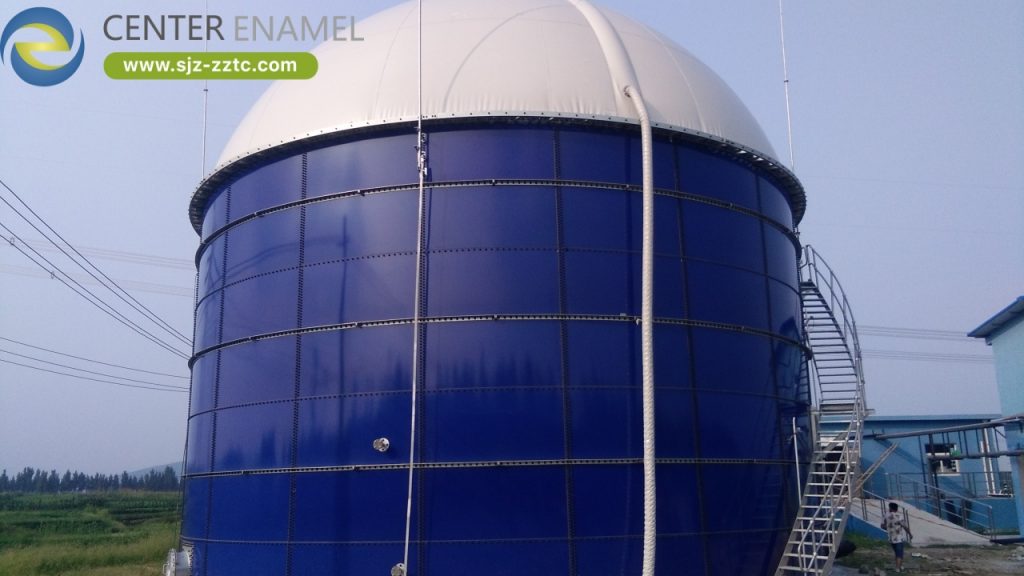

Shijiazhuang Zhengzhong Technology Co., Ltd, operating under the world-renowned brand Center Enamel, stands as a global leader in providing the specialized engineering infrastructure necessary for this transition. With over thirty years of innovation and a project footprint extending to more than one hundred countries, we provide the turnkey containment and processing solutions that make high-efficiency biological recovery a reality. Our expertise lies in the integration of Glass-Fused-to-Steel (GFS) technology, high-performance Epoxy Coated Tanks, and advanced Double Membrane Roofs, creating a cohesive platform designed to maximize the reliability and energy output of industrial biogas systems.

Technical Foundations of Industrial Biogas Technology

To deliver effective Green Fuel Projects, it is essential to understand the biological and mechanical parameters that define high-performance anaerobic digestion. Biogas Technology is the controlled microbial breakdown of organic matter in the absence of oxygen, resulting in a gas mixture primarily composed of methane and carbon dioxide.

1. Process Optimization and Energy Recovery

Modern Biogas Technology focuses on maximizing the "Specific Methane Yield" from diverse feedstocks. Whether processing food waste, agricultural residues, or municipal sludge, the reactor must maintain a stable environment for methanogenic bacteria. Center Enamel’s EPC services ensure that every project is engineered with precise thermal management and mixing systems, allowing for the continuous production of biogas that can be utilized in Combined Heat and Power (CHP) units or upgraded into biomethane for grid injection.

2. Feedstock Versatility in Green Fuel Projects

The success of industrial Green Fuel Projects depends on the ability to handle fluctuating feedstock qualities. Our systems are engineered to process:

Food and Beverage Waste: High-energy liquids and solids from industrial processing.

Agricultural Slurries: Consistent waste streams from large-scale livestock operations.

Municipal Sludge: Residual solids from wastewater treatment facilities.

Core Technology: The Double Membrane Roof System

In any successful application of Biogas Technology, the efficient capture and pressure regulation of the produced gas are the most critical factors for achieving industrial sustainability. Center Enamel’s Double Membrane Roofs are engineered as a dynamic, integrated gas management solution.

1. Advanced Structural Mechanics and Dual-Layer Architecture

The Double Membrane Roof is a sophisticated pressurized system consisting of two high-specification membranes working in synergy:

The Inner Membrane: This layer serves as the primary seal for the anaerobic digestion process. It is in direct contact with the biogas. Its flexible nature allows it to expand and contract freely based on real-time gas volume, ensuring the reactor maintains a consistent internal pressure.

The Outer Membrane: This layer is constantly pressurized by an automated blower system. It forms a rigid, permanent aerodynamic dome that protects the inner storage membrane from external environmental forces, such as wind pressure, heavy rainfall, and snow accumulation.

2. Material Science and Gas Integrity

Industrial biogas is often humid and contains corrosive vapors. Our membranes are manufactured from high-tenacity polyester fabrics with specialized multi-layer coatings:

Gas Permeability Resistance: The inner membrane features a specialized coating that minimizes gas loss, ensuring every cubic meter of fuel is captured.

Industrial Corrosion Protection: The fabric is chemically inert, resisting the acidic vapors common in industrial anaerobic environments.

Environmental Durability: The outer membrane is UV-stabilized and features a self-cleaning surface, ensuring structural integrity across diverse global climates.

Containment Infrastructure: GFS and Epoxy Coated Tank Solutions

A successful Green Fuel Project requires containment that can handle the aggressive nature of organic waste and the physical demands of continuous industrial operation.

1. Glass-Fused-to-Steel (GFS) Technology: The Premier Choice

Our flagship GFS tanks are the global benchmark for the core anaerobic reactor. By fusing high-tech glass enamel to specialized steel at temperatures exceeding eight hundred degrees, we create a material with unparalleled properties:

Superior Chemical Resistance: The glass interior is completely impervious to the organic acids and corrosive gases generated during digestion.

Rapid Modular Construction: The bolted design allows for significantly faster installation times compared to traditional concrete, which is vital for industrial facilities looking to minimize disruption.

2. Epoxy Coated Tanks: High-Performance Industrial Storage

As a critical part of our infrastructure portfolio, Center Enamel’s Epoxy Coated Tanks provide an excellent solution for various stages of the biogas treatment train.

Advanced Coating Technology: Our epoxy tanks utilize a high-specification electrostatic powder coating process. This results in a smooth, durable finish that provides excellent resistance against a wide range of industrial chemicals.

Versatile Application: These tanks are ideal for equalization, storage of treated digestate, or as buffer tanks within the facility. They offer a cost-effective yet highly durable alternative where high corrosion resistance is essential.

3. Aluminum Dome Roofs: Efficient Secondary Containment

For the storage of treated digestate or process water where gas capture is not the primary requirement, Center Enamel offers specialized Aluminum Dome Roofs . These self-supporting geodesic structures are used for odor control and to prevent rainwater ingress. Constructed from high-strength aluminum alloy, they are naturally resistant to corrosion and require no internal support columns, providing a maintenance-free solution for secondary storage.

Sustainability and Economic ROI for Industry

Implementing advanced Biogas Technology through Center Enamel’s EPC services is a strategic economic decision for any modern industrial facility:

Energy Recovery and Cost Offset: By generating power on-site, industries can significantly reduce their reliance on expensive grid electricity and fossil fuels for process heating.

Waste Valorization and Savings: Anaerobic digestion reduces the mass of the waste stream, drastically lowering the costs associated with transport and final disposal.

ESG and Carbon Mitigation: Capturing methane allows companies to meet their sustainability targets and align with global Environmental, Social, and Governance (ESG) standards.

Global Project Excellence: Center Enamel in Action

Our expertise in providing containment for complex Green Fuel Projects is proven through successful installations:

Shandong Heze Biogas Project This major regional initiative utilized 3 units of our high-performance GFS tanks. The project successfully transforms concentrated organic residues into a stable energy stream, demonstrating the reliability of our integrated gas storage systems.

Inner Mongolia Hinggan League Bio-Natural Gas Project In a region characterized by extreme temperature fluctuations, this installation integrated 4 units of our bolted steel tanks. These vessels and their Double Membrane Roofs provide the stable environment necessary for the high-efficiency production of bio-natural gas, proving the resilience of our engineering against extreme snow loads.

Jiangsu Xuzhou Biogas Project This project involved the deployment of 4 units of our advanced containment technology. It serves as a model for how Center Enamel’s EPC services can be used to rapidly build essential infrastructure for modern industrial energy recovery.

Leading the Future of Industrial Energy

The implementation of advanced Biogas Technology within Green Fuel Projects represents a transformative step toward a more sustainable and resilient industrial energy landscape. By converting a byproduct into a renewable energy asset, facilities can protect their local environment while securing their energy future.

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are dedicated to providing the innovation and engineering excellence that make these projects a success. From our premier GFS tanks and high-performance Epoxy Coated Tanks to our specialized Double Membrane Roofs and Aluminum Dome Roofs, we offer a total containment solution designed for the future of industrial sustainability.