Juice Beverage Wastewater: Utilizing Renewable Natural Gas Solutions for Waste-to-Energy Conversion

The global juice and beverage industry, driven by high consumer demand, faces a critical challenge in managing its effluent. Juice Beverage Wastewater Projects are characterized by high volumes of water, residual sugars, fruit pulp, and cleaning agents, resulting in an effluent with a high organic load and highly variable acidity levels. Discharging this wastewater without advanced treatment incurs significant operational costs, environmental fines, and reputational risk, severely hindering the goal of sustainable production.

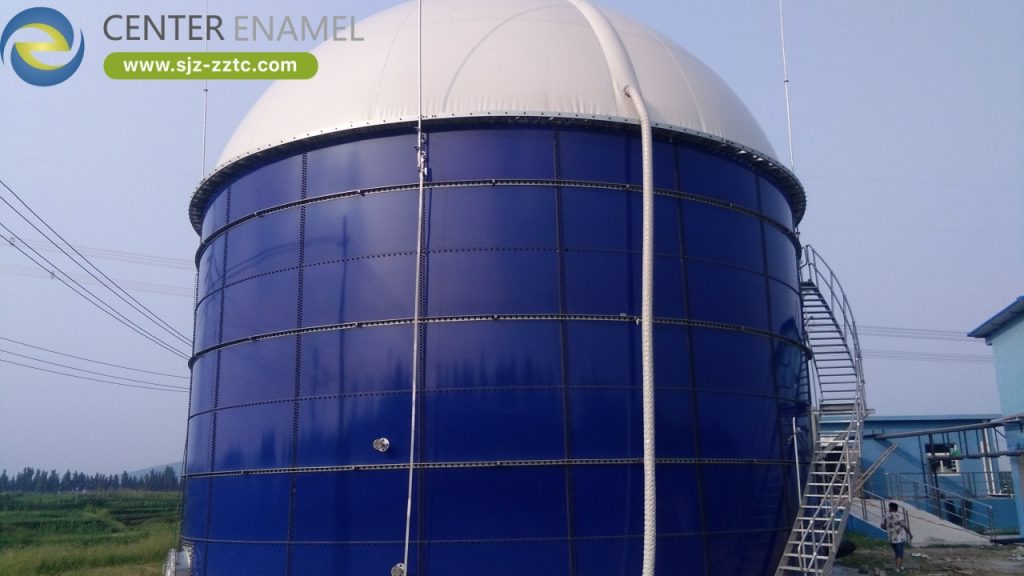

The modern imperative is to view this waste not as a liability, but as a robust source of energy. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) is the industry-leading provider of comprehensive Renewable Natural Gas Solutions. We offer end-to-end EPC services that transform highly polluting juice and beverage effluent into clean, high-value biogas and ultimately, pipeline-quality natural gas.

Our technology is founded on the unparalleled chemical resilience and reliability of our Glass-Fused-to-Steel (GFS) tanks. As your specialized EPC partner, Center Enamel takes full responsibility for the project, delivering a single-source, fixed-price solution that ensures environmental compliance, achieves maximum energy recovery, and secures long-term profitability for every Juice Beverage Wastewater Project.

The Beverage Wastewater Profile and the RNG Imperative

Successful implementation of Renewable Natural Gas Solutions in the beverage sector requires managing highly variable organic loads and ensuring stable anaerobic digestion.

1. Unique Characteristics of Juice Beverage Wastewater

Juice and beverage effluent presents a favorable, yet complex, feedstock for anaerobic digestion:

High Soluble Organic Load: The wastewater contains significant amounts of easily digestible sugars (glucose, fructose), starches, and organic acids. This results in extremely high Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD), which translates directly into a high potential for methane-rich biogas production.

Acidity Fluctuation: The cleaning and processing phases often lead to wastewater with rapid and significant shifts in acidity level—from the inherent acidity level of fruit juices to the high alkalinity of cleaning-in-place (CIP) solutions. The system must be engineered with advanced flow equalization and buffering capacity to protect the sensitive microbial environment of the anaerobic reactor.

Temperature and Volume: Beverage plants generate large, continuous volumes of wastewater, often discharged at temperatures that can stress the treatment system. The Juice Beverage Wastewater Project must be designed to manage this hydraulic and thermal load efficiently and consistently.

2. De-Risking the Project with Comprehensive EPC

Converting this complex stream into high-purity Renewable Natural Gas Solutions demands a multi-disciplinary, single-source approach:

Guaranteed Performance Metrics: Center Enamel guarantees the entire system's key performance indicators, including minimum biogas yield, methane concentration, and the final quality of the purified RNG. This shields the client from the technical and financial risks associated with integrating multiple technologies.

Seamless Process Integration: The entire system—including pre-treatment, GFS-based anaerobic reactors, biogas upgrading, and effluent polishing—must function as a unified asset. Our EPC model ensures seamless integration across all process, mechanical, and electrical disciplines, eliminating vendor conflicts and performance gaps.

Optimized RNG Upgrading: The EPC scope fully includes the gas upgrading unit (GUU) technology. This crucial step purifies the raw biogas by removing trace contaminants and carbon dioxide, ensuring the final product meets the stringent purity requirements for injection into the commercial gas grid or for use as Compressed Natural Gas (CNG).

Fixed Cost, Predictable Timeline: We provide a firm, fixed-price contract and an accelerated construction schedule. This is invaluable for Juice Beverage Wastewater Projects, as it removes budgetary uncertainty and accelerates the client's transition to energy self-sufficiency.

The GFS Foundation for High-Rate RNG Reactors

The operational lifespan and efficiency of any Renewable Natural Gas Solutions facility are rooted in the reliability of the anaerobic reactor vessel. Center Enamel's GFS tank technology provides the required structural and chemical resilience.

1. Engineered for Chemical and Thermal Endurance

Our GFS tanks provide the non-negotiable foundation for long-term operational success:

Superior Chemical Resistance: The decomposition of high-organic beverage waste generates corrosive organic acids and gaseous sulfur compounds. The molecular fusion of inert glass to high-strength steel creates a non-porous, permanent, inert barrier that resists these aggressive compounds, guaranteeing the reactor's structural integrity for decades of operation.

Optimal Gas Capture: Maximum methane recovery is essential for economic viability. The precision-engineered GFS panels and specialized industrial sealants ensure a permanent, superior gas-tight seal at every seam, optimizing the input for the Renewable Natural Gas Solutions purification process.

Rapid, Modular Installation: The prefabricated, bolt-together nature of GFS panels drastically reduces on-site construction time compared to concrete, minimizing disruption to ongoing beverage production and accelerating the system's path to energy generation.

2. EPC Design for High-Rate Beverage Digestion

As the specialized EPC contractor, we tailor the process to manage the soluble, high-energy beverage effluent:

High-Rate Reactor Selection: For Juice Beverage Wastewater Projects, we often employ highly efficient anaerobic technologies like Upflow Anaerobic Sludge Blanket (UASB), which maximize organic removal in a small footprint and are ideally suited for soluble organic waste like sugars.

Automated Buffering and Dosing: Critical to managing the volatile acidity levels of beverage waste, our EPC design integrates automated systems to monitor and adjust the acidity level and alkalinity, maintaining the stable environment required for the methanogenic bacteria.

Effluent Polishing Integration: Beyond anaerobic digestion, our scope includes post-treatment polishing steps (e.g., aerobic treatment, filtration) to ensure the final effluent meets the most stringent discharge standards for color and residual contaminants.

Project Cases

Center Enamel is the global EPC provider for Renewable Natural Gas Solutions, delivering robust GFS containment for complex, high-load organic streams worldwide. The scale and complexity of these projects, particularly those related to the food and beverage sectors, directly affirm our specialized capability for guaranteed success in any Juice Beverage Wastewater Project.

The following cases highlight our mastery in deploying multi-unit, high-capacity EPC solutions across demanding food and beverage industrial sectors:

Coca-Cola Company Malaysia Factory Wastewater Treatment Project: This project for a major global beverage producer required highly specialized GFS containment and process design to treat continuous, high-volume effluent from a large-scale factory. The successful execution demonstrated our ability to deliver reliable, international-standard Renewable Natural Gas Solutions for the beverage industry. The installation utilized 2 units with a total capacity of 1,905 cubic meters, showcasing our expertise in delivering efficient, high-performance systems for demanding global brands.

Mengniu Group Heilongjiang Dairy Product Wastewater Treatment Project: This project involved providing a robust GFS containment solution to manage dairy wastewater, a stream characterized by high organic (lactose, proteins) content that aligns with the high-load nature of a Juice Beverage Wastewater Project. The necessity for durable, corrosion-resistant tanks for continuous high-rate anaerobic digestion was paramount. The facility comprised 1 unit with a substantial total capacity of 1,078 cubic meters, affirming our capability to provide tailored, high-volume solutions for the food processing sector.

Guangdong Dairy Product Wastewater Treatment Project: This multi-unit project required providing core containment infrastructure for continuous, high-load dairy wastewater processing in a key agricultural region. The successful delivery of the tanks for this Renewable Natural Gas Solutions-enabling process showcases our mastery in executing multi-tank GFS solutions that provide superior longevity and process reliability under aggressive organic loading. The installation featured 3 units with a total capacity of 1,032 cubic meters, further cementing our proven track record in the demanding food and beverage treatment landscape.

Conclusion: Seizing the RNG Advantage

For the juice and beverage industry, adopting a comprehensive Renewable Natural Gas Solutions model is the most effective strategy for environmental stewardship and economic viability. The high organic content of a Juice Beverage Wastewater Project is a valuable energy asset waiting to be harnessed.

Center Enamel, as your specialized EPC partner, provides the single-source, guaranteed solution for this transformation. Our full-scope EPC model, built upon the durability and chemical resilience of our Glass-Fused-to-Steel (GFS) tanks, eliminates technical risk and delivers a fully operational RNG asset. This solution not only ensures regulatory compliance but also locks in long-term energy independence, minimizes the carbon footprint, and secures the future sustainability of your beverage operations.