Sustainable Poultry Operations: Utilizing Biomethane Solutions for Chicken Meat Processing Wastewater

The poultry processing industry, a crucial link in the global food supply chain, generates wastewater that is notoriously challenging to treat. Chicken Meat Processing Wastewater (CMPWW) is characterized by high levels of blood, fat, protein, and suspended solids. This results in effluent with an extremely high organic load, posing significant challenges for conventional disposal, leading to escalating costs, potential environmental contamination, and difficulties in achieving strict regulatory compliance.

The paradigm shift in modern processing is centered on circularity and resource recovery. Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) specializes in delivering guaranteed Biomethane Solutions. We offer end-to-end EPC (Engineering, Procurement, and Construction) services that transform the pollutant-rich effluent from Chicken Meat Processing Wastewater projects into high-purity, pipeline-quality biomethane (Renewable Natural Gas, or RNG).

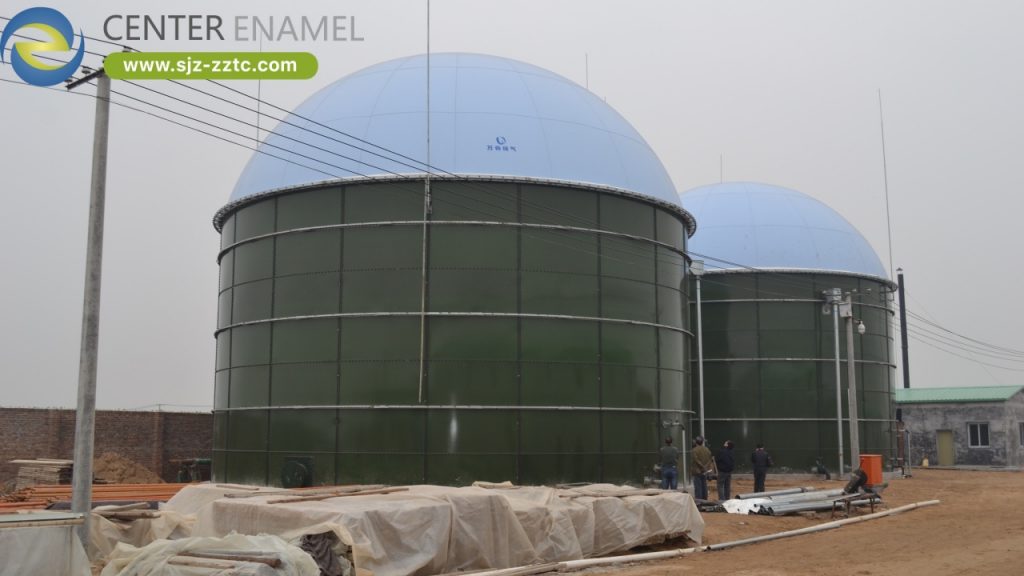

Our reliable performance systems are built upon the structural integrity and chemical resilience of our core Glass-Fused-to-Steel (GFS) tanks. Center Enamel serves as the single-source EPC contractor, providing predictable, fixed-price delivery that ensures regulatory compliance, maximizes energy output, and secures long-term economic stability for the client's operations.

The CMPWW Challenge and the Biomethane Imperative

Successfully deploying Biomethane Solutions for CMPWW requires precise engineering to manage fat, oil, grease (FOG), and high protein concentrations while maximizing methane yield.

1. The Aggressive Profile of Chicken Meat Processing Wastewater

CMPWW is comparable to general slaughterhouse waste but often features specific characteristics that impact digestion:

High Protein and Fat Content: The effluent is rich in dissolved and suspended proteins (blood) and fats. While fats offer high methane potential, they are difficult to digest and can lead to scum layer formation if not properly pre-treated and mixed.

High Suspended Solids and Load Variability: Processing involves batch cleaning and washdowns, resulting in high concentrations of Total Suspended Solids (TSS) and fluctuating organic load. Robust pre-treatment and equalization are essential to prevent system upsets and ensure the stability required for Biomethane Solutions.

Odour and Pathogen Risk: The high protein and blood content create immediate odour challenges and potential pathogen risks. Anaerobic digestion within gas-tight GFS reactors effectively stabilizes the organic material, eliminating the odor source and reducing pathogen levels significantly, addressing critical concerns for Chicken Meat Processing Wastewater projects.

High Energy Potential: The extremely high organic load (COD/BOD) found in CMPWW makes it an ideal, high-potential feedstock for anaerobic conversion, directly supporting the economics of Biomethane Solutions.

2. Why Biomethane Solutions Require an EPC Partner

The profitable conversion of complex CMPWW into purified biomethane (RNG) demands expert integration and guaranteed performance managed by a single contractor:

Single-Source Accountability: Center Enamel assumes total technical and financial risk for the entire system, from initial FOG removal to the final gas upgrading unit. This eliminates performance gaps and coordination conflicts common when managing multiple vendors in Chicken Meat Processing Wastewater projects.

Guaranteed RNG Quality: Our EPC scope includes the guarantee that the final biomethane product meets the stringent quality specifications required for commercial sale or utilization (e.g., pipeline injection or CNG vehicle fuel).

FOG and Solids Management Expertise: We design and integrate specialized pre-treatment, separation (e.g., DAF), and enhanced mixing systems to effectively manage the high FOG and solids content, ensuring optimal reactor performance and preventing system downtime.

Fixed Cost and Predictable Delivery: We provide a firm, fixed-price contract and an accelerated construction schedule. This is crucial for maintaining operational continuity in the poultry processing sector while transitioning to a profitable Biomethane Solutions platform.

GFS Containment: The Foundation for High-Protein Digestion

The high-stress, corrosive environment created by the digestion of high-protein and fat-rich Chicken Meat Processing Wastewater demands the most durable containment available. Center Enamel’s Glass-Fused-to-Steel (GFS) tank technology provides the required structural and chemical resilience.

1. Engineered for Aggressive Environments

Our GFS tanks ensure maximum reactor uptime and longevity in demanding applications:

Superior Corrosion Resistance: The digestion of high-protein waste creates corrosive hydrogen sulfide gas and organic acids. The molecular fusion of inert glass to high-strength steel provides a permanent, non-porous barrier that resists these aggressive chemicals, securing the structural integrity of the digester shell for decades.

Optimal Gas-Tight Integrity: For profitable Biomethane Solutions, maximum gas capture is essential. Our precision-engineered GFS panels and advanced sealing systems ensure a permanent, superior gas-tight seal at every joint, optimizing the collection and transfer of methane to the upgrading unit.

Resistance to FOG and Solids: The smooth, durable GFS surface is highly effective in resisting the adherence of FOG and heavy solids, facilitating cleaning and complementing the efficiency of the integrated mixing systems necessary for Chicken Meat Processing Wastewater treatment.

2. EPC Reactor Design for High-Protein Feedstock

Center Enamel’s EPC approach customizes the anaerobic process for the specific characteristics of CMPWW:

Reactor Technology Selection: We typically deploy technologies like Continuous Stirred-Tank Reactors (CSTR) or other high-rate designs suitable for the high Total Solids (TS) and viscosity of the pre-treated poultry effluent, ensuring high conversion efficiency.

Integrated Heat and FOG Management: Our design integrates the GFS tanks with heat exchangers to maintain optimal thermophilic or mesophilic temperatures. Crucially, the EPC scope includes specialized mixing technology to continuously emulsify and circulate FOG, maximizing its availability for methane generation while preventing scum layer formation.

Process Stability and Control: Sophisticated automation systems monitor and control key process parameters, including acidity level and temperature, ensuring the biological stability required for consistent biogas supply to the Biomethane Solutions upgrading unit.

Project Cases

Center Enamel is the global EPC provider for high-value Biomethane Solutions, delivering robust GFS containment for complex, high-load industrial organic streams worldwide. The scale and complexity of these projects, particularly those related to industrial processing and high-volume organic waste, directly affirm our specialized capability for guaranteed success in any demanding Chicken Meat Processing Wastewater project.

The following cases highlight our mastery in deploying multi-unit, high-capacity EPC solutions across demanding industrial organic sectors:

Fujian Industrial Wastewater Treatment Project: This large-scale industrial project required supplying core containment infrastructure for a complex, high-volume wastewater facility managing continuous organic flows. The successful delivery of this high-capacity solution showcases our capability to handle the substantial volume and chemical complexity required for a large-scale Chicken Meat Processing Wastewater facility. The installation utilized 2 units with a substantial total capacity of 7,508 cubic meters, affirming our expertise in executing high-capacity GFS solutions for major industrial clients.

Zhejiang Shaoxing Chemical Wastewater Treatment Project: This complex industrial project required robust GFS containment and process design to manage highly aggressive chemical wastewater. This experience in handling chemically challenging loads is directly transferable to managing the corrosive nature of biogas and the variable composition of Chicken Meat Processing Wastewater. The facility comprised 2 units with a total capacity of 6,499 cubic meters, demonstrating our mastery in deploying multi-tank GFS systems for chemically complex and demanding industrial environments.

Guangdong Huizhou Industrial Park Wastewater Treatment Project: This project involved providing core containment infrastructure for continuous, high-volume industrial wastewater processing within a major park. The necessity for durable, corrosion-resistant tanks to maintain process stability under aggressive organic and hydraulic loads was critical. The installation featured 1 unit with a substantial capacity of 4,614 cubic meters, further cementing our proven track record in providing high-performance, large-volume GFS solutions that enable reliable Biomethane Solutions across diverse industrial sectors.

The Economic and Environmental Dividends of Biomethane

Implementing Center Enamel’s Biomethane Solutions transforms the Chicken Meat Processing Wastewater project from a significant operational cost into a long-term profit center and a cornerstone of corporate sustainability.

1. Superior Financial Performance and Energy Security

The conversion of CMPWW into biomethane provides unmatched financial stability:

Revenue Generation and Monetization: High-purity biomethane can be injected into the natural gas grid or sold as Compressed Natural Gas (CNG), generating substantial new, stable revenue streams and maximizing the value of the waste resource.

Energy Independence: By generating high-quality RNG, the poultry processing plant gains insulation from volatile commercial energy prices, significantly reducing operating expenditures and securing long-term energy supply.

Carbon Reduction Incentives: Biomethane, as a form of renewable natural gas, qualifies for environmental credits, carbon offsets, and regulatory incentives in many global jurisdictions, providing an additional layer of financial return on the Chicken Meat Processing Wastewater investment.

2. Environmental Leadership and Compliance

The integrated Biomethane Solutions model ensures the highest standards of environmental stewardship:

Greenhouse Gas Mitigation: Capturing methane, a potent greenhouse gas, from the effluent stream and utilizing it as fuel drastically reduces the facility's carbon footprint, establishing the client as a leader in clean food manufacturing.

Water Resource Protection: The system guarantees that the final treated effluent meets or exceeds all local and international discharge standards, protecting sensitive water sources from the detrimental effects of high-COD and pathogen-laden wastewater.

Circular Economy Principle: The process fully recovers both energy (biomethane) and valuable nutrients (digestate bio-fertilizer), ensuring that the waste product is completely recycled back into the agricultural or energy system, fulfilling the core principles of a circular economy.

Securing the Future of Poultry Processing

For the poultry meat processing industry, the strategic adoption of Biomethane Solutions is the definitive step toward sustainable, profitable operations. The immense organic energy within every Chicken Meat Processing Wastewater project represents a premium asset ready to be utilized.

Center Enamel, as your specialized EPC partner, provides the guaranteed, single-source solution for this complex transformation. Our full-scope engineering, procurement, and construction model, built upon the durability and chemical resilience of our Glass-Fused-to-Steel (GFS) tanks, eliminates technical risk, particularly the challenges posed by high FOG and protein content. We deliver a fully operational, high-purity biomethane asset that ensures regulatory compliance, locks in long-term energy independence, and guarantees the future viability of your poultry operations.