Isothermal CSTR Reactor Systems Optimized for Stable Biogas Production

In the realm of industrial and municipal wastewater treatment, Continuous Stirred Tank Reactors (CSTRs) play a pivotal role—especially in anaerobic digestion systems where consistent biogas production is essential. When paired with isothermal control systems, these reactors can maintain a constant operating temperature, thereby enhancing microbial activity and improving biogas yield. Center Enamel, a leading tank and wastewater treatment system manufacturer, offers high-performance isothermal CSTR reactors designed to provide stable biogas output and long-term operational reliability across diverse industries, including chemical processing, agriculture, and municipal waste treatment.

Advantages of Isothermal CSTR Reactors in Anaerobic Digestion

Isothermal CSTR systems offer a series of distinct advantages in biogas production processes, especially under the rigorous conditions of anaerobic digestion. Key benefits include:

Constant Temperature Control for Enhanced Microbial Efficiency: Anaerobic digestion depends heavily on maintaining optimal temperature ranges—typically mesophilic or thermophilic. Isothermal CSTR reactors ensure uniform thermal conditions throughout the tank, preventing hot or cold zones that can disrupt microbial metabolism.

Improved Process Stability and Biogas Yield: The steady environment maintained by isothermal systems allows microbial populations to flourish, accelerating organic breakdown and maximizing methane output. This is critical for applications where energy recovery through biogas is a primary goal.

Robust Mixing for Uniform Digestion: The continuous stirring mechanism of CSTRs ensures the homogeneous mixing of sludge, nutrients, and heat, which is further stabilized by the isothermal system. This promotes even digestion and reduces the risks of sedimentation or short-circuiting.

High Volatile Solids Reduction Rates: Effective temperature control supports higher volatile solids destruction, reducing the volume of residual sludge and enhancing the sustainability of the treatment process.

Flexible Design and Modular Expansion: Isothermal CSTR reactors can be scaled or customized according to project size and feedstock type. This makes them suitable for both small rural biogas plants and large industrial waste-to-energy projects.

Product Introduction

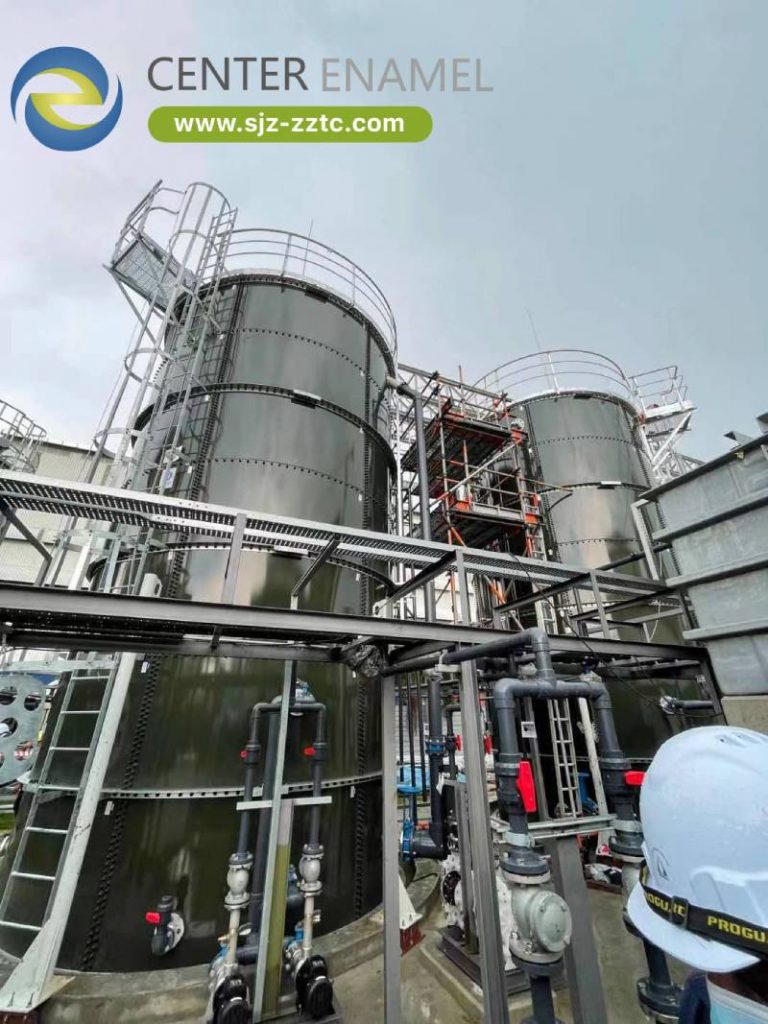

Center Enamel's isothermal CSTR systems are not just tanks; they are integrated, precision-engineered reactor systems. At the core is our highly durable Glass-Fused-to-Steel (GFS) tank. Fusing a glass enamel coating to steel at over 800°C creates an impermeable, inert barrier that provides maximum protection against the corrosive and acidic components of anaerobic digestion. The modular, bolted construction allows for rapid and safe on-site installation, significantly reducing project timelines and labor costs.

Our reactors are equipped with advanced thermal regulation systems, including external heat exchangers and precision control units, to maintain a constant internal temperature. This is complemented by robust mechanical mixing systems with optimized impeller designs to ensure a homogeneous environment and prevent dead zones. The entire system is built for longevity, minimal maintenance, and maximum efficiency in converting organic waste to biogas.

Why Center Enamel is the Ideal Partner for Isothermal CSTR Reactor Projects

With over 30 years of experience and a global footprint in wastewater treatment solutions, Center Enamel is uniquely positioned to deliver advanced isothermal CSTR reactors tailored to diverse operational needs.

Proven Expertise in Reactor Design and Fabrication: Our engineering team designs each reactor based on comprehensive feedstock analysis and project goals. From heat management systems to mechanical mixing and insulation, our isothermal CSTRs are precision-built for maximum performance.

World-Class Fusion-Bonded Epoxy and GFS Tank Systems: Our reactor tanks are constructed using industry-leading coatings, ensuring corrosion resistance, leak-proof integrity, and compliance with international quality standards.

Custom Solutions for Global Conditions: Whether the project is in a tropical climate or a cold, high-altitude region, our isothermal CSTR reactors are designed to adapt. Every component is tailored for site-specific performance.

Integrated Biogas and Energy Recovery Systems: We don’t just build tanks—we deliver complete solutions. Our isothermal CSTR systems can be integrated with CHP units, gas upgrading systems, or storage tanks, enabling full-circle energy recovery and sustainability.

Fast Assembly and Scalable Expansion: Modular design and bolted construction allow for rapid on-site installation with minimal labor. Our systems are easily expandable, allowing clients to scale operations without overhauling their infrastructure.

Comprehensive Technical Support and Lifecycle Services: From commissioning to after-sales service, Center Enamel offers full technical support. Our global network ensures that expertise is available where and when it’s needed.

Project Cases

Our expertise and product quality are demonstrated through our extensive portfolio of successful projects across the globe.

Hebei Municipal Water Project: For a municipal water project in Hebei, we provided a tank with a total capacity of 1,010 cubic meters. This project involved a durable tank solution to support the city's urban water infrastructure.

Muyuan Group Hubei Suizhou Livestock Wastewater Project: With 4 units totaling 10,750 cubic meters, this project highlights our expertise in treating large volumes of livestock wastewater.

Coca-Cola (Jiangsu) Beverage Wastewater Treatment Project: This project, with 2 units totaling 3,026 cubic meters, highlights our capability to deliver a tailored solution for a demanding public utility.

Inner Mongolia Dairy Wastewater Treatment Project: This project, with 1 unit totaling 1,162 cubic meters, showcases our ability to provide reliable solutions for the dairy industry.

Sichuan Brewing Wastewater Treatment Project: This project, comprising 6 units with a total capacity of 14,648 cubic meters, highlights our expertise in treating high-strength organic wastewater from a major beverage producer.

Hebei Starch Wastewater Treatment Project: This project, with 2 units totaling 3,380 cubic meters, showcases our ability to meet the rigorous demands of industrial wastewater management with a reliable solution.

By integrating isothermal control with advanced CSTR technology and durable tank construction, Center Enamel’s systems offer a high-efficiency, low-maintenance solution for stable and sustainable biogas production. These reactors are a powerful tool for governments, industries, and agricultural sectors seeking reliable waste-to-energy solutions within the chemical and environmental industries. Center Enamel remains committed to partnering with industries worldwide, delivering customized CSTR systems that not only solve waste management challenges but also build a cleaner, greener future for all.