Palm Oil Wastewater Treatment Project (POME): Full-Scope EPC Service for Biogas Power Plant Development

The global palm oil industry is a massive engine of agricultural production, but its success generates a unique and profound environmental challenge: Palm Oil Mill Effluent (POME). POME is a hot, acidic, high-volume wastewater characterized by an extremely high organic load. Historically managed through massive open lagoons, POME decomposition results in the uncontrolled release of methane—a potent greenhouse gas—and poses severe risks to local water quality.

The modern mandate for the palm oil sector is clear: convert this immense organic liability into a sustainable energy asset. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) offers the definitive solution through a complete, single-point EPC Service for Biogas Power Plants integrated into the Palm Oil Wastewater Treatment Project. We take full responsibility for the project, delivering a seamless transition from wastewater management to energy self-sufficiency.

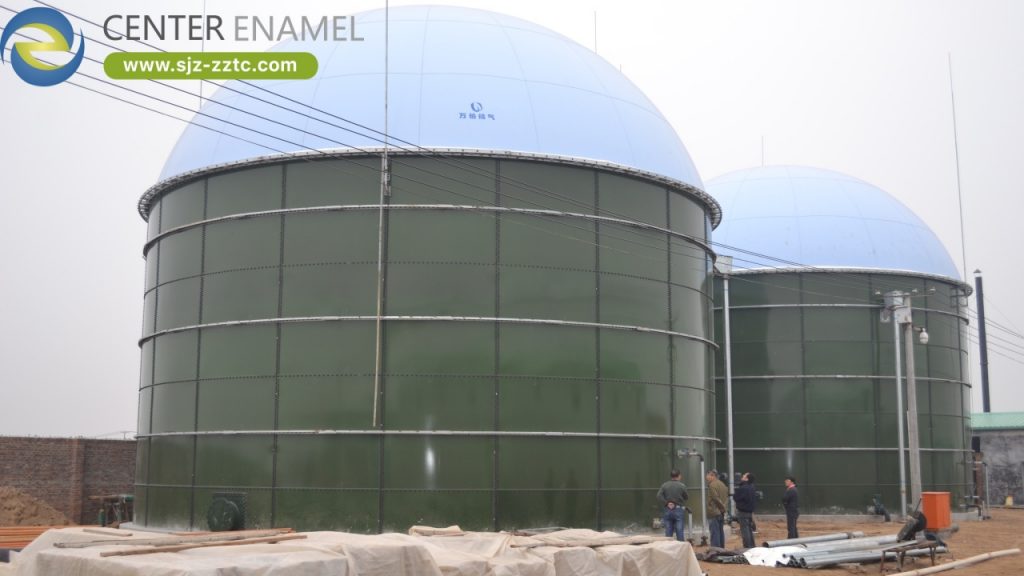

Our solution is engineered around the unparalleled durability and chemical resistance of our Glass-Fused-to-Steel (GFS) tanks, which serve as the core containment for high-rate anaerobic digestion. By selecting Center Enamel's comprehensive EPC Service for Biogas Power Plants, palm oil mills achieve guaranteed environmental compliance, eliminate methane emissions, and secure long-term, reliable energy for their operations with maximum efficiency and minimal execution risk.

The POME Challenge and the Strategic EPC Solution

Palm Oil Wastewater Treatment Project implementation is technically complex due to POME's unique composition. This complexity makes a comprehensive EPC Service for Biogas Power Plants an essential de-risking strategy for mill operators.

1. The Aggressive Nature of POME Effluent

Palm Oil Mill Effluent (POME) is one of the most challenging industrial wastes to manage:

Extreme Organic Load: POME contains residual oil, sugars, and organic solids, resulting in exceptionally high Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD). This high energy density translates directly into the highest potential yield of methane-rich biogas per unit volume among industrial wastes.

High Temperature and Acidity: POME is typically discharged at high temperatures and often has a high acidity level. These characteristics require specialized materials and robust process control within the Biogas Power Plant to maintain the stability necessary for microbial activity.

High Solids and Slurry Viscosity: The effluent is a dense, high-solids slurry requiring specialized pumping and mixing systems within the reactor. The containment structure must be built to withstand the immense hydrostatic loads and the mechanical forces exerted by these powerful agitators.

Methane Emissions: In traditional open pond systems, the natural anaerobic breakdown of POME releases vast, uncontrolled quantities of methane, a severe environmental violation. The Palm Oil Wastewater Treatment Project must be fully enclosed to capture this valuable gas.

2. Why EPC Service is Crucial for POME Biogas Plants

The complexity of handling POME, integrating multiple technologies, and operating in remote locations demands a single, accountable contractor:

Guaranteed Performance and Output: Our EPC Service for Biogas Power Plants guarantees the final power generation capacity and the POME treatment efficiency. We absorb the technical integration risk, ensuring the mill receives a fully operational, high-performing asset.

Seamless Integration and Coordination: A POME biogas facility involves feedstock cooling, pre-treatment, anaerobic digestion, biogas cleaning, and power generation (CHP). Center Enamel ensures all these subsystems—including the core GFS tanks, heat exchangers, gas holders, and power unit—are perfectly designed and integrated through a single technical standard.

Accelerated Project Timeline: Managing Engineering, Procurement, and Construction through one dedicated team eliminates the logistical conflicts and communication delays inherent in multi-vendor projects, drastically reducing the time required to achieve energy self-sufficiency for the Palm Oil Wastewater Treatment Project.

Fixed Budget and Cost Certainty: The EPC contract provides the mill operator with a fixed budget, shielding them from cost overruns and unexpected procurement or construction challenges that frequently plague complex industrial projects.

Technical Solution: GFS Containment at the Heart of the Biogas Plant

The long-term viability of the Palm Oil Wastewater Treatment Project depends on the resilience of the anaerobic reactor. Center Enamel’s GFS tanks provide the definitive containment solution.

1. Engineering for High-Rate POME Digestion

Our EPC Service for Biogas Power Plants designs the system around the most efficient anaerobic reactor technology for POME:

High-Rate CSTR or UASB: Continuous Stirred Tank Reactors (CSTR) or Upflow Anaerobic Sludge Blanket (UASB) reactors are typically chosen for their ability to handle the continuous flow and high organic load of POME.

Pre-Treatment Integration: The EPC design includes the necessary equipment for cooling the hot POME and potentially segregating residual oil and solids, ensuring the feedstock enters the digester at the optimal temperature and consistency for maximum methane yield.

GFS Integrity: Our GFS tanks provide the necessary high-strength containment for these massive, high-rate reactors. The structure is designed to withstand the immense hydraulic load of the POME slurry and the significant mechanical forces from the powerful mixers.

2. The GFS Corrosion Barrier

The greatest threat to a POME digester is corrosion. The GFS tank provides a permanent defense:

Permanent Chemical Resistance: The anaerobic decomposition of POME generates high levels of corrosive organic acids and hydrogen sulfide gas. The molecularly fused glass layer on our GFS panels creates an impervious, non-porous chemical barrier that offers corrosion resistance superior to standard coated steel and concrete, guaranteeing a lifespan of many decades.

Gas-Tight Safety and Efficiency: The safe and profitable capture of methane is paramount. The precision manufacturing of GFS components, combined with specialized industrial sealants, ensures a permanent, superior gas-tight seal at every seam, maximizing energy recovery and fulfilling safety requirements for the Biogas Power Plant.

The Center Enamel GFS Advantage

Choosing Center Enamel’s GFS technology as the core reactor containment provides strategic, long-term operational advantages for any Palm Oil Wastewater Treatment Project.

1. Durability and Minimal Maintenance

GFS tanks are built for the demanding equatorial environments where palm oil mills operate:

Reduced Lifetime Costs: The inert nature of the glass coating eliminates the need for expensive repainting, relining, or major maintenance associated with corrosion, drastically lowering the operating expense of the Biogas Power Plant.

Anti-Adhesive Surface: The smooth, glass interior surface resists the buildup of residual oil, sludge, and scale common in POME treatment, minimizing downtime and the need for costly manual cleaning interventions.

Built-in Flexibility: The modular, bolted design allows for future capacity expansion by adding ring sections, ensuring the Palm Oil Wastewater Treatment Project can scale with the mill's production capacity.

2. EPC Execution Excellence

Our single-source EPC Service for Biogas Power Plants ensures project quality from start to finish:

Global Logistics and Installation: We manage the entire supply chain, including international shipping of the prefabricated GFS components to often remote mill locations, and utilize specialized, certified installation teams for rapid, guaranteed assembly.

Process Optimization: We don't just build tanks; we deliver a process. The EPC service guarantees that the digester and the downstream CHP unit are optimized for the specific characteristics of the mill's POME, maximizing the efficiency of the Biogas Power Plant.

Training and Commissioning: We finalize the project by ensuring all systems are running optimally and providing comprehensive training to local mill staff, transferring the knowledge necessary for safe, independent operation.

Project Cases

Center Enamel's robust GFS containment forms the essential infrastructure delivered through our comprehensive EPC Service for Biogas Power Plants. This ensures the guaranteed success of complex, high-load industrial and organic waste-to-energy projects globally, mirroring the demanding requirements of a Palm Oil Wastewater Treatment Project.

The following case studies demonstrate our ability to execute critical containment and process solutions in high-strength organic effluent management:

Muyuan Group Guangxi Laibin Livestock Wastewater Treatment Project: This project highlights our capacity to manage challenging, high-concentration organic waste streams typical of the animal farming industry, which demands absolute structural and gas-tight integrity. The installation involved 2 units with a total capacity of 1,908 cubic meters, showcasing our expertise in designing and supplying multi-unit systems crucial for continuous and stable biogas power generation.

Anhui Ma'anshan Industrial Wastewater Project: As part of a major industrial facility upgrade, we provided the core reactor containment through our single-source EPC approach. This project utilized 1 unit with an impressive total capacity of 1,700 cubic meters, demonstrating our proven capability to deliver substantial, customized containment solutions for aggressive industrial wastewater treatment and efficient energy recovery.

Muyuan Group Hunan Changsha Livestock Wastewater Treatment Project: We supplied the reliable GFS containment for this significant organic waste-to-energy conversion system. This installation featured 1 unit with a capacity of 1,600 cubic meters, affirming the proven durability and performance of our GFS technology in large-scale anaerobic digestion systems, ensuring long-term operational resilience for power generation initiatives.

Conclusion: Guaranteeing Success in Palm Oil Sustainability

The integration of a waste-to-energy solution is the defining feature of a sustainable Palm Oil Wastewater Treatment Project. By embracing a Biogas Power Plant, palm oil mills transform their largest environmental liability—POME—into reliable, renewable electricity and heat.

Center Enamel’s comprehensive EPC Service for Biogas Power Plants, anchored by the unmatched durability and chemical resilience of our Glass-Fused-to-Steel (GFS) tanks, offers the palm oil industry a single-point solution for guaranteed project success. We remove the technical complexity, manage the execution risk, and deliver a fully operational asset that ensures energy independence and environmental stewardship for decades to come.