Transforming Agricultural Waste: Advanced Anaerobic Digestion of Cattle Manure

The global livestock industry is currently navigating a period of profound transition. As the demand for dairy and beef products continues to rise alongside a growing global population, the management of Cattle Manure has become a critical operational and environmental challenge. Historically viewed as a disposal burden and a significant source of greenhouse gas emissions, cattle residues are now being reimagined as a valuable strategic resource. Through the implementation of Advanced Anaerobic Digestion of Cattle Manure, producers can transform nutrient-rich waste into a steady supply of renewable energy and high-quality bio-fertilizer.

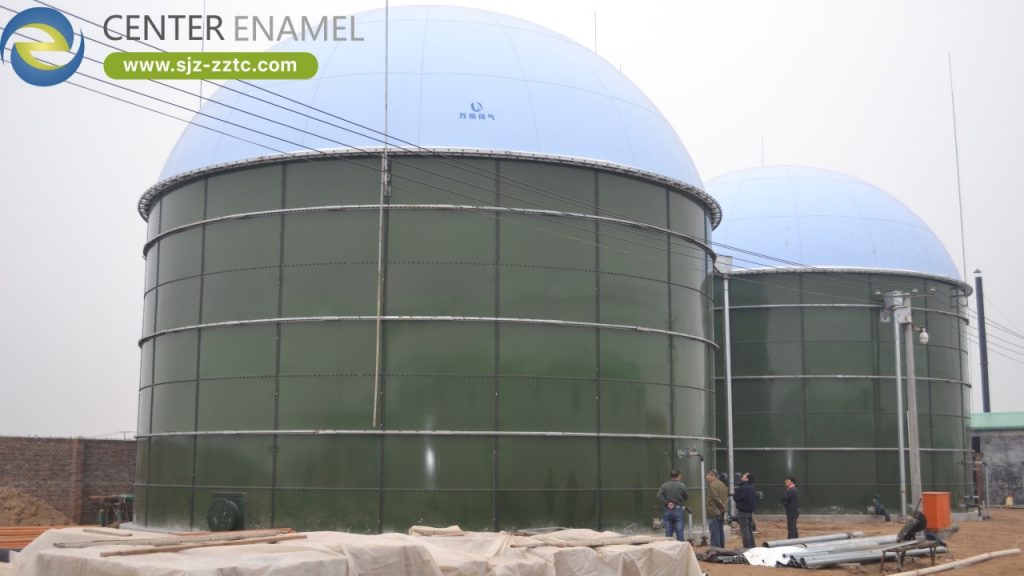

Shijiazhuang Zhengzhong Technology Co., Ltd, operating under the world-renowned brand Center Enamel, stands as a global pioneer in providing the engineering infrastructure necessary for this transition. With over thirty years of innovation and a project footprint extending to more than one hundred countries, we provide the turnkey containment and processing solutions that make high-efficiency biological recovery a reality. Our Glass-Fused-to-Steel (GFS) technology and integrated roofing systems are specifically engineered to handle the unique chemical profile of cattle waste, ensuring long-term operational success for global agricultural producers.

The Strategic Value of Cattle Manure in the Energy Loop

To optimize the Advanced Anaerobic Digestion of Cattle Manure, it is essential to understand the material's biological profile and its role in a circular economy.

1. High Organic Load and Energy Potential

Cattle Manure is characterized by a significant organic load, containing cellulose, hemicellulose, and various proteins. While it has a lower methane yield per ton compared to food waste due to its higher water and fiber content, the sheer volume produced on modern dairy and beef farms makes it an ideal feedstock for large-scale energy production. When broken down in an anaerobic environment, it yields a biogas that can be converted into electricity, heat, or renewable natural gas.

2. Environmental Mitigation

By utilizing Advanced Anaerobic Digestion of Cattle Manure, farms can achieve a dual benefit: they eliminate the release of methane from open lagoons—a gas far more potent than carbon dioxide—and mitigate the risk of nutrient runoff into local water systems. This transition is essential for farms aiming to meet carbon neutrality targets and comply with increasingly strict environmental regulations.

Technical Foundations of Advanced Anaerobic Digestion

Achieving high-efficiency recovery requires a sophisticated system designed to manage the high fiber content and variable solids concentration common in cattle operations.

1. The Biological Sequence

The Advanced Anaerobic Digestion of Cattle Manure involves four critical stages:

Hydrolysis: Breaking down complex organic polymers into simple monomers.

Acidogenesis: Converting monomers into volatile fatty acids.

Acetogenesis: Transforming acids into acetic acid, hydrogen, and carbon dioxide.

Methanogenesis: Specialized bacteria converting these intermediates into methane.

2. Process Stability and Mixing

Cattle waste often contains bedding materials like straw or sand, which can lead to settling or the formation of floating crusts. Center Enamel’s engineering solutions, particularly the Continuous Stirred-Tank Reactor (CSTR), utilize advanced mechanical mixing to ensure a homogeneous environment. This maximizes the contact between bacteria and organic matter, preventing "dead zones" and ensuring consistent gas output

Center Enamel: Engineering Excellence in Containment

At Center Enamel, we specialize in the foundational infrastructure that makes the Advanced Anaerobic Digestion of Cattle Manure both safe and profitable.

1. Glass-Fused-to-Steel (GFS) Tanks: The Industrial Standard

Our flagship GFS tanks are the global standard for cattle waste reactors. By fusing a high-tech glass enamel coating to specialized steel at temperatures exceeding 800 degrees, we create a material with unparalleled properties:

Corrosion Resistance: The internal environment of a manure digester is highly aggressive. The glass surface of our tanks is completely inert, providing total resistance to organic acids and hydrogen sulfide.

Hardness and Abrasion Resistance: Cattle Manure can be abrasive due to grit. Our GFS coating scores a 6.0 on the Mohs scale, ensuring the tank walls remain undamaged over decades of service.

Modular Assembly: Our bolted design allows for rapid on-site assembly, which is essential for busy farm environments where construction footprints must be minimized.

2. Integrated Gas Management with Double Membrane Roofs

To maximize energy utilization, Center Enamel provides integrated gas storage through our Double Membrane Roofs. The flexible inner membrane functions as a variable-volume gas holder, while the pressurized outer membrane provides a protective structural shell against wind, rain, and snow.

3. Aluminum Dome Roofs: Maintenance-Free Longevity

For the storage of treated digestate or process water, our Aluminum Dome Roofs offer an unparalleled solution.

Geodesic Durability: Constructed from high-strength aluminum alloy, these domes require no internal support columns. This maximizes the usable volume of the tank and provides a permanent, maintenance-free seal.

Resource Protection: They prevent the dilution of nutrient-rich bio-fertilizer by rainwater, ensuring the final product remains at a high concentration for field application.

Sustainability and the Circular Economy

Investing in Advanced Anaerobic Digestion of Cattle Manure is a strategic decision that delivers significant long-term value.

Energy Self-Sufficiency: Replacing purchased grid electricity or fossil fuels with self-generated biogas provides immediate savings and protection from energy market volatility.

Nutrient Valorization: The digestate remaining after the process is a stabilized, organic fertilizer that can be returned to the fields, closing the nutrient loop and improving soil health.

Carbon Footprint Reduction: Capturing methane and displacing fossil fuels allow agricultural operations to qualify for international carbon credits and improve their sustainability ratings.

Global Project Excellence: Center Enamel in Action

Our reputation as a world leader is built on a foundation of successful projects in over one hundred countries. The following non-fictitious projects highlight our capacity to deliver infrastructure for high-efficiency energy recovery from organic waste:

Shandong Heze Biogas Project This regional energy initiative utilized 3 units of our high-performance GFS tanks. The project successfully transforms agricultural and livestock residues into a stable energy stream, demonstrating the reliability of our tanks in large-scale energy recovery operations.

Inner Mongolia Hinggan League Bio-Natural Gas Project A landmark project in a challenging climate, this installation successfully integrated 4 units of our bolted steel tanks. These vessels provide the stable environment necessary for the high-efficiency production of bio-natural gas from Cattle Manure, proving the resilience of our engineering against extreme temperature fluctuations.

Jiangsu Xuzhou Biogas Project This major industrial project involved the deployment of 4 units of our advanced GFS containment technology. The project serves as a prime example of how modular construction can be utilized to rapidly build the essential infrastructure for modern, large-scale anaerobic digestion facilities.

Driving the Future of Livestock Sustainability

The implementation of Advanced Anaerobic Digestion of Cattle Manure represents one of the most effective pathways toward a sustainable agricultural industry. By converting a waste liability into a renewable energy asset, producers can secure their energy future while fulfilling their environmental responsibilities.

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are dedicated to providing the innovation and engineering excellence that make these projects a success. From our premier GFS tanks to our specialized Double Membrane Roofs and Aluminum Dome Roofs, we offer a total containment solution designed for the future of industrial sustainability.