- About Us

-

Solutions

EPC Projects

Anaerobic Processes Package

-

Equipments

Project Equipment Package

Processes Equipment Package

Storage Tanks

- Project Reference

- Download

- News

- Contact Us

Zhengzhong Technology (Center Enamel) continues to carry out innovative research and development around sewage treatment technology and equipment. It has mastered a number of core technologies and processes in the field of industrial wastewater treatment, and has the strong advantages on projects, technology and service. The company integrates sewage treatment with enterprise production closely, adopts the optimal technological solutions, improves the effect and operational efficiency of sewage treatment, and comprehensively solves sewage problems for customers in the pharmaceutical, brewery, pulp and paper,soft drink and other industries.

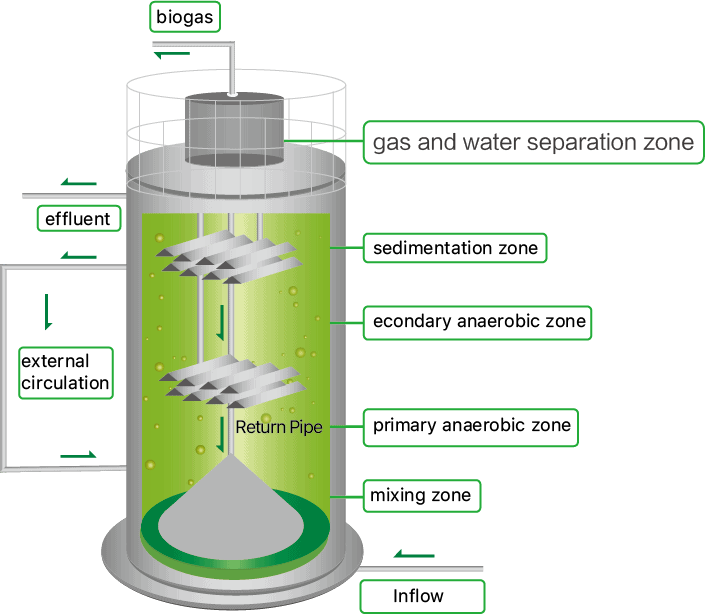

In the anaerobic process section of industrial wastewater treatment, IC process (Internal Circulation Anaerobic Bioreactor) is usually adopted. IC reactor is a new generation of high-efficiency anaerobic reactor. It consists of mixing zone, primary anaerobic zone, secondary anaerobic zone, sedimentation zone and gas-liquid separation zone. It is the anaerobic reactor with the highest efficiency in sewage treatment at present. IC process mainly used in the treatment of high-concentration organic wastewater. It enhances the mass transfer process of the internal circulation through high energy consumption. It is widely used in the wastewater treatment of brewery, pharmaceutical, and paper industries, etc, which can effectively reduce operating costs and improve efficiency. This is one of the important methods using to solve the problem of environmental pollution.

Applicable to urban environment, small footprint, without odor, saving investment cost.

Applicable to urban environment, small footprint, without odor, saving investment cost.

Vertical tank with complete size options, easy to install.

Vertical tank with complete size options, easy to install.

Powerful resistance to impact load ,stable in operation, Stable effluent quality.

Powerful resistance to impact load ,stable in operation, Stable effluent quality.

Short hydraulic retention time, possess an apparent advantage over UASB.

Short hydraulic retention time, possess an apparent advantage over UASB.

Using a three-phase separator to optimize the retention of microorganisms.

Using a three-phase separator to optimize the retention of microorganisms.

Reliable self-adjusting internal circulation system to save energy.

Reliable self-adjusting internal circulation system to save energy.

The GFS tank is used as the reactor, which is corrosion-resistant and has a service life of over 30 years.

The GFS tank is used as the reactor, which is corrosion-resistant and has a service life of over 30 years.

Convert organic components into valuable biogas, reduce emission costs as well as lower energy costs.

Convert organic components into valuable biogas, reduce emission costs as well as lower energy costs.

Project Location: Chongqing city, China

Process: IC reactor * 6 sets

Treatment capacity: 6000 tons/day

Project Location: Zhejiang province, China Process: IC Treatment capacity: 1000 tons/day

Project Location: Hebei Province, China Process: IC

Project Location: Hubei Province, China Process: IC Treatment capacity:1500 tons/day