The Strategic Integration of Various Biomass Feedstock into Modern Waste-to-Energy Projects via Biogas Energy Technology

In the current era of industrial decarbonization, the definition of "waste" has undergone a fundamental shift. No longer viewed simply as a liability for disposal, organic residues are now recognized as one of the most stable and dispatchable sources of renewable power available. However, the true potential of Waste-to-Energy Projects is only realized when they can effectively handle the complexity of a diversified supply chain. The strategic integration of various biomass streams—ranging from agricultural residues and food waste to municipal sludge—requires a sophisticated application of Biogas Energy Technology. To succeed, these projects must balance the biological variability of mixed feedstocks with industrial-grade containment and gas management infrastructure.

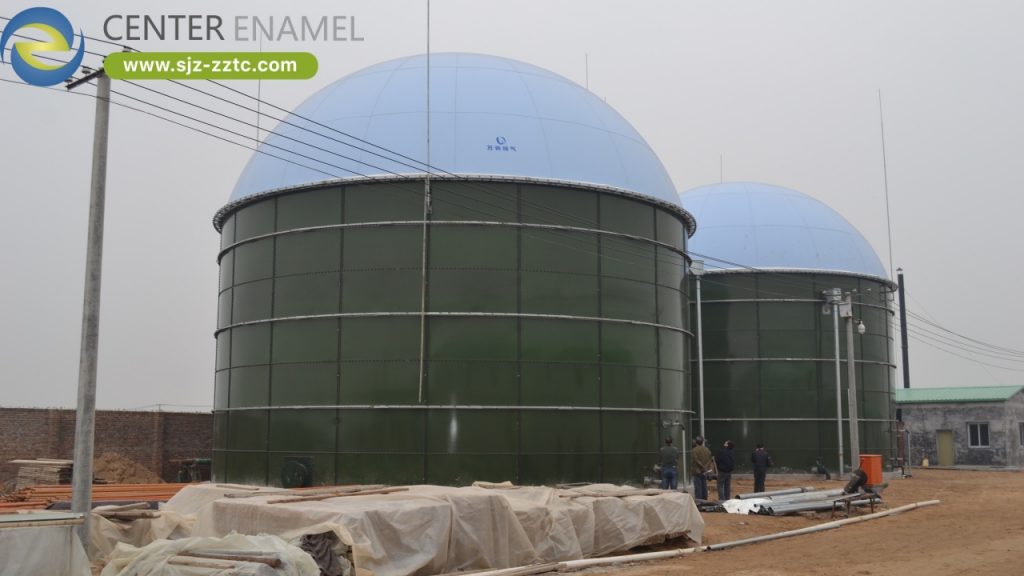

Shijiazhuang Zhengzhong Technology Co., Ltd, operating under the world-renowned brand Center Enamel, stands as a global pioneer in providing the specialized engineering necessary for this transition. With over thirty years of innovation and a project footprint extending to more than one hundred countries, we provide the turnkey containment and processing solutions that make high-efficiency biological recovery a reality. Our expertise lies in the integration of Glass-Fused-to-Steel (GFS) technology, high-performance Epoxy Coated Tanks, and advanced Double Membrane Roofs, creating a cohesive system designed to transform diverse biomass into a consistent stream of sustainable energy.

Technical Foundations of Biomass Integration in Waste-to-Energy Projects

To optimize Waste-to-Energy Projects, it is essential to understand the biological synergy created by co-digesting different organic streams. Biogas Energy Technology thrives on nutrient balance, and the integration of diverse feedstocks provides a more robust environment for methanogenic microorganisms.

1. Co-Digestion and Biological Synergy

Single-source feedstocks often suffer from nutrient deficiencies or chemical imbalances (such as excessive nitrogen in poultry manure or high acidity in food waste). By integrating various biomass types, a Waste-to-Energy Project can achieve:

Carbon-to-Nitrogen Balance: Combining high-carbon agricultural residues (like straw or corn stover) with nitrogen-rich animal slurries ensures optimal microbial health.

Process Buffering: Certain wastes, like cattle manure, have high alkalinity which helps stabilize the pH levels of the entire system when processing more volatile acidic wastes like fruit and vegetable residues.

Increased Gas Yield: Co-digestion has been proven to increase the specific methane yield by up to 20% compared to mono-digestion, directly improving the ROI of the facility.

2. Managing Physical Heterogeneity

Integrating "various" biomass means dealing with different textures, moisture levels, and densities. Center Enamel’s EPC services prioritize advanced pre-treatment and mixing systems. Our reactors are designed to handle both "wet" and "semi-solid" digestion processes, ensuring that whether the facility is processing liquid pig slurry or baled energy crops, the material is fully homogenized for maximum contact between the bacteria and the organic matter.

Core Technology: The Double Membrane Roof System

In any sophisticated Waste-to-Energy Project, the efficient capture, storage, and pressure regulation of the produced biogas are the most critical factors for long-term industrial sustainability. Center Enamel’s Double Membrane Roofs are engineered as a dynamic, integrated gas management solution.

1. Advanced Structural Mechanics and Dual-Layer Architecture

The Double Membrane Roof is a sophisticated pressurized system consisting of two high-specification membranes working in synergy:

The Inner Membrane: This layer serves as the primary seal for the anaerobic digestion process. It is in direct contact with the biogas produced from the integrated biomass. Its flexible nature allows it to expand and contract freely based on real-time gas volume, ensuring the reactor maintains a consistent internal pressure.

The Outer Membrane: This layer is constantly pressurized by an automated blower system. It forms a rigid, permanent aerodynamic dome that protects the inner storage membrane from external environmental forces, such as wind pressure, heavy rainfall, and snow accumulation.

2. Material Science and Gas Integrity

Biogas derived from mixed waste streams can be highly complex and corrosive. Our membranes are manufactured from high-tenacity polyester fabrics with specialized multi-layer coatings:

Gas Permeability Resistance: The inner membrane features a specialized coating that minimizes gas loss, ensuring every cubic meter of fuel is captured for utilization.

Environmental Durability: The outer membrane is UV-stabilized and features a self-cleaning surface, ensuring structural integrity across diverse global climates.

3. EPC Integration: Intelligent Safety and Pressure Control

As part of our Biogas Energy Technology solutions, Center Enamel integrates a comprehensive suite of monitoring devices:

Automated Air Management: Sensors monitor the air pressure between the membranes, and the blower system adjusts automatically to maintain optimal tension.

Volume Monitoring: High-precision sensors track the height of the inner membrane, providing real-time data on gas storage levels to the facility’s central command system.

Containment Infrastructure: GFS and Epoxy Coated Tank Solutions

A successful Waste-to-Energy Project requires containment that can handle the aggressive nature of diverse organic waste and the physical demands of continuous industrial operation.

1. Glass-Fused-to-Steel (GFS) Technology: The Premier Choice

Our flagship GFS tanks are the global benchmark for the core anaerobic reactor. By fusing high-tech glass enamel to specialized steel at temperatures exceeding eight hundred degrees, we create a material with unparalleled properties:

Superior Chemical Resistance: The glass interior is completely impervious to the organic acids and corrosive gases generated during the digestion of mixed biomass.

Rapid Modular Construction: The bolted design allows for significantly faster installation times compared to traditional concrete, which is vital for projects looking to meet tight commissioning deadlines.

2. Epoxy Coated Tanks: High-Performance Industrial Storage

As a critical part of our infrastructure portfolio, Center Enamel’s Epoxy Coated Tanks provide an excellent solution for various auxiliary stages of the treatment train.

Advanced Coating Technology: Our epoxy tanks utilize a high-specification electrostatic powder coating process. This results in a smooth, durable finish that provides excellent resistance against a wide range of industrial and agricultural chemicals.

Versatile Application: These tanks are ideal for equalization, storage of treated digestate, or as buffer tanks for incoming liquid feedstocks. They offer a cost-effective yet highly durable alternative where high corrosion resistance is essential.

3. Aluminum Dome Roofs: Efficient Secondary Containment

For the storage of treated liquid digestate or process water where gas capture is not the primary requirement, Center Enamel offers specialized Aluminum Dome Roofs . These self-supporting geodesic structures are used for odor control and to prevent rainwater from diluting the nutrient-rich organic fertilizer. Constructed from high-strength aluminum alloy, they are naturally resistant to corrosion and require no internal support columns.

Sustainability and Economic ROI for Integrated Projects

Implementing advanced Biogas Energy Technology through Center Enamel’s EPC services is a strategic economic decision for any modern Waste-to-Energy Project:

Energy Resilience: By integrating various feedstocks, projects are less vulnerable to the seasonal availability or price fluctuations of a single waste stream.

Waste Diversion and Savings: Facilities can offer "gate fees" for various industrial and municipal wastes, creating a secondary revenue stream while diverting organic matter from landfills.

Circular Economy: The process yields two high-value products: renewable energy and a stabilized, pathogen-free organic fertilizer (digestate), closing the nutrient loop between urban consumption and agricultural production.

Global Project Excellence: Center Enamel in Action

Our expertise in providing containment for complex, multi-feedstock energy projects is proven through successful installations:

Shandong Heze Biogas Project This major regional initiative utilized 3 units of our high-performance GFS tanks. The project successfully transforms concentrated organic residues into a stable energy stream, demonstrating the reliability of our integrated gas storage systems.

Inner Mongolia Hinggan League Bio-Natural Gas Project In a region characterized by extreme temperature fluctuations, this installation integrated 4 units of our bolted steel tanks. These vessels and their Double Membrane Roofs provide the stable environment necessary for the high-efficiency production of bio-natural gas, proving the resilience of our engineering against extreme snow loads.

Jiangsu Xuzhou Biogas Project This project involved the deployment of 4 units of our advanced containment technology. It serves as a model for how professional EPC services can be used to rapidly build the essential infrastructure needed for industrial energy recovery from diverse waste sources.

Leading the Future of Integrated Waste-to-Energy

The strategic integration of various biomass feedstocks through advanced Biogas Energy Technology represents a transformative step toward a more sustainable and resilient energy landscape. By converting a complex mix of byproducts into a renewable energy asset, Waste-to-Energy Projects can protect the local environment while securing a reliable energy future.

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are dedicated to providing the innovation and engineering excellence that make these projects a success. From our premier GFS tanks and high-performance Epoxy Coated Tanks to our specialized Double Membrane Roofs and Aluminum Dome Roofs, we offer a total containment solution designed for the future of industrial sustainability.